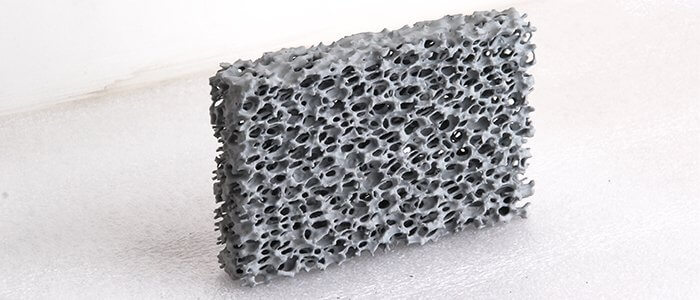

Silicon carbide ceramic foam filters have long been valued in the metallurgical industry for their exceptional ability to filter molten metal. However, a groundbreaking new application has emerged, showcasing the versatility of these filters. In an innovative move, silicon carbide filters are being employed to trap dust and impurities in heating equipment, significantly enhancing efficiency and performance.

The Evolution of Silicon Carbide Filter:

Traditionally known for their use in the casting industry to filter molten metal, silicon carbide filters have transformed. This evolution stems from recognizing the unique properties of these filters, such as their high-temperature resistance, thermal stability, and exceptional porosity.

Addressing Challenges in Heating Equipment:

Heating equipment, whether in industrial settings or residential heating systems, often faces challenges related to the accumulation of dust and impurities. Over time, these contaminants can degrade the efficiency of the equipment, reduce heat transfer capabilities, and even lead to potential malfunctions. Introducing silicon carbide ceramic foam filters presents an effective solution to mitigate these issues.

How Silicon Carbide Filter Work in Heating Equipment:

Silicon carbide filters act as highly effective filtration media due to their intricate network of interconnected pores. When integrated into heating equipment, these filters function as a barrier, capturing and trapping dust particles, soot, and impurities in the air or fuel. This prevents the contaminants from entering sensitive components of the heating system.

Enhancing Efficiency and Longevity:

By incorporating silicon carbide filters, heating equipment experiences improved efficiency and prolonged operational life. The filters not only prevent the accumulation of dust and impurities but also contribute to maintaining optimal combustion conditions. This results in cleaner combustion, reduced emissions, and a more energy-efficient heating process.

Reducing Maintenance Requirements:

One of the notable advantages of utilizing silicon carbide ceramic foam filters in heating equipment is the reduction in maintenance requirements. The filters can be easily replaced or cleaned, extending the intervals between maintenance cycles. This not only saves time and resources but also enhances the overall reliability of the heating system.

Applications Across Industries:

The application of silicon carbide filters in heating equipment extends across various industries, including manufacturing, energy production, and residential heating. From industrial furnaces to residential boilers, the versatility of these filters makes them adaptable to a wide range of heating systems.

Environmental Impact:

The use of silicon carbide filters in heating equipment not only benefits operational efficiency but also aligns with environmental sustainability goals. Cleaner combustion and reduced emissions contribute to a greener and more environmentally friendly heating process.

Conclusion:

The integration of silicon carbide filters for trapping dust and impurities in heating equipment marks a transformative leap in the functionality of these filters. Beyond their traditional role in metallurgy, these filters now play a pivotal role in enhancing the efficiency, longevity, and environmental impact of heating systems across diverse industries. As technology continues to evolve, silicon carbide ceramic foam filters exemplify how innovation can unlock new possibilities in unexpected domains, ushering in a new era of performance and sustainability.