At SF-Foundry, we stand at the forefront of the global foundry supply industry, not merely as a manufacturer, but as a dedicated solutions partner. With years of experience serving foundries across continents, we have built our reputation on a deep understanding of the intricate challenges in metal casting. Our mission is clear: to empower foundries worldwide to achieve zero-defect production by providing advanced, reliable consumables and expert technical support. We specialize in engineering the critical components that intervene at precise points in your casting process—from molten metal treatment to feeding and solidification control—transforming potential failure points into guarantees of quality and consistency.

The Foundry Challenge: A Proactive Approach to Casting Defects

In our daily collaboration with foundries, we see that defects are more than rejects; they are symptoms of process variables slipping out of optimal control. A reactive approach—inspecting defects out—is costly and inefficient. The modern, competitive foundry must be proactive, building quality into every step of the process. This begins with a fundamental understanding of defect genesis and is solidified by implementing robust, science-backed countermeasures. The most prevalent and critical defects typically stem from issues in shrinkage compensation and metal cleanliness, two areas where SF-Foundry’s core expertise delivers transformative results.

Conquering Shrinkage & Inclusion Defects

1. Shrinkage Defects: The Battle for Soundness

Shrinkage cavities and porosity occur because metals contract significantly as they transition from liquid to solid. If this volumetric loss is not continuously fed with liquid metal, internal voids form.

Root Causes & Identification:

- Inadequate Feeding: Risers (feeders) that are too small, incorrectly placed, or that solidify too early fail in their primary duty.

- Poor Solidification Direction: The casting must solidify progressively from the farthest points back toward the risers. Uncontrolled or isolated “hot spots” become defect zones.

- Identification: Shrinkage porosity appears as jagged, interconnected cavities, often in the thermal centers of thick sections or at junctions. A macroscopic shrinkage cavity is a large, obvious void in the last-to-solidify area.

The SF-Foundry Solution – Advanced Feeding Systems:

This is where our Feeding and Riser Sleeve Technology becomes indispensable. We don’t just supply standard products; we provide a systematic approach to feeding efficiency.

- Insulating Sleeves: Our sleeves dramatically reduce the heat loss from the riser, keeping the metal liquid 2-3 times longer than an uncovered riser. This provides a critical window for effective feeding.

- Exothermic Sleeves: For even more demanding applications, our exothermic sleeves generate their own heat, creating an ultra-hot feeder that ensures the final, critical stages of solidification are fed. This is often the key to soundness in heavy steel or iron castings.

- Expert Collaboration: From our experience, the correct sleeve choice (size, insulation rating, exothermic power) is dictated by the alloy, casting geometry, and molding process. We work with your team to model and select the optimal feeding system to eliminate shrinkage at the design stage.

2. Inclusion Defects: The Pursuit of Metal Purity

Inclusions—non-metallic particles like slag, oxides, and eroded sand—act as stress raisers, severely compromising mechanical properties and pressure tightness.

Root Causes & Identification:

- Oxide Formation: Exposure of molten metal (especially aluminum and ductile iron) to air during transfer and pouring generates oxide films.

- Slag Entrainment: Failure to properly trap and retain slag from the furnace or ladle before the metal enters the mold.

- Mold Erosion: High-velocity metal flow can scour sand from the mold or core walls.

- Identification: Inclusions appear as irregular, often dark, discontinuities on machined surfaces or in radiographs. They are distinctly different in structure from the surrounding metal matrix.

The SF-Foundry Solution – Precision Filtration Technology:

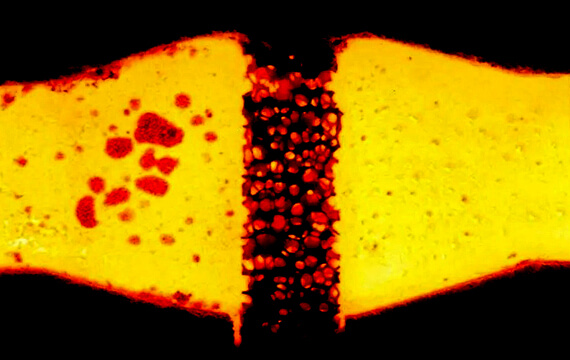

The most effective engineering method to capture inclusions is in-line filtration. Our flagship solution is our range of Customizable Ceramic Foam Filters (CFF).

- Engineered Filtration: We provide filters in various pore sizes (e.g., 10, 20, 30 PPI) and ceramic compositions (alumina, silicon carbide, zirconia) to match the specific alloy being cast and the size range of inclusions targeted. A coarse filter for heavy slag removal differs from a fine filter for capturing microscopic oxides.

- Beyond the Filter: Effective filtration requires a total system approach. We advise on the optimal filter placement, gating design to promote calm flow through the filter, and the use of our ceramic pouring cups and ladle liners to minimize re-oxidation after the filtration stage. This integrated system ensures clean metal fills the cavity.

Beyond the Big Two: Other Critical Defects and Holistic Control

While shrinkage and inclusions are paramount, a holistic quality strategy addresses other common failures.

-

Gas Porosity (Pinholes): Caused by hydrogen dissolved in the melt or gases from the mold. Prevention hinges on proper metal degassing (using our rotary degassers for non-ferrous metals) and ensuring mold/core dryness.

-

Cold Shuts & Misruns: Occur when metal fronts lose too much heat and fail to fuse. Prevention involves optimizing pouring temperature, improving gating for faster fill, and, for certain processes, using our mold heating solutions to control thermal profiles.

-

Hot Tears: Cracks formed during solidification due to restricted contraction. Prevention focuses on improving mold/core collapsibility and modifying casting design to reduce stress concentration—areas where our specialty coatings can aid.

The SF-Foundry Advantage: From Products to Partnership

Our commitment extends beyond delivering boxes of products. We offer a partnership based on shared success.

-

Defect Analysis Support: Share your defect challenges with us; our technical team can often help diagnose the root cause based on the defect’s morphology and location.

-

Process-Specific Solutions: Whether you operate in sand casting, investment casting, or gravity die casting, we have tailored product lines—from investment casting filters and crucibles to permanent mold coatings—designed for your environment.

-

Global Supply, Local Expertise: We ensure reliable, timely delivery of our consumables to keep your production line running smoothly, backed by accessible technical expertise.

Conclusion: Building Your Roadmap to Zero Defects

Eliminating casting defects is a systematic journey that integrates meticulous process design, precise parameter control, and the strategic application of high-performance consumables. By partnering with SF-Foundry, you gain more than a supplier; you gain an ally equipped with the tools and knowledge to fortify your process at its most vulnerable points.

Ready to transform your approach to quality control? Contact SF-Foundry today. Let our experts analyze your specific defect patterns and craft a targeted solution package—from custom-engineered ceramic foam filters to optimize metal cleanliness, to advanced feeder sleeve systems that guarantee sound solidification. Together, we can build a more robust, efficient, and profitable foundry operation.