Introduction:

Ceramic materials have been utilized for various applications due to their exceptional properties, such as high-temperature resistance, chemical stability, and mechanical strength. The introduction of porosity to ceramics has unlocked a range of advantages and expanded their utility in diverse industries. Porous ceramic materials offer unique characteristics and benefits that make them desirable for numerous applications. In this article, we will delve into the advantages of porous ceramic material, exploring its enhanced functionality, improved performance, and broader applicability.

I. Understanding Porous Ceramic Material:

A. Porosity Definition:

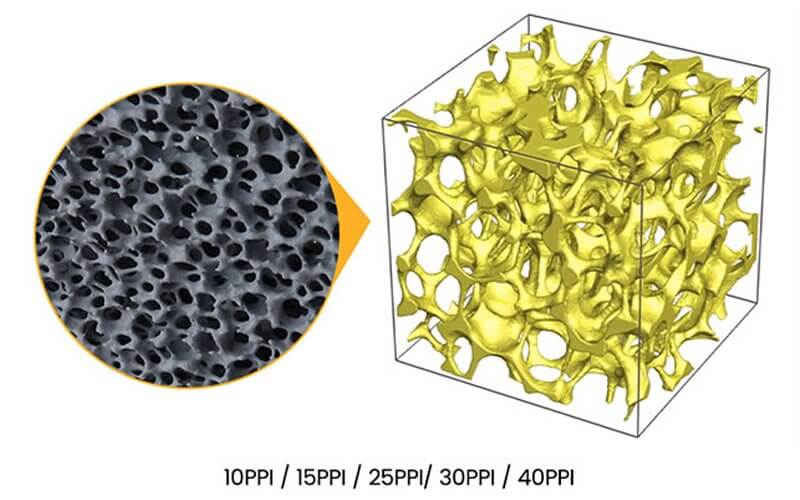

Pore Structure: Porous ceramic materials possess voids or interconnected pores within their structure, which contribute to their distinctive properties and functionality.

Porosity Levels: Porous ceramics exhibit a wide range of porosity levels, from low to high, depending on the application requirements.

B. Types of Porous Ceramic Materials:

Open-Cell Structure: Open-cell porous ceramics have interconnected pores, allowing for the free flow of fluids or gases through the material.

Closed-Cell Structure: Closed-cell porous ceramics have isolated pores that do not interconnect, making them impermeable to fluids or gases.

II. Enhanced Functionality of Porous Ceramic Materials:

A. Lightweight Construction:

Reduced Density: Porous ceramic materials exhibit lower density due to the presence of voids, enabling the production of lightweight components.

Weight Reduction: Lightweight ceramic structures offer advantages in industries such as aerospace, automotive, and transportation, where weight savings translate into improved fuel efficiency and enhanced performance.

B. Thermal Insulation:

Low Thermal Conductivity: Porous ceramics exhibit low thermal conductivity due to the presence of air or gas-filled pores, making them effective thermal insulators.

Energy Efficiency: Thermal insulation properties of porous ceramics contribute to energy savings by minimizing heat transfer in various applications, including building insulation and high-temperature processing.

C. Sound Absorption:

Acoustic Damping: The porosity of ceramic materials allows them to absorb and dissipate sound energy, reducing noise levels in various environments.

Noise Control: Porous ceramics find applications in soundproofing, automotive mufflers, and architectural acoustics, improving noise control and creating quieter environments.

D. Filtration and Separation:

Selective Permeability: Porous ceramic materials can be engineered with specific pore sizes and distributions, enabling precise filtration and separation of fluids or particles based on their size.

Applications: Porous ceramics are used in filtration systems, gas separation membranes, water treatment, and biomedical devices, providing efficient purification and separation capabilities.

III. Improved Performance and Durability:

A. Enhanced Mechanical Strength:

Structural Reinforcement: The presence of interconnected pores in porous ceramic materials can enhance their mechanical strength and toughness.

Load-Bearing Applications: Porous ceramics find applications in load-bearing components, such as structural supports, cutting tools, and wear-resistant parts, where increased strength and durability are crucial.

B. Controlled Porosity:

Tailored Porosity: The porosity of ceramics can be precisely controlled during manufacturing, allowing for customized materials with specific properties suited to desired applications.

Optimized Performance: Tailored porosity enables the adjustment of properties such as thermal conductivity, permeability, and surface area, optimizing performance in various industries.

C. Thermal Shock Resistance:

Improved Thermal Stability: The presence of pores in ceramic materials provides avenues for stress relief and accommodates thermal expansion, enhancing their resistance to thermal shock.

