The casting market in Indonesia has been growing rapidly over the past few years, driven by the expansion of infrastructure, construction, and automotive sectors. However, with growth comes challenges, and the casting industry is no exception. One of the most significant issues faced by the industry is the quality of casting products manufactured. To produce high-quality castings, it is essential to control the quality of the molten metal and filter out impurities that can affect the properties of the final product. In this regard, foam ceramic filters have emerged as a popular solution among foundries in Indonesia. In this article, we will take a closer look at the casting market in Indonesia and the market analysis of foam ceramic filters.

Casting Market in Indonesia

Indonesia is the largest economy and the fourth most populous country in the world, with a population of over 273 million people (World Bank, 2021). The Indonesian economy has recorded steady growth over the past decade, with an average GDP growth rate of 5.2% from 2010 to 2020 (World Bank, 2021). The manufacturing sector has been one of the key drivers of economic growth, accounting for over 20% of the country’s GDP in 2019 (Statista, 2021). Within the manufacturing sector, the casting industry plays a vital role, supplying critical components to various downstream industries such as automotive, construction, and machinery.

The casting industry in Indonesia comprises small- and medium-sized foundries that produce a range of cast products, including iron castings, steel castings, aluminum castings, and copper castings. According to the Indonesian Foundry Industries Association (APLINDO), there are about 253 foundries in Indonesia, employing over 13,000 workers (APLINDO, 2019). The majority of these foundries are located in West Java, Central Java, and East Java, where there is a high concentration of industrial activities.

The Indonesian casting market is projected to grow at a compound annual growth rate (CAGR) of 6.4% from 2020 to 2025, driven by the expansion of the automotive and construction sectors (ResearchAndMarkets, 2021). The construction sector is expected to remain the largest end-user of castings, followed by automotive and machinery industries.

Market Analysis of Foam Ceramic Filters in Indonesia

The quality of castings depends on several factors, including the quality of the raw materials, the casting process, and the quality of the molten metal. Molten metal is prone to impurities that can affect the mechanical properties and the surface finish of the final product. One of the most common impurities in molten metal is oxide inclusions, which can form during the melting process or by exposure to air. To remove these impurities, foundries use filters made of different materials, such as sand, ceramic, or graphite.

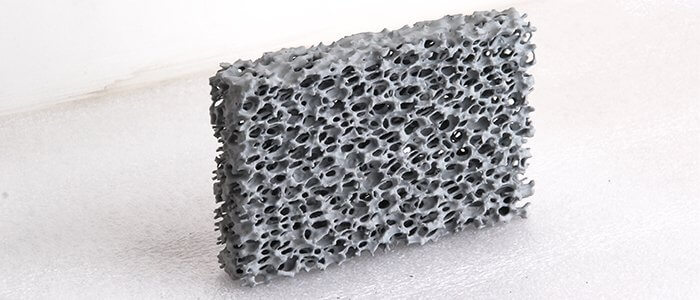

Foam ceramic filters have gained popularity among foundries in Indonesia due to their superior filtering efficiency and mechanical strength. Foam ceramic filters, also known as ceramic foam filters, are made of an open-cell ceramic foam structure that allows the molten metal to flow through while trapping impurities. They are available in different grades to suit various casting applications.

The foam ceramic filter market in Indonesia is still in the growth stage, with a few key players dominating the market. Some of the leading manufacturers of foam ceramic filters in Indonesia include PT. Imexco Rekayasa Engineering, PT. Bukaka Teknik Utama Tbk, and PT. Keramika Indonesia Assosiasi. These companies supply foam ceramic filters to foundries across Indonesia, catering to different casting applications.

The foam ceramic filter market in Indonesia is projected to grow at a CAGR of 6.2% from 2020 to 2025, driven by the increasing demand for high-quality castings (ResearchAndMarkets, 2021). The growth of the foam ceramic filter market is also supported by the growth of the casting industry in general, as more foundries adopt advanced filtering technologies to improve their casting quality.

Conclusion

The casting industry in Indonesia is a critical player in the Indonesian manufacturing sector, supplying components to various downstream industries. However, the quality of castings produced by foundries is crucial to the success of downstream businesses. Foam ceramic filters have emerged as a popular solution among foundries in Indonesia to improve the quality of their castings. The foam ceramic filter market in Indonesia is expected to grow in tandem with the growth of the casting industry. As the industry continues to mature, there will be opportunities for new entrants and existing players to expand their market share by providing innovative solutions that meet the evolving demands of the market.