Introduction

In the ever-evolving landscape of materials science, ceramic foam filters stand as a testament to human ingenuity and technological advancement. These intricate structures, with their porous architecture and exceptional properties, have become integral components in a multitude of industries. One of the most remarkable traits that sets ceramic filters apart is their high-temperature resistance. This article aims to delve deep into the world of ceramic filters, unraveling the science behind their ability to withstand extreme heat, and exploring their diverse applications across industries.

The Essence of Ceramic Foam Filters

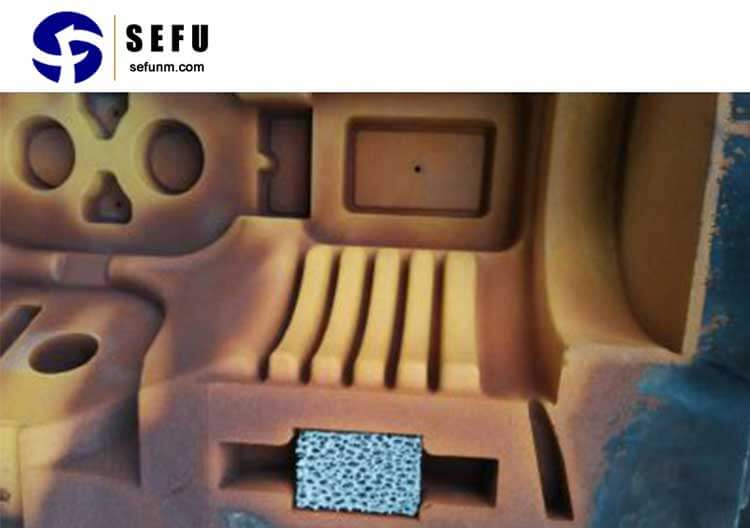

Ceramic foam filters are three-dimensional structures, meticulously designed to balance porosity with mechanical strength. They are predominantly crafted from various ceramic materials such as alumina, silicon carbide, zirconia, and combinations thereof. The manufacturing process is a symphony of innovation, where a ceramic slurry is artfully impregnated onto a polyurethane foam template. The subsequent steps of drying, sintering, and the removal of the foam template unveil the intricate porous matrix, creating a ceramic foam filter.

Unraveling High-Temperature Resistant Mechanisms

The awe-inspiring high-temperature resistance exhibited by ceramic foam filters can be attributed to a symphony of underlying mechanisms:

Melting Point and Thermal Stability: At the heart of ceramics lies their intrinsic property of having incredibly high melting points and remarkable thermal stability. This inherent characteristic ensures that ceramic filters maintain their structural integrity even when subjected to extreme temperatures.

Oxidation Resistance: The very nature of ceramics renders them highly resistant to oxidation. In scenarios where intense heat could trigger rapid oxidation of other materials, ceramic foam filters thrive, retaining their form and function.

Structural Integrity: The ingenious cellular architecture of ceramic filters plays a pivotal role in their high-temperature resilience. The interconnected pores create a convoluted network that facilitates uniform heat distribution and minimizes the risk of thermal stress-induced fractures.

Applications Across Industries

The high-temperature resistant trait of ceramic foam filters renders them indispensable in a multitude of industries, where extreme heat and challenging conditions prevail:

Foundry Industry: In the realm of metal casting, ceramic filters find their calling. These filters act as gatekeepers, meticulously removing impurities and entrapped gases from molten metal. Withstanding the scorching heat of molten alloys, ceramic filters contribute to enhanced casting quality and robust outcomes.

Steel Production: The crucible of steel production is another arena where ceramic foam filters shine. They play an instrumental role in purifying liquid steel, ridding it of inclusions and contaminants. This contribution to steelmaking processes showcases the resilience of ceramic filters in the face of extreme temperatures.

Molten Metal Filtration: Industries working with molten metals, be it aluminum, copper, or nickel, reap the benefits of ceramic filters. These filters not only elevate the quality of the end product by eliminating undesirable particles but also augment the mechanical properties of the final material.

High-Temperature Chemical Processes: The realm of high-temperature chemical processes beckons ceramic foam filters due to their ability to withstand intense thermal environments. They find applications in catalytic reactions, gas separation, and other processes where extreme heat tolerance is imperative.

The Future Beckons

The journey of ceramic foam filters is far from over. As the wheels of innovation continue to turn, these filters are poised to find novel applications and undergo further enhancements. Research into new ceramic materials, improved manufacturing techniques, and innovative designs promises to push the boundaries of their high-temperature resistance even further.

