Ceramic foam is a versatile material used in various industries. Its durability depends on multiple factors. Understanding its lifespan helps in proper application.

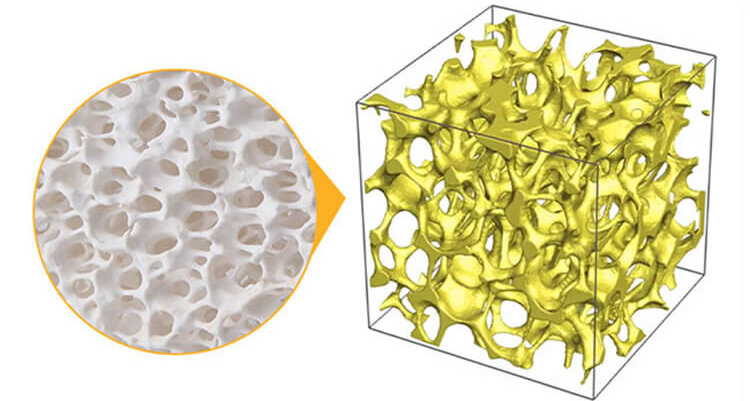

Composition and Structure

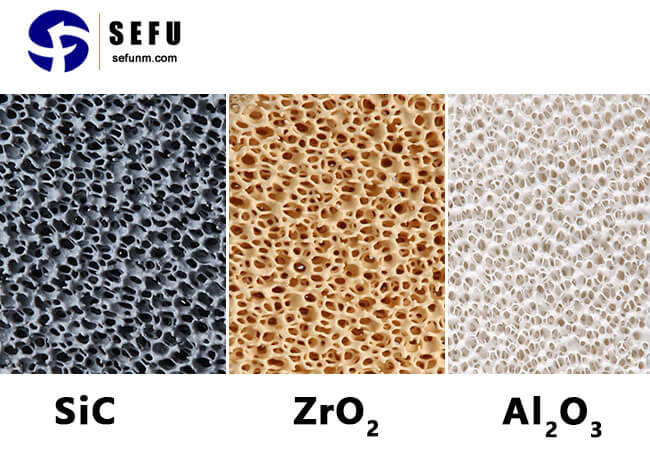

The composition of ceramic foam greatly influences its lifespan. It is typically made from alumina, zirconia, or silicon carbide. The porous structure provides high thermal resistance. However, the open-cell design can also be a weak point.

Features

Temperature Resistance

Ceramic foam excels in high-temperature environments. It can withstand extreme heat without melting. Prolonged exposure to very high temperatures may cause gradual degradation. Thermal cycling can also lead to micro-cracks over time.

Chemical Stability

Chemical exposure affects ceramic foam’s durability. It resists most acids and alkalis well. Harsh chemicals can still corrode its surface. The rate of chemical attack depends on concentration and temperature.

Impact conditions

Mechanical Stress

Physical impacts reduce ceramic foam’s service life. It has good compressive strength but low tensile strength. Vibrations and sudden shocks can cause fractures. Proper handling minimizes mechanical damage.

Manufacturing Quality

Production methods determine initial quality. High-quality raw materials enhance durability. Precise manufacturing controls reduce defects. Poor quality foam fails prematurely.

Load Conditions

Operating loads affect service duration. Constant heavy loads cause faster deterioration. Light intermittent use prolongs life. Matching capacity to application is crucial.

Moisture Exposure

Water absorption can weaken ceramic foam. Some types resist moisture better than others. Prolonged wet conditions promote degradation. Drying cycles may cause structural damage.

Oxidation Effects

High temperatures accelerate oxidation. Oxidation weakens the ceramic structure. Protective coatings can slow this process. Some formulations resist oxidation naturally.

Conclusion

The lifespan of ceramic foam varies significantly depending on material composition, operating conditions, and maintenance practices. Proper selection—considering factors such as pore structure, thermal stability, and chemical resistance—can greatly extend its service life. Environmental influences, including temperature fluctuations, corrosive atmospheres, and mechanical stress, play a critical role in degradation over time. However, with diligent care, regular inspections, and timely replacements when necessary, ceramic foam can deliver reliable performance for many years, making it a cost-effective solution for filtration, insulation, and other industrial applications.SEFU has been committed to winning the field of foam ceramic filters with a variety of raw materials, providing customers with high-quality and efficient filtering experience