Correct installation of the ceramic foam filter is essential to ensure its filtering effect and extend its service life. The following are the installation steps and precautions:

How To Use Ceramic Foam Filters? Installation Steps

Preparation:

Check the filter: Make sure there is no damage or cracks.

Clean the pouring system: Remove impurities and old filter materials from the pouring cup, pouring channel, etc.

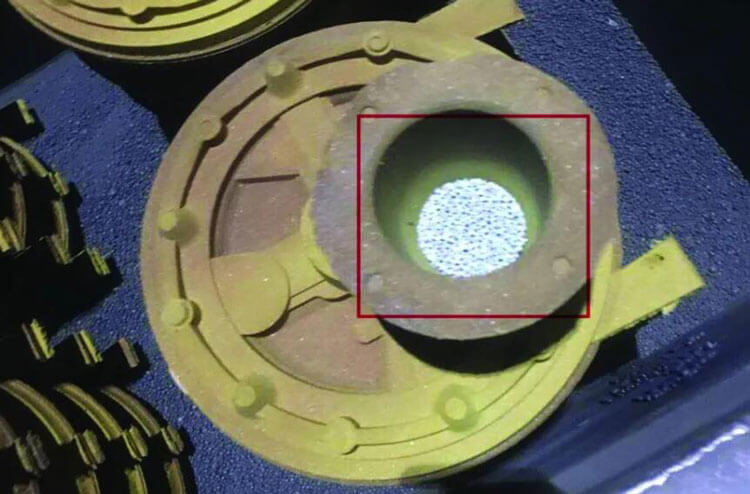

Place the filter:

Choose a location: Usually placed at the bottom of the pouring cup or in the pouring channel.

Fixing: Use refractory mud or ceramic fiber mat to fix it to ensure stability and no gaps.

Install the pouring system:

Assemble: Assemble the pouring cup, pouring channel and other components in sequence to ensure that the filter is in the correct position.

Seal: Make sure that each connection is well sealed to prevent molten metal from leaking.

Preheating:

Preheat the filter: Preheat to 200-300°C after installation to avoid thermal shock.

Preheat the pouring system: Preheat as a whole to reduce temperature differences.

Pouring:

Control the flow rate: Maintain an appropriate flow rate to avoid excessive shock.

Monitoring: Observe the pouring process to ensure that the filter works properly.

Notes

Size matching:

Ensure that the filter size matches the pouring system to avoid being too large or too small.

Avoid mechanical damage:

Handle with care to prevent collision or falling.

Preheating temperature:

The preheating temperature should not be too high to prevent the filter from cracking.

Pouring temperature:

Control the temperature of the molten metal to avoid being too high or too low.

Regular replacement:

Check and replace the filter regularly to ensure the filtering effect.

Maintenance and care

Residue cleaning:

Clean the residue on the surface of the filter after use to prevent clogging.

Storage:

Store in a dry and ventilated place to avoid moisture or contamination.

In summary, the correct installation and maintenance of the foam ceramic filter can effectively improve the filtering effect and service life and ensure the quality of metal castings.

Are you looking for a reliable ceramic foam filter manufacturer? SF-FOUNDRY is a ceramic foam filter manufacturer. Choose SF-FOUNDRY to be your reliable supplier.

Email: info@sf-foundry.com

Call/WhatsApp: +8613785803358