Zirconia Ceramic Foam Filters (ZCFF): Improving Steel Casting Processes

Zirconia Ceramic Foam Filters (ZCFF) play a pivotal role in enhancing the quality of steel castings across various alloys, including unalloyed, low alloyed, stainless, high-alloyed, as well as Nickel and Cobalt-based super-alloys. Their exceptional resistance to corrosion and attack from molten steel liquid makes them indispensable in steel casting applications. ZCFF effectively remove inclusions, reduce trapped gas from liquid metal, and provide laminar flow, resulting in significantly cleaner metal. This cleanliness translates to higher-quality castings, reduced scrap, and fewer inclusion defects.

Application Versatility: Addressing Diverse Steel Alloys

ZCFF are designed for use with all types of steel, offering comprehensive protection against non-metallic contaminant residues and sand grains from entering the mold cavity. Their versatility ensures that the stringent quality requirements of various steel alloys are met consistently. Whether it’s unalloyed steel or high-alloyed super-alloys, ZCFF provide reliable filtration and ensure the integrity of the casting process.

Effective Filtration Mechanism: Ensuring Clean and Defect-Free Castings

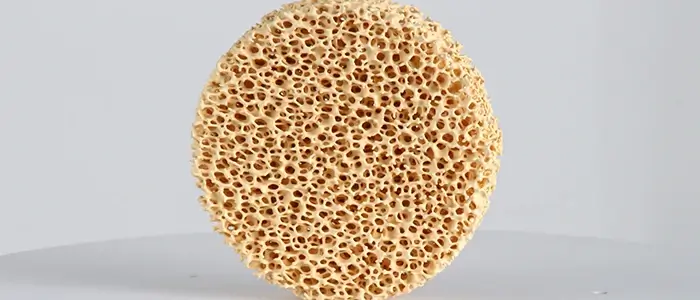

The characteristically large surface area of the reticulated foam in ZCFF facilitates intensive filtration, capturing even finely distributed slag and oxidation particles. These contaminants are retained both on the filter surface and within the filter structure, preventing them from compromising the quality of the casting. SEFU’s foam filters, known for their high filtration effectiveness, ensure that steel castings meet stringent quality standards while minimizing defects.

Reduced Turbulence: Enhancing Casting Efficiency

In addition to their filtration effectiveness, ZCFF contribute to reduced gating turbulence during the casting process. By promoting laminar flow and minimizing turbulence, these filters optimize metal flow dynamics within the mold cavity. This streamlined flow results in smoother casting surfaces, improved dimensional accuracy, and reduced rework requirements, ultimately enhancing casting efficiency and productivity.

Conclusion: Elevating Steel Casting Quality with Zirconia Ceramic Foam Filters

In conclusion, Zirconia Ceramic Foam Filters (ZCFF) stand as indispensable components in steel casting processes, offering unparalleled filtration efficiency and reliability across diverse steel alloys. Their ability to remove inclusions, reduce trapped gas, and provide laminar flow ensures cleaner metal and higher-quality castings with fewer defects. By incorporating ZCFF into steel casting operations, manufacturers can elevate their product quality, reduce scrap, and enhance overall process efficiency, thereby maintaining a competitive edge in the demanding steel industry.