In modern industry, porous ceramics have become one of the core materials in the fields of metallurgy, environmental protection, new energy, etc. due to their excellent high temperature resistance, chemical stability and adjustable pore structure. As a company deeply engaged in the research and development and production of high-performance ceramics, we have always been committed to providing customers with efficient and reliable porous ceramic solutions through innovative processes. The following analyzes the core manufacturing logic of porous ceramics from the dimensions of preparation technology and application.

Preparation Process of Porous Ceramics

The preparation of porous ceramics needs to take into account both pore structure design and material performance optimization. Its core process can be divided into three stages:

Raw material selection and formula design

Select high-purity oxides (such as alumina, zirconium oxide, silicon carbide, cordierite, mullite, etc.) as the main materials, accurately control the powder particle size and activity, and ensure the stability of the matrix after sintering. For different application scenarios, sintering aids (such as yttrium oxide, magnesium oxide) or pore-forming agents can be added in combination to achieve a balance between mechanical properties and porosity.

Molding process selection

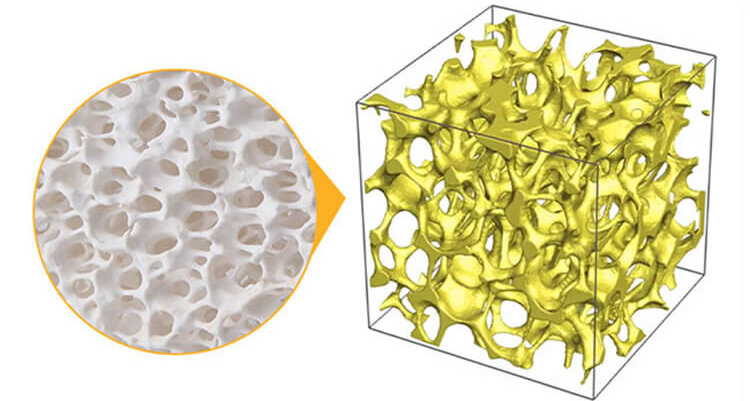

- Foam impregnation method: organic polymer foam (such as polyurethane) is impregnated into ceramic slurry, and the slurry is evenly attached to the three-dimensional mesh skeleton. After drying and sintering, an open-pore structure with high porosity is formed. This process is particularly suitable for the production of ceramic foam filters with high filtration accuracy and excellent air permeability.

- Direct foaming method: adding a foaming agent (such as protein or chemical reagent) to the ceramic slurry, generating bubbles through mechanical stirring or chemical reaction, forming a multi-level pore with closed and open pores, which is suitable for lightweight thermal insulation materials.

- 3D printing molding: With the help of digital modeling, ceramic slurry is stacked layer by layer, which can realize the customized design of complex pore structure and meet the needs of high-end fields such as aerospace.

Sintering process optimization

Adopt a staged temperature control strategy:

- The low temperature stage (400-800℃) is slowly heated to remove organic matter;

- The medium and high temperature stage (1200-1600℃) accelerates the densification process and finally forms a stable crystal phase.

Precise control of sintering temperature and time directly affects pore connectivity, strength and corrosion resistance.

Core technology breakthrough: dual improvement of performance and efficiency

Precise control of pore structure

By adjusting the type, particle size and addition ratio of the pore-forming agent, or optimizing the foaming process parameters, the pore customization from micron to millimeter level can be achieved to meet the filtering, catalysis or sound absorption requirements of different scenarios.

Composite reinforcement technology

Introducing nanoparticles or fiber reinforcement phases into the matrix can improve thermal shock resistance and compressive strength while maintaining high porosity. For example, after silicon carbide porous ceramics are reinforced with carbon fibers, the fracture toughness is increased by more than 30%, which is suitable for extreme high temperature environments.

Green manufacturing innovation

Using industrial solid waste (such as fly ash and metallurgical slag) to replace some raw materials, combined with low-temperature sintering technology, can reduce energy consumption and production costs, while reducing resource consumption.

Industrial Application Scenarios and Value

The unique properties of porous ceramics make them the “invisible hero” of many industries:

- Casting purification: Foam ceramic filters can intercept slag and oxides in molten metal, improving the surface finish and mechanical properties of castings;

- Environmental governance: Porous ceramics with high specific surface area are widely used as catalyst carriers in automobile exhaust purification and industrial waste gas treatment;

- Energy storage: The three-dimensional interconnected pore structure provides efficient mass transfer channels for electrode materials of fuel cells and lithium-ion batteries.

Conclusion

As an innovator in the field of porous ceramics, we are always customer-oriented and continuously optimize product performance through material research and development and process upgrades. From raw material selection to intelligent sintering production lines, each link is subject to strict quality control to ensure that each porous ceramic delivered has both excellent functions and long-term stability. In the future, we will further explore the application potential of porous ceramics in emerging fields such as hydrogen energy and semiconductors, and provide stronger support for global industrial upgrades.

About Us

We focus on the research and development and production of high-performance ceramic materials. Our products include a series of porous ceramics such as zirconium oxide, silicon carbide, and aluminum oxide, which are widely used in casting, environmental protection, new energy and other fields. Relying on advanced preparation technology and global supply chain, we are committed to providing customers with cost-effective customized solutions.

- Email: info@sf-foundry.com

- WhatsApp Number: +86 13785803358