Zirconia ceramic (ZrO. 2), also known as zirconium oxide ceramic, stands out as a versatile material with a myriad of applications across various industries. Its unique properties make it a material of choice for a wide range of uses, from biomedical to industrial applications.

Understanding Zirconia ZrO. 2 Ceramic

Zirconia ceramic is a type of ceramic material known for its exceptional properties, including high strength, hardness, wear resistance, biocompatibility, and thermal stability. These characteristics make it a preferred material in many industries where performance and reliability are paramount.

Applications of Zirconia ZrO. 2 Ceramic

1. Biomedical Applications:

In the field of medicine, zirconia ceramic is extensively used for dental implants, crowns, and bridges due to its biocompatibility and durability. Its resemblance to natural teeth and corrosion resistance make it a popular choice in dentistry.

2. Industrial Components:

Zirconia ceramic finds applications in various industrial components such as wear-resistant parts, insulating materials, refractory linings, and crucibles. Its high temperature resistance and chemical inertness make it ideal for demanding industrial environments.

3. Electronics and Technology:

In the electronics industry, zirconia ceramic is utilized for manufacturing capacitors, sensors, insulators, and substrates. Its dielectric properties, thermal stability, and resistance to electrical conductivity make it an essential material in electronic devices.

4. Abrasives and Cutting Tools:

Zirconia ceramic is used in the production of abrasives like grinding wheels and cutting tools due to its hardness, toughness, and ability to maintain sharp edges even under high temperatures.

5. Other Applications:

Apart from the mentioned fields, zirconia ceramics are also employed in thermal barrier coatings, fuel cells, and as a diamond simulant in jewelry.

Characteristics of Zirconia ZrO. 2 Ceramic

- High Strength and Hardness: Zirconia ceramic exhibits exceptional strength and hardness, making it suitable for high-wear applications.

- Biocompatibility: Its biocompatibility makes it an ideal material for medical implants and devices.

- Thermal Stability: Zirconia ceramic can withstand high temperatures, making it suitable for use in demanding thermal environments.

- Chemical Inertness: The material is chemically inert, making it resistant to corrosion and chemical reactions.

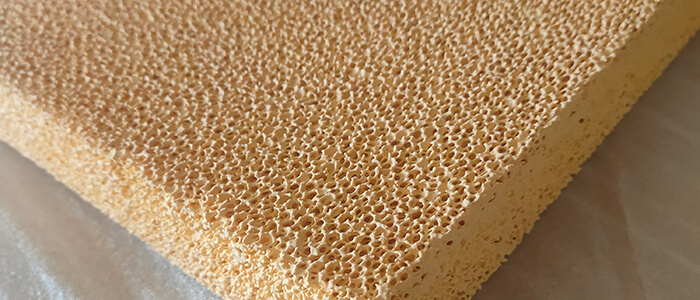

Zirconia ZrO. 2 Ceramic in Filtration

In the domain of filtration, zirconia ZrO. 2 ceramic foam filters play a crucial role in metal casting processes. These filters, alongside zirconia ceramic filters, aid in purifying metal solutions, enhancing casting quality, optimizing process efficiency, and showcasing the material’s versatility in various applications.

In conclusion, zirconia ceramic’s diverse applications and exceptional properties make it a material of choice in various industries, showcasing its importance and versatility in modern technology and manufacturing processes.