Ceramic foam filters and pouring cups play a crucial role in optimizing the metal pouring process. They have revolutionized metal casting processes, improving the quality of castings by efficiently removing impurities during pouring.

Ceramic Foam Filters

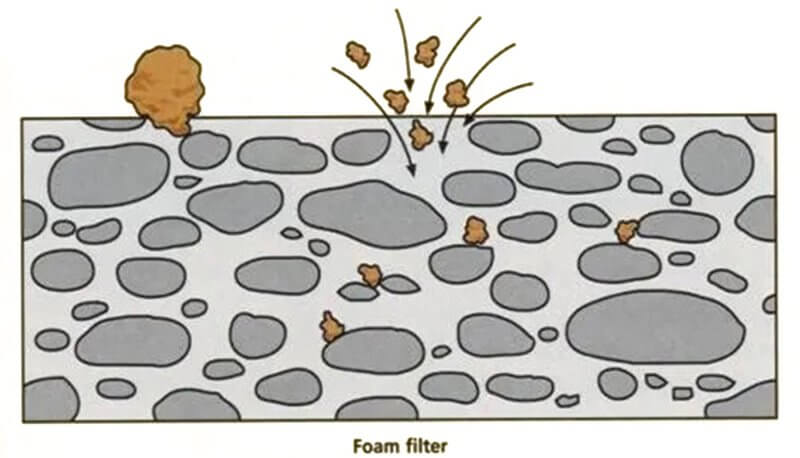

Ceramic foam filters have revolutionized metal casting processes, improving the quality of castings by efficiently removing impurities during pouring. These innovative filters, made from a high-porosity ceramic material, provide a unique combination of mechanical strength and thermal resistance that makes them ideal for use in demanding casting applications. By effectively capturing and removing unwanted solid particles and gas bubbles, ceramic foam filters contribute to the production of flawless castings with enhanced mechanical properties.

Pouring Cups for Casting

In synergy with ceramic foam filters, the design and utilization of pouring cups play a crucial role in optimizing the metal pouring process. Pouring cups, often crafted from refractory materials, serve as the entry point for molten metal into the mold cavity. Their design influences the flow of metal, helping to minimize turbulence and prevent the re-entrainment of impurities that can compromise the integrity of the casting. To ensure maximum efficiency, pouring cups are often integrated with ceramic foam filters, creating a comprehensive system that works harmoniously to produce high-quality castings.

Relationship of Ceramic Foam Filters and Pouring Cups for Casting

The collaboration between ceramic foam filters and pouring cups is based on the fundamental principle of reducing turbulence and preventing the introduction of impurities during metal pouring. As molten metal flows from the pouring cup into the mold, ceramic foam filters positioned within the cup capture particulates and gas bubbles, preventing their entry into the mold cavity. This dual-layer defense mechanism ensures that the cast metal maintains its purity and quality, ultimately yielding castings with fewer defects and improved mechanical properties.

Furthermore, the proper integration of ceramic foam filters and pouring cups can contribute to energy savings and cost efficiency in the metal casting process. By reducing the need for excessive rework and the use of additional materials, manufacturers can optimize their operations, streamline production, and achieve consistent results.

In conclusion, ceramic foam filters and pouring cups form a symbiotic relationship that is central to the advancement of metal casting techniques. The innovative capabilities of ceramic foam filters to capture impurities and gas bubbles complement the role of pouring cups in guiding molten metal with minimal turbulence. This collaboration not only enhances the quality of castings but also promotes efficiency and cost-effectiveness within the casting industry. As technology continues to evolve, the synergy between ceramic foam filters and pouring cups will undoubtedly play a pivotal role in shaping the future of metal casting.

In the intricate dance of metal casting, ceramic foam filters and pouring cups stand as the guardians of casting quality, ensuring that only the finest molten metal flows into the waiting mold.