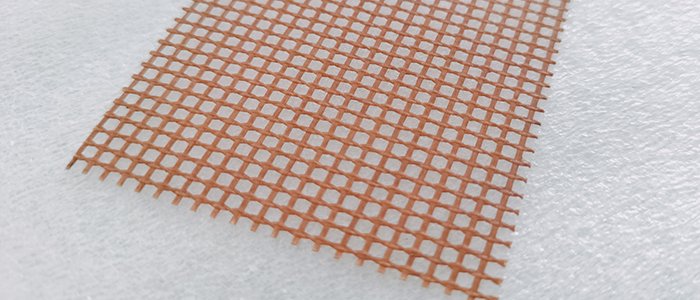

Fiberglass mesh filter plays an important role in the field of casting. It is widely used to improve the quality and efficiency of casting processes by removing impurities from molten metal before it is poured into the mold. The filter is often made into various shapes of filter caps, and some filters also need to go through other technologies, such as smoke-free treatment, to ensure their effectiveness.

Function of Fiberglass Mesh Filter

The main function of glass fiber filters is to trap impurities in the molten metal, such as dross, oxide, and other debris. They work by creating a tortuous path for the metal to flow through, with the filter media acting as a barrier to trap impurities. The filters are typically made from a synthetic fiber material, such as glass fiber, and are available in different grades and pore sizes to suit different casting applications.

Advantages of Fiberglass Mesh Filter

One of the key advantages of Fiberglass Mesh filters is their ability to reduce casting defects. By removing impurities from the molten metal, filters can help to reduce the likelihood of defects such as porosity, shrinkage, and inclusions. This results in higher-quality finished products, which are more reliable and consistent.

Variety

Fiberglass Mesh Filter is available in a range of shapes and sizes to suit different casting applications. Some filters are designed to be placed directly in the gating system of the casting mold, while others are used as standalone filters that can be inserted into the molten metal as it is poured. There are also disposable and reusable filters, depending on the casting process.

Additional processing

To ensure the effectiveness of glass fiber filters, it is important to use other technologies, such as smoke-free treatment. This process involves the removal of any organic matter or binders that may be present in the filter media, which can cause smoke during the casting process. Smoke can not only be a nuisance to workers, but it can also contaminate the metal and result in casting defects.

In conclusion, Fiberglass Mesh filter is essential to the casting process. Its ability to remove impurities from molten metal helps to improve the quality and efficiency of casting processes, resulting in higher-quality finished products. By using the right filter for the right application and ensuring that filters go through the appropriate smoke-free treatment, casters can achieve consistent and reliable results for their customers.