During the aluminum alloy casting process, even micron-level impurities may cause cracking, pores or performance defects in the casting. The Alumina Ceramic Foam Filter, with its unique three-dimensional skeleton structure and dual filtration mechanism, has become the core barrier for aluminum liquid purification, accurately intercepting impurities in the turbulence of high-temperature molten metal, and protecting the quality of precision castings in aerospace, automobile manufacturing and other fields.

Alumina Ceramic Foam Filter Structure

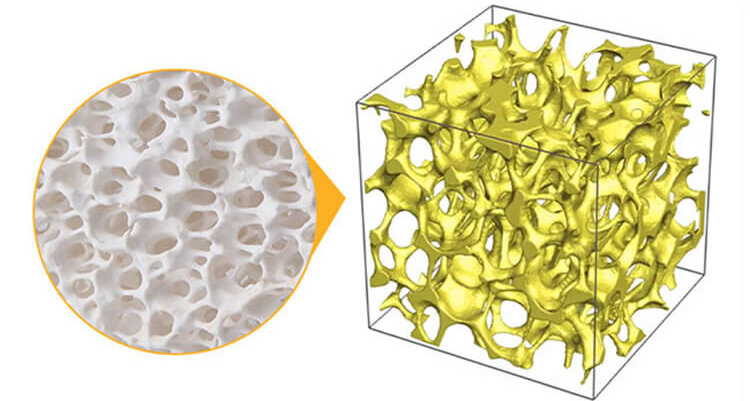

The core advantage of the Alumina Ceramic Foam Filter comes from its precise three-dimensional mesh structure design. Using the porous form of high-quality polyurethane organic sponge, the high-purity alumina slurry is consolidated into a stable skeleton network through a high-temperature sintering process.

Uniform pore design: The pores distributed in the skeleton form a coherent “three-dimensional channel”, which allows aluminum liquid to pass smoothly and effectively intercepts impurity particles of different sizes;

Adaptive diversion: The three-dimensional network can disperse the impact force of aluminum liquid, reduce secondary oxidation caused by turbulence, and prolong the contact time between metal and filter material to improve purification efficiency.

This structure is like designing a “smart maze” for aluminum liquid, where impurities are screened layer by layer, while pure metal flows calmly to the next link.

Filtration mechanism of alumina ceramic foam filter plate

Alumina foam ceramic filter plate does not simply rely on pore size to “screen” out impurities, but combines physical interception and chemical adsorption to achieve efficient purification:

Mechanical screening

When aluminum liquid flows through the filter plate, larger oxide lumps and slag particles are directly blocked by the pores of the three-dimensional skeleton, just like fishing with a fishing net to complete the initial interception.

Surface adsorption

Alumina materials have strong adsorption capacity for micron-level or even submicron-level fine impurities (such as flux residues and hydroxides). These impurities are firmly “locked” on the pore surface to prevent them from entering the casting mold with the aluminum liquid and forming defects.

Synergistic advantages: The two mechanisms complement each other, which can not only deal with the diverse impurities mixed in the aluminum liquid, but also adapt to different casting flow and temperature conditions to ensure filtration stability.

Performance of alumina ceramic foam filter

The temperature of aluminum liquid is usually above 700℃, and ordinary materials are easy to soften and deform or even contaminate the metal. The excellent performance of alumina foam ceramic filter plate is inseparable from the inherent advantages of its material itself:

High temperature stability: The melting point of alumina (Al₂O₃) exceeds 2000℃, and it maintains structural integrity during aluminum liquid casting to avoid cracking or releasing harmful substances at high temperatures;

Thermal shock resistance: The unique sintering process gives the filter plate the characteristics of rapid adaptation to temperature changes, and repeated use from room temperature to high temperature will not produce microcracks.

This feature makes it a “reliable barrier” under extreme working conditions, especially suitable for scenes with strict requirements on metal purity such as aerospace turbine blades.

Technical value of alumina ceramic foam filter

The application of alumina foam ceramic filter plate has completely changed the limitations of traditional casting that relies on passive purification methods such as sedimentation and flotation:

Improve the yield rate: reduce defects such as pores and slag inclusions in castings, and reduce the scrap rate;

Extend equipment life: Pure aluminum liquid reduces corrosion and wear on molds and flow channels;

Energy saving and consumption reduction: Shorten subsequent processing steps, reduce energy consumption and material waste.

As a certain automotive parts manufacturer reported: “After using alumina filter plates, our engine cylinder yield rate has increased by 18%, saving more than one million yuan in costs each year.”

Conclusion

The alumina foam ceramic filter plate seems simple, but it embodies the multidisciplinary wisdom of materials science, fluid mechanics and precision manufacturing. From structural design to process optimization, every detail points to the same goal-making metals purer and manufacturing more efficient.

With the surge in demand for lightweight aluminum alloys in industries such as new energy vehicles, this technology will continue to drive the global precision casting industry towards high quality and sustainability.