Impurities such as oxides, slag, and non-metallic inclusions in aluminum liquid will seriously affect the mechanical properties, processing properties, and surface quality of aluminum alloy castings. With the continuous improvement of the quality requirements of aluminum alloy castings in the automotive, aerospace, and electronics industries, how to efficiently remove impurities in aluminum liquid has become one of the core issues in the casting process.

As a professional casting material supplier, SF-Foundry has long been committed to the research of aluminum alloy melt purification technology, providing high-performance alumina foam ceramic filters to help customers optimize casting processes and improve casting quality. In this article, we systematically analyze the sources of impurities in aluminum alloy casting and how to remove them.

Sources of impurities in aluminum alloy casting and their hazards

Sources of impurities

In the process of aluminum alloy smelting and casting, impurities in aluminum liquid mainly come from the following aspects:

Raw materials brought in: aluminum ingots, scrap aluminum, and alloy additives may contain impurities such as scale, oil, and sand.

The smelting process produces:

- Alumina (Al₂O₃): When the aluminum liquid contacts the air, an oxide film will form on the surface, which may be drawn into the melt during stirring or pouring.

- Flux residue: If the refining agent and covering agent are not completely removed, non-metallic inclusions may be formed.

- Furnace lining erosion: The refractory material enters the aluminum liquid after peeling.

Pollution during the pouring process: The transfer pour ladle, launder, and pouring system may introduce secondary oxidation inclusions.

Hazards of impurities

The impact of these impurities on the quality of castings cannot be ignored.

- Degradation of mechanical properties: Inclusions become stress concentration points, reducing the tensile strength, elongation and fatigue life of castings.

- Processing defects: During subsequent rolling, forging or machining, impurities may cause problems such as cracks and peeling.

- Poor surface quality: Porosity and slag inclusions appear on the surface of the casting, affecting the appearance and corrosion resistance.

Key links for removing impurities in aluminum alloy casting

In the aluminum alloy casting process, aluminum water purification is a systematic project. Impurity control needs to run through the entire process of smelting, liquid transfer, and pouring. The main links include:

- Smelting stage: remove most inclusions through refining and degassing.

- Aluminum Liquid transfer/standing stage: let large particles of impurities settle naturally.

- Pouring stage: use ceramic filters to intercept tiny inclusions to ensure that pure aluminum liquid enters the cavity.

Among them, pouring filtration is the last and most critical purification barrier, which directly affects the quality of castings.

Main methods for removing impurities from Aluminum Liquid

Melting purification technology

Inert gas refining (such as Ar, N₂):

- Introduce inert gas to form bubbles, adsorb inclusions and float to the liquid surface.

- Applicable to remove hydrogen and tiny oxides.

Flux purification:

- Use chloride or fluoride salt flux (such as NaCl+KCl) to react with impurities to form a slag phase and then remove it.

- It should be noted that flux residue may introduce new inclusions.

Sedimentation and Filtration

Natural Sedimentation:

- After the aluminum liquid is left to stand, impurities with higher density (such as TiB₂, SiC) will sink, but tiny oxides are difficult to completely remove.

Aluminum Filtration:

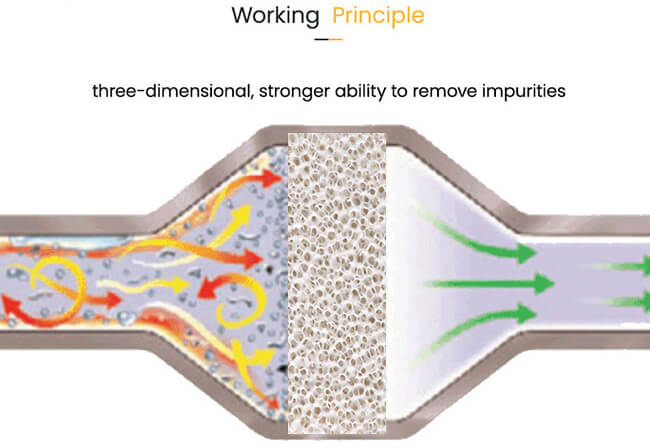

- Principle: Use a foam ceramic filter to mechanically intercept inclusions using a three-dimensional mesh structure, while stabilizing the flow of aluminum liquid to reduce secondary oxidation caused by turbulence.

- Advantages: It can remove inclusions above 10μm, with a filtration efficiency of more than 90%, suitable for high-demand castings (such as automobile wheels, aviation parts).

Online Processing Technology

- Rotary Degassing (RDU): Use degassing rotors, etc., combined with rotary blowing and inert gas, to efficiently remove impurities and hydrogen.

- CFF (Ceramic Foam Filter) System: Integrate a foam ceramic filter in the casting launder to achieve continuous filtration.

Application of Foam Ceramic Filters in Aluminum Alloy Casting

Advantages of Alumina Foam Ceramic Filters

As the core product of SF-Foundry.com, alumina ceramic foam filters have the following characteristics:

- High porosity (75-85%): ensure high flow and high efficiency filtration.

- High temperature resistance (1250℃): suitable for aluminum alloy pouring temperature (700-800℃).

- Multiple aperture selection (10-60 PPI): adapt to different casting process requirements.

How to choose a suitable casting filter

| Casting process | Recommended PPI | Applicable scenarios |

|---|---|---|

| Sand casting | 10-20 | Large flow pouring, primary filtration |

| Metal mold casting (automotive parts) | 20-30 | Balance filtration accuracy and flow rate |

| Precision casting (thin-walled parts) | 40-60 | Extremely high purity requirements, such as aluminum foil, electronic parts |

Precautions for use

- Correct installation: Make sure the filter matches the pouring system to avoid aluminum liquid bypass.

- Preheating treatment: preheat at 300-500℃ for 1-2 hours to prevent thermal shock cracking.

- Replacement cycle: single use to avoid the risk of blockage caused by repeated use.

Future development trend

- Compound filtration technology: coarse filtration + fine filtration combination to improve filtration efficiency.

- Intelligent monitoring: combine sensors to detect filter status in real time and optimize replacement timing.

- Environmentally friendly flux: reduce environmental pollution during the refining process.

Conclusion

In aluminum alloy casting, impurity control is the key to ensuring the quality of castings. The alumina foam ceramic filter provided by SF-Foundry has become the preferred solution for many high-end casting companies with its efficient filtration capacity and stable performance. Through reasonable smelting purification, sedimentation treatment and precision filtration, the purity of aluminum liquid can be significantly improved to meet the needs of automotive, aviation, electronics and other industries for high-quality aluminum alloy castings.

If you need to further optimize your casting process, please contact SF-Foundry, we will provide you with professional technical support and customized filtration solutions.

- Email: info@sf-foundry.com

- WhatsApp: +8613785803358