Challenges and Future Prospects of Ceramic Foam Filters

While ceramic foam filters indeed showcase exceptional high-temperature resistance, challenges persist. The intricate manufacturing process, while yielding remarkable results, can be resource-intensive. Furthermore, the quest to enhance the filters’ mechanical strength without compromising their porosity presents an ongoing challenge.

The future, however, is bright. Researchers and engineers are actively exploring ways to optimize the production process, reduce energy consumption, and expand the spectrum of ceramic materials suitable for filter construction. As industries continue to demand solutions that can withstand the rigors of high-temperature environments, ceramic filters will likely take center stage.

Innovations in Ceramic Foam Filters

The realm of ceramic foam filters is not stagnant; it’s a realm of constant innovation. Researchers are ceaselessly pushing the boundaries to unlock new potential and applications for these high-temperature resistant powerhouses.

Advanced Manufacturing Techniques: As additive manufacturing gains ground, its potential impact on ceramic foam filter production is being explored. 3D printing allows for intricate designs and precise control over pore sizes, opening doors to custom filters tailored for specific applications.

Nanotechnology Integration: The integration of nanotechnology into ceramic foam filters introduces a new dimension. Nanoscale coatings and reinforcements can enhance filter performance, improve chemical resistance, and further elevate their high-temperature capabilities.

Hybrid Materials: Researchers are delving into the world of hybrid materials by combining ceramics with other high-performance materials like metals or polymers. This fusion aims to harness the strengths of different materials, resulting in filters with enhanced mechanical, thermal, and chemical properties.

Multi-Functional Filters: The concept of multi-functional ceramic filters is emerging. These filters could potentially combine not only filtration capabilities but also catalytic, photocatalytic, or even energy storage functionalities, making them versatile assets in various industries.

Sustainability and Environmental Impact

In an era where sustainability takes center stage, ceramic foam filters also have a role to play. Their durability and ability to withstand extreme conditions translate to longer lifecycles, reducing the frequency of replacements and associated waste. Furthermore, the efficient filtration they provide can lead to reduced waste and improved resource utilization in various processes.

Challenges on the Horizon

Despite their remarkable qualities, ceramic foam filters are not without challenges:

Cost Considerations: The intricate manufacturing process and the use of specialized ceramic materials can contribute to higher production costs. Balancing cost-effectiveness without compromising quality remains a challenge.

Material Diversity: While ceramics like alumina and silicon carbide dominate the scene, exploring other materials that exhibit both high-temperature resistance and improved filtration capabilities is an ongoing pursuit.

Scaling Up Production: Transitioning from laboratory-scale production to large-scale industrial applications can be a complex endeavor. Ensuring consistency in quality and performance on a larger scale is a challenge that manufacturers continue to grapple with.

Ceramic Foam Filters in Aerospace and Energy Industries

The aerospace and energy sectors are also reaping the benefits of ceramic foam filters’ high-temperature resistance. In gas turbine engines, these filters play a crucial role in removing contaminants from air and fuel, ensuring optimal combustion efficiency. Additionally, ceramic filters have found their way into high-temperature fuel cells, contributing to the production of clean energy.

Education and Research

The academic community plays a vital role in advancing the field of ceramic foam filters. Research endeavors delve into understanding the finer nuances of their behavior under extreme conditions, exploring novel materials, and refining manufacturing techniques. The insights gained from such studies have a ripple effect, enhancing the performance and applicability of ceramic filters across industries.

A Future Beyond Boundaries

As industries evolve and technology propels us forward, the potential applications of ceramic foam filters continue to expand. From aerospace and energy to biotechnology and even space exploration, their high-temperature resistance and filtration capabilities will make them indispensable tools in addressing the challenges of the future.

Conclusion

The journey of ceramic foam filters from their creation to their widespread application in industries around the world is a testament to human innovation and perseverance. Their high-temperature resistant trait, grounded in the synergy of ceramic materials, intricate structure, and scientific understanding, has unlocked possibilities that were once deemed unattainable. From enhancing the quality of metal castings to revolutionizing clean energy production, ceramic filters are writing a story of innovation, resilience, and progress. As we stand on the brink of new discoveries and technological breakthroughs, one can only imagine the heights these remarkable structures will ascend to in the pursuit of excellence.