B-type Exothermic Riser Sleeve for Steel Casting - SEFU ceramic

SEFU’s B-type riser sleeves are designed to be used in steel casting production. They minimize the risk of shrinkage and slug collection during the casting process. Available in a range of sizes, these riser sleeves accommodate both small and large casting needs.

- Strictly tested and examined.

- Reduce consumption.

- Improve the process of yields.

- Save energy.

- Reduce the repair areas of the casting.

- Product Specifications

- Our Factory

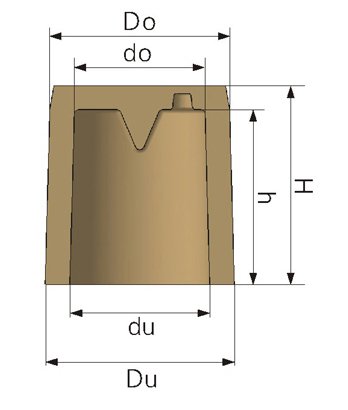

| Specification/Model (du*H) |

Effective modulus (cm) |

Riser size (mm) | Volume (CC) | |||||

| du | Du | do | Do | h | H | |||

| B4/7 | 1.20 | 41.5 | 62.5 | 35.5 | 59 | 63 | 71.5 | 70 |

| B5/8 | 1.50 | 52 | 73.5 | 48 | 70 | 70 | 80 | 130 |

| B6/9 | 1.70 | 57.5 | 80 | 52.5 | 76 | 78.5 | 91 | 180 |

| B7/10 | 2.00 | 69.5 | 94 | 65 | 89 | 87 | 99 | 300 |

| B8/11 | 2.25 | 79 | 102 | 71.5 | 99 | 96.5 | 108 | 420 |

| B9/12 | 2.50 | 89 | 119 | 81 | 110 | 104.5 | 120 | 580 |

| B9/18 | 2.68 | 89 | 119 | 81 | 110 | 164.5 | 180 | 890 |

| B10/13 | 2.80 | 97 | 127.5 | 91 | 119.5 | 118 | 133 | 800 |

| B11/14 | 2.91 | 108 | 138 | 101 | 130 | 123 | 140 | 1000 |

| B12/15 | 3.20 | 118 | 154.5 | 112 | 148 | 130 | 150 | 1350 |

| B14/17 | 3.73 | 140 | 182 | 131 | 173 | 149 | 170 | 2140 |

Please contact our customer service for more product specifications.

B-type riser sleeves are compact, cylindrical-shaped auxiliary components used in steel casting. Made from low-density, highly refractory materials, these sleeves provide low thermal conductivity, allowing them to retain heat effectively. Available in various forms such as open-ended, domed, and blind versions, these feeder sleeves are suitable for casting steel with volumes up to 2140 cc.

When molten metal begins to solidify too quickly, the riser sleeve enhances thermal retention, countering rapid cooling and reducing the risks of shrinkage, cavities, or slag formation in the steel casting.

Advantages of SEFU’s B-type feeder sleeves:

- Low thermal conductivity and superior thermal insulation.

- Simplified removal post-casting through techniques such as hammering—eliminating the need for grinding and cleaning.

- Prevention of local cracks and casting defects during gas-cutting.

- Minimal air volume and controlled breathability.

Application

- Steel Casting: Engine blocks, gears, and structural parts

- Iron Foundries: Pipes and automotive components

- Industrial Components: Valves and turbine blades

- Steel Alloys: Aerospace and chemical industry equipment requiring high-temperature casting

Features & Benefits

SEFU’s vacuum-formed exothermic sleeves are tailored to enhance the solidification of molten metal, helping to prevent shrinkage defects and cavities that could lead to additional processing work.

- Solid thermal insulation prevents the casting materials from experiencing a chilling effect. It helps maintain consistent thermal retention during the casting process.

- B-Type sleeves are available in various shapes and sizes to accommodate small to moderate casting requirements.

- High refractoriness ensures that the sleeves resist expansion or deformation at elevated temperatures.

- The fire-resistant properties of the riser enable it to withstand extreme temperatures ranging from 1400 to 1600°C. It is crucial for continuous metal feeding and preventing premature solidification.

- It provides high shrinkage efficiency

Why choose SEFU CERAMIC?

As a leading manufacturer and distributor of foundry sleeves, we offer a wide range of auxiliary components for foundry practices and supply for more than 20 countries. When you choose SEFU for exothermic riser sleeves, you’re opting for a manufacturer that provides:

- A wide range of size and shape options for casting sleeves

- Customized packaging in compliance with regulations

- ISO-accredited, tested products that ensure the highest heating efficiency

- A variety of other products that enhance foundry practices, including ceramic filters, cutting and grinding tools, and spruce runner systems

- 24/7 customer support

- Free samples to try

FAQs About the Foundry Sleeves

SEFU integrates the production of exothermic riser sleeves, ceramic pouring cups, ceramic filters, and various casting materials. We are dedicated to researching foundry solutions that improve the quality and yield of castings.

We look forward to you exploring more foundry solutions with us.

The material properties, thermal insulation, and design of the B-type sleeves are optimized for effectiveness in steel casting.

Choose the right sleeves for your casting material—for instance, B-type for iron and steel. Calculate the modulus, fluid volume, and the number of riser sleeves required. Keep in mind that larger riser sleeves can handle higher casting demands.