High-Temperature Applications: Porous ceramics are utilized in high-temperature environments, such as refractory linings, furnace components, and thermal barriers, where resistance to thermal shock is essential.

IV. Versatility and Applicability:

A. Chemical Resistance:

Inertness: Porous ceramic materials exhibit excellent chemical stability and resistance to corrosive substances, making them suitable for aggressive chemical environments.

Chemical Processing: Their resistance to chemical attack enables their use in applications such as chemical reactors, catalyst supports, and chemical filtration systems.

B. Biocompatibility:

Tissue Engineering: Porous ceramics find applications in biomedical and tissue engineering fields due to their biocompatibility, allowing for cell adhesion, nutrient transport, and tissue ingrowth.

Implants and Prosthetics: Porous ceramic materials are used in bone grafts, dental implants, and joint replacements, facilitating the integration and long-term stability of medical devices within the human body.

C. Controlled Release Systems:

Drug Delivery: Porous ceramics can be engineered to serve as carriers for controlled drug release, providing a controlled and sustained release of therapeutic agents.

Medical Applications: Their use in bone grafts, wound healing, and localized drug delivery systems offers opportunities for targeted treatments and improved patient outcomes.

D. Environmental Applications:

Catalyst Supports: Porous ceramic materials act as efficient catalyst supports, providing high surface area and accessibility for chemical reactions, enabling environmental remediation and pollution control.

Energy Storage: Porous ceramics find applications in energy storage devices, such as fuel cells and batteries, due to their high surface area, ion conductivity, and thermal stability.

V. Manufacturing and Design Considerations:

A. Fabrication Techniques:

Foam Replication: Replication techniques allow for the creation of porous ceramics with complex geometries and controlled pore structures.

Sol-Gel Method: The sol-gel process enables the synthesis of porous ceramics with tailored properties, offering flexibility in material composition and porosity.

B. Material Selection:

Ceramic Compositions: Different ceramic materials, such as alumina, zirconia, and silicon carbide, can be utilized to create porous ceramics with varying properties to suit specific application requirements.

Hybrid Composites: Incorporating other materials, such as polymers or metals, into porous ceramics can enhance their properties or introduce additional functionalities.

C. Optimization of Pore Structure:

Pore Size and Distribution: The optimization of pore size and distribution can be achieved through careful control of processing parameters, allowing for specific functionalities and performance enhancements.

Computational Modeling: Computational simulations aid in the design and optimization of pore structures, predicting properties such as permeability, thermal conductivity, and mechanical strength.

VI. Sustainability and Environmental Considerations:

A. Waste Reduction:

Efficient Material Usage: The porosity in ceramic materials allows for reduced material consumption, leading to minimized waste generation during manufacturing.

Eco-friendly Production: Porous ceramics can be manufactured using sustainable practices and raw materials, contributing to environmentally conscious manufacturing processes.

B. Energy Conservation:

Insulating Properties: Porous ceramic materials’ thermal insulation capabilities help conserve energy by reducing heat transfer, resulting in lower energy consumption in applications such as building insulation and industrial processes.

Energy-efficient Technologies: The use of porous ceramics in energy storage systems, fuel cells, and high-temperature applications contributes to the development of energy-efficient technologies.

C. Recycling and Reusability:

Material Reclamation: Porous ceramic materials can be recycled and reused in various applications, minimizing waste and reducing the demand for new raw materials.

Closed-loop Systems: The circular economy concept promotes the incorporation of recycled porous ceramics into new products, fostering sustainability and resource conservation.

D. Environmental Compatibility:

Low Carbon Footprint: Porous ceramic materials, particularly those manufactured using sustainable practices, have a lower environmental impact compared to alternative materials.

Non-Toxic Nature: Porous ceramics are inherently non-toxic, making them safe for human health and the environment, especially in applications such as water filtration and biomedical devices.

Conclusion:

The advantages of porous ceramic material have expanded the possibilities of ceramic applications across various industries. Lightweight construction, thermal insulation, sound absorption, filtration capabilities, and improved mechanical strength are just a few of the advantages that porous ceramics offer. Their versatility, biocompatibility, and resistance to high temperatures and chemical corrosion enable their use in a wide range of applications, from aerospace and automotive to healthcare and environmental sectors. Continued advancements in fabrication techniques, material selection, and pore structure optimization will further enhance the performance and applicability of porous ceramics, driving innovation and enabling the development of novel solutions for current and emerging challenges in diverse fields.