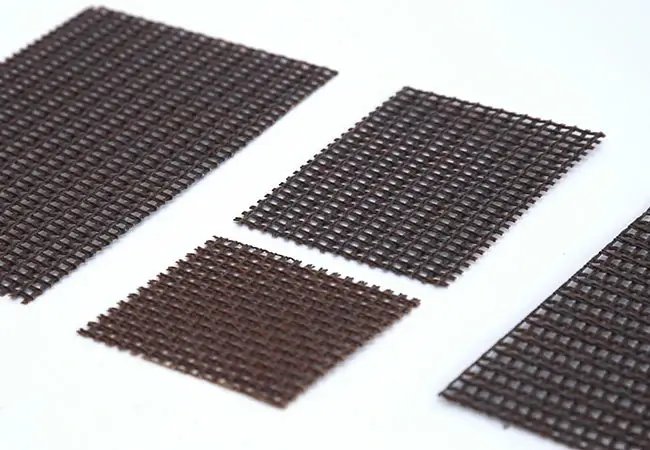

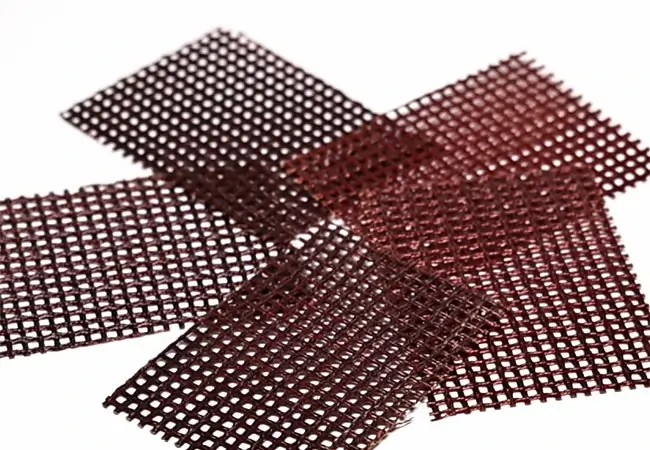

Filter Mesh: High-Temperature Filtration for Molten Steel

SF-Foundry Filter Mesh provides a definitive, cost-effective solution. Engineered specifically for the thermal and chemical demands of molten steel, it acts as a reliable in-gate sieve, capturing harmful inclusions to deliver cleaner metal and more predictable results in investment and sand casting.

- Technical Specifications: Precision for Demanding Applications

| Parameter | Steel Mesh Filter Specification | Notes for Steel Founders |

|---|---|---|

| Material Composition | High-Silica Amorphous Glass Fiber | Optimized for thermal shock resistance and chemical stability in ferrous melts. |

| Effective Working Temperature | 1550°C – 1620°C (2822°F – 2948°F) | Specifically validated for carbon and low-alloy steel pouring ranges. |

| Maximum Thermal Exposure | Up to 1650°C (3002°F) for short-term pouring. | Safely accommodates superheat during transfer and pour. |

| Standard Mesh Size (Aperture) | 1.5mm x 1.5mm, 2.0mm x 2.0mm, 2.5mm x 2.5mm | Targets macro-inclusions and larger micro-inclusions; balances filtration and flow. |

| Standard Sheet Dimensions | 150mm x 150mm, 200mm x 200mm, 300mm x 300mm | Compatible with common gating designs. Custom sizes available. |

| Key Metallurgical Benefit | Chemically Inert – Will not introduce aluminum or other elements into melt. | Critical for preserving precise steel chemistry. |

| Primary Process Compatibility | Investment Casting, Sand Casting | Ideal for precision and general steel foundry applications. |

Cut to size and place securely in the sprue base or runner of the gating system. Use a small amount of high-temperature refractory adhesive or a designed ceramic holder to prevent displacement.

Pouring steel demands precision and certainty. Inclusions—deoxidation alumina, fragmented slag, and eroded refractory—compromise integrity, lead to catastrophic machining failure, and undermine the performance of high-value components. SF-Foundry Refractory Fiberglass Mesh Filter for Steel Casting is a precision-woven mesh manufactured from ultra-high-purity, high-silica amorphous glass fibers. This specific formulation is designed to maintain structural integrity and filtration efficiency at the intense temperatures of molten steel, offering a practical filtration barrier where options are limited and failures are costly.

Why Filtration is Non-Negotiable in Steel Casting?

-

Inclusion Criticality: Fine alumina clusters from deoxidation can create fatal stress points.

-

Machining Protection: Hard inclusions rapidly destroy cutting tools, escalating costs.

-

Yield Assurance: A single inclusion can scrap a high-value casting, making prevention essential.

High Temperature Mesh Filter Advantage

While aluminum and iron filters operate on similar principles, steel filtration exists in a different regime. Our Fiberglass Mesh Filter is designed for this gap:

- Thermal Endurance: It survives where standard fiberglass meshes degrade, providing a reliable physical barrier at steel pouring temperatures.

- Flow Management: The calibrated mesh provides predictable resistance, helping to calm the metal stream in pressurized gating systems common in steel investment casting.

- Practical Economics: For many steel applications, it offers a drastically more cost-effective and easier-to-use alternative to ceramic foam filters without the fragility, preheating requirements, or contamination risk in re-melt.

What Types of Steel Castings Can Use a Filter Mesh?

SF-Foundry Refractory Cloth Filter Mesh is specified for components where quality is paramount:

-

Industrial & Pump/Valve: Pump casings, valve bodies, fluid end components.

-

Machinery & Automotive: High-strength gears, drive components, hydraulic parts.

-

General Engineering: High-stress structural castings and wear parts.

SF-Foundry Commitment for Your Steel Casting Process

Every batch of Fiberglass Filter Screen is quality-controlled for consistency. We provide transparent performance data and support to ensure it integrates seamlessly into your specific steel casting process, from trial to full production.

Ready to Add a Reliable Layer of Defense to Your Steel Casting Process?

Move beyond uncertain workarounds. Implement a metal filtration step designed for the reality of molten steel.

[Contact Our Technical Team] to discuss your alloy and casting process for a tailored recommendation.