If you’ve ever worked with metal castings, you’ve likely battled shrinkage. It’s the number one cause of those frustrating defects like cavities and porosity that can scrap an otherwise perfect part. Over my years on the foundry floor, I’ve learned that understanding shrinkage isn’t just academic—it’s the key to producing high-quality, sound castings every time.

A question I hear often from new engineers and clients is: “Just how many types of shrinkage do we actually need to worry about?”

The straightforward answer is three. But each type happens at a different stage of the cooling process and requires a unique solution. Let’s break them down.

The 3 Types of Shrinkage in Metal Casting

Liquid Shrinkage

This is where it all begins. Liquid shrinkage occurs while the metal is still fully molten, from the moment it leaves the ladle until it starts to solidify at what we call its liquidus temperature.

What’s Happening: The liquid metal is simply cooling down. As it does, its molecules lose energy and move closer together, causing the volume to decrease.

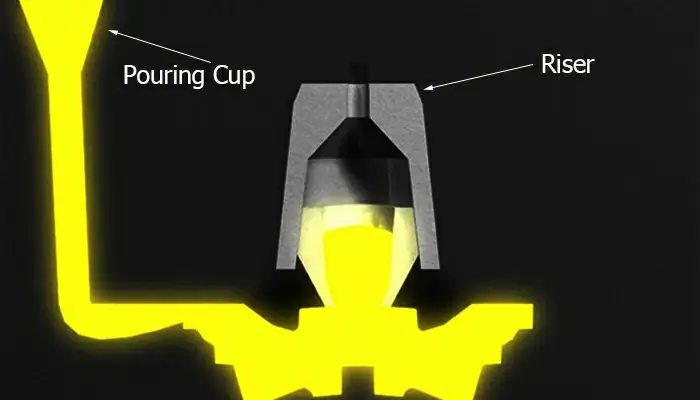

How We Compensate: This is the easiest type to manage. We account for it automatically by using a pouring basin and a sprue. These components are designed to hold extra molten metal that feeds into the mold cavity as the initial pour shrinks.

Solidification Shrinkage (The Most Critical One)

This is the big one—the shrinkage that causes the most headaches. It occurs while the metal is transforming from a liquid into a solid, passing through a “mushy” state between the liquidus and solidus temperatures.

What’s Happening: Most metals (like steel and aluminum) actually take up less space as a solid than they do as a liquid. This phase change creates a significant volume deficit.

How We Compensate: This is why we use feeders (also called risers). These are reservoirs of molten metal designed to be the last part of the casting to solidify. They feed liquid metal into the main casting to “fill in the gaps” left by this phase change. Getting the riser design wrong is, in my experience, the most common reason for major shrinkage cavities.

Solid Shrinkage (Patternmaker’s Shrinkage)

Finally, after the metal is 100% solid, it continues to contract as it cools down to room temperature. This is known as solid shrinkage.

What’s Happening: It’s basic thermal contraction—the same principle that causes railroad tracks to expand on a hot day. The solid part is just getting smaller as it cools.

How We Compensate: We don’t use risers for this. Instead, we make the pattern oversized. We use special shrink rules that are intentionally longer than a standard ruler by a specific percentage (e.g., 2.1% for steel). This ensures the final casting cools down to the exact dimensions we need.

A Quick Reference Table

| Type of Shrinkage | When It Occurs | How to Manage It |

|---|---|---|

| Liquid Shrinkage | While completely molten | Pouring basin & sprue |

| Solidification Shrinkage | During freezing (Liquid → Solid) | Feeders (Risers) |

| Solid Shrinkage | After solidification (Cooling to room temp) | Oversized pattern |

A Quick Tip from the Foundry Floor

Beyond these three, watch out for microporosity. This isn’t a fourth type of shrinkage, but a nasty defect caused by solidification shrinkage in alloys with a long freezing range. If the liquid metal can’t flow through the mushy zone to feed tiny pockets, you get scattered porosity. The fix? Often, it’s about improving the feeding distance or using chills to directionally solidify the casting.

The Bottom Line

So, how many types of shrinkage are there? Three: Liquid, Solidification, and Solid. Each one is managed at a different stage of the process—through the sprue, the risers, and the pattern design.

Understanding this distinction is what separates a failed casting from a flawless one. By designing your feeding system and pattern to address each type sequentially, you can consistently produce dense, defect-free parts.

Have a specific shrinkage problem you’re trying to solve? Feel free contact us to share your challenge!