It is well known that impure molten aluminum affects the quality of the final aluminum casting. Oxide inclusions, slag particles and other contaminants can lead to increased porosity, reduced mechanical strength and surface defects that often require expensive rework or result in the scrapping of the part. Fiberglass mesh filters are a popular molten metal filtration solution for aluminum foundries seeking to improve metal quality without complex equipment or excessive cost.

As an experienced foundry filter material manufacturer, SF-Foundry understands the critical balance between molten metal filtration efficiency and production practicality. Our fiberglass filters meet the needs of modern aluminum casting processes, providing effective impurity removal while maintaining smooth metal flow.

Why need Molten Metal Filtration in Aluminium Casting?

Aluminium casting involves melting and pouring aluminium alloys into molds to form components for automotive, aerospace, and industrial applications. However, during melting, handling, and pouring, the molten metal can absorb impurities such as:

- Oxides (Al₂O₃) – Formed due to exposure to air.

- Slag & Flux Residues – Leftover from refining processes.

- Refractory Particles – Erosion from furnace linings.

- Sand Inclusions – From mold materials in sand casting.

If these impurities are not removed, they can result in inclusions and slag defects in the final casting, resulting in reduced mechanical properties of the casting. The use of fiberglass mesh filters acts as a barrier to capture these impurities before the metal enters the mold cavity.

How Molten Metal Filtration Works

When molten aluminum is exposed to air during transfer and pouring, a thin oxide layer naturally forms on its surface. These aluminum oxide particles, as well as other non-metallic inclusions, become suspended in the melt. For these impurities, traditional methods such as fluxing and degassing can remove some, but usually leave some fine particles that conventional technology cannot capture.

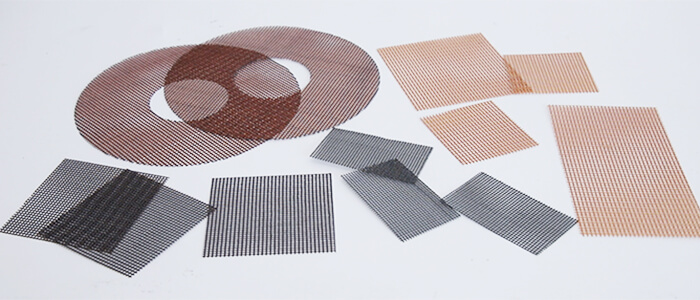

The working principle of fiberglass mesh filters is to capture inclusions larger than their pore size particles through different pore sizes, while allowing clean metal to pass through.

Application of Fiberglass Mesh Filters for Molten Aluminium Filtration:

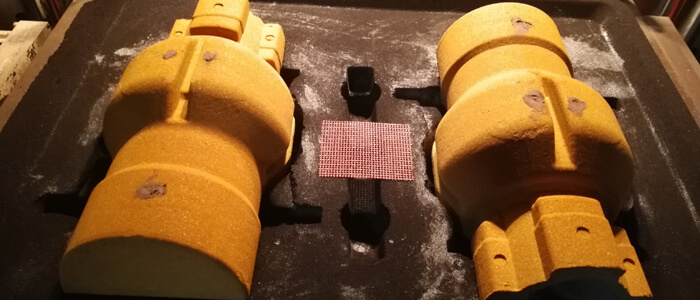

Different casting processes have different requirements for filters. In sand casting, mesh filters are usually set at the cross runner of the pouring system, which can filter impurities and reduce sand erosion. For metal mold casting, we recommend setting the mesh filters at the pouring cup, which can not only ensure the purity of the metal, but also improve the stability of filling.

Precision casting has the highest requirements for metal purity, and the use of cap-type filters has a significant effect. The application data of an aviation blade manufacturer shows that the use of an optimized filtration system can significantly improve the internal qualification rate of castings.

The selection of filters needs to comprehensively consider factors such as casting structure and alloy characteristics. In general, filters with a pore size of 1.5×1.5mm are suitable for most aluminum castings, while high-end applications such as aerospace require finer filtration of 1.0×1.0mm.

Note when installing:

- Use special tools to cut to ensure smooth edges

- Accurately position at the turning point of metal flow

- Properly embed sand in sand casting

Conclusion

Fiberglass mesh filters are a proven, economical solution for improving molten aluminium quality in casting processes. By effectively removing oxides, slag, and other impurities, they enhance mechanical properties, reduce defects, and increase production efficiency.

For foundries seeking reliable filtration solutions, SF-Foundry’s fiberglass filters provide an optimal balance of performance, durability, and ease of use.

Contact SF-Foundry today to discuss your aluminium casting filtration needs.

- Email: info@sf-foundry.com

- WhatsApp: +8613785803358