For both ceramic filters for casting, would you choose straight-channel honeycomb ceramic filters or foam ceramic filters? The choice of different casting filters directly affects the quality of castings and production efficiency. As a manufacturer that has been studying molten metal filtration materials for a long time, we have studied these two solutions many times to help foundries achieve a perfect balance between filtration efficiency and metal flow characteristics.

Differences and similarities between honeycomb ceramic filters and foam ceramic filters

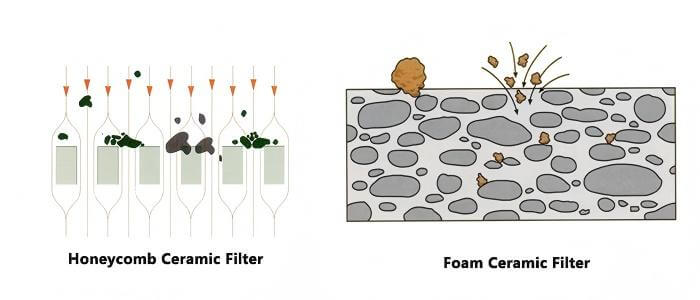

Let’s first get to know these two casting ceramic filters:

The straight-channel honeycomb filter uses a carefully designed vertical channel with low flow resistance and high flux. It is particularly suitable for large-flow casting scenarios (such as large castings or high-speed production lines). It can effectively filter impurities while maintaining a stable metal liquid flow rate.

The foam ceramic filter uses a curved three-dimensional mesh porous structure to achieve deep filtration through tortuous channels, with higher interception efficiency, and is particularly suitable for precision castings with strict requirements for inclusion control (such as automotive parts, aerospace parts, etc.).

The core difference between the two is that the straight hole type focuses on the balance between flow and efficiency, while the foam type emphasizes extreme filtration; but both have ceramic properties such as high temperature resistance and thermal shock resistance, and can be flexibly selected according to the casting material (aluminum/iron/steel), process requirements and defect types.

Technology Selection Guide

Our research shows the best application parameters:

For aluminum castings:

When the slag content exceeds 0.3% (by weight), use foam filters (20-30ppi)

For high pressure die casting runners, use honeycomb filters (100-200cpsi)

For iron castings:

SiC foam (10-15ppi) can withstand typical 2-5kg/s pouring speeds

Honeycomb alumina maintains thermal shock resistance in automatic production lines

Foundry Ceramic Filter Manufacturer

As a foundry ceramic filter manufacturer, SF-Foundry provides you with a variety of foundry filters, whether it is honeycomb ceramic filters or foam ceramic filters, whether it is for cast iron, cast aluminum, cast steel, or cast copper, you can choose the most suitable porous ceramic filter for you at SF-Foundry.

Contact SF-Foundry now to design the perfect filtration solution for you.