Why Continuous Casting Dominates Modern Mills

In today’s steel industry, efficiency and consistency are not just goals—they are survival requirements. Having worked with mills globally, I’ve seen firsthand how Continuous Casting (Concaster) is the irreversible core that makes modern, cost-effective steel production possible. Unlike traditional batch methods, it transforms molten steel directly into a continuous solid strand in one seamless operation.

This isn’t just an incremental improvement; it’s a complete paradigm shift. The advantages are foundational to the business:

-

Unmatched Yield: It boosts material yield from liquid steel to finished product to over 96%, virtually eliminating the massive losses associated with ingot casting.

-

Radical Energy Savings: By consolidating multiple steps into one, it slashes energy consumption—a critical factor in today’s cost-conscious and environmentally regulated landscape.

-

Superior, Consistent Quality: Automated control enables unprecedented consistency in the chemical and physical properties of the strand from start to finish.

Simply put, if a mill aims for volume, quality, and profitability, continuous casting is the only path forward.

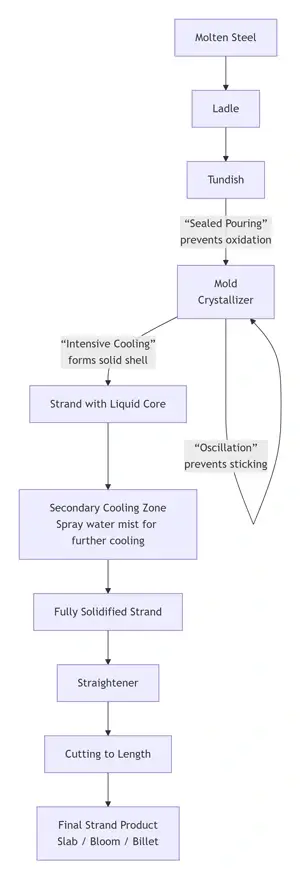

Continuous Casting Process: A Precise Journey from Liquid to Solid

The continuous caster is a marvel of thermo-mechanical engineering. To understand where quality is made or lost, let’s follow the steel’s journey through its key stages.

1. The Tundish: The Final Metallurgical Sanctuary

The tundish is far more than a passive distributor. From our perspective at SF-Foundry, it is the last critical checkpoint for steel cleanliness before solidification. Here, the flow is stabilized, and inclusions have a final chance to float out. Its internal architecture—guided by refractory dams and weirs we often help optimize—is crucial for creating a calm, controlled flow into the mold.

2. The Mold: Where the Surface is Born

This water-cooled copper mold is where the magic begins. The steel touches the cold wall and instantly forms a thin, solid shell. Two elements here are non-negotiable:

-

Mold Oscillation: Prevents the shell from sticking, a parameter that must be finely tuned.

-

Mold Powder: This consumable melts to form a protective slag layer that lubricates, controls heat transfer, and absorbs impurities. Its performance directly dictates surface quality.

3. Secondary Cooling & Support: Solidifying the Core

As the strand exits the mold with its fragile shell, it enters the secondary cooling zone. Here, a meticulously calculated spray of water completes the solidification process. Support rolls are essential to prevent the soft strand from bulging under the internal liquid pressure, which can lead to internal defects.

4. Cutting to Product: The Output

The fully solid strand is straightened (in curved mold casters) and cut into slabs, blooms, or billets—the primary products for all rolling mills.

The Inevitable Challenges: Where Defects Occur and Why

Despite its automation, the process is fraught with potential quality pitfalls. In our collaborations, we focus on helping mills tackle these critical issues:

| Defect Category | Common Types | Root Causes | Impact on Final Product |

|---|---|---|---|

| Surface Defects | Longitudinal cracks, transverse cracks, slag entrapment. | Unstable mold level, poor mold powder performance, uneven cooling. | Leads to extensive surface grinding, scrap, or failures in rolled products. |

| Internal Defects | Centreline segregation, internal cracks. | Incorrect secondary cooling, inadequate strand support, improper solidification ending point. | Compromises mechanical properties like strength and ductility, leading to potential part failure. |

| Cleanliness Issues | Macro-inclusions, micro-inclusion clusters. | Re-oxidation during transfer, erosion of refractories, carryover of ladle slag. | Catastrophic for high-grade steels (bearings, automotive), causing fatigue failure and poor machinability. |

The SF-Foundry Advantage: Integrated Solutions at Critical Points

We don’t just sell products; we provide targeted interventions based on a deep understanding of continuous casting metallurgy. Our materials act at specific points in the process to prevent the defects listed above.

1. Our Core Mission: Achieving Uncompromising Steel Cleanliness

This is where our expertise shines brightest. The Ceramic Foam Filter (CFF) is a game-changer for mills producing high-value steels.

-

How It Works: Installed in the tundish, our filters, such as advanced Zirconia-based filters, act as a final, deep-cleaning sieve. They physically capture microscopic inclusion clusters (especially harmful Al₂O3) that flotation alone cannot remove.

-

The Result from Our Experience: Mills using our filtration systems report a documented reduction in macro-inclusions and a significant improvement in the fatigue life and surface quality of their rolled products. It’s the most effective way to ensure the steel entering the mold is as pure as possible.

2. Ensuring Process Stability and Control

Precision requires reliable tools. We supply several essentials that keep the process stable:

-

Quick Thermocouples: Consistent, rapid, and accurate temperature measurements in the ladle and tundish are the bedrock of a stable casting operation. The right temperature prevents breakout and surface defects.

-

Tundish Pouring Cup (Starter Nozzle): This specialized cup ensures a safe, controlled, and automatic start of casting, eliminating the dangerous and inconsistent manual opening of the tundish nozzle, which can lead to initial slag entrapment.

3. Enabling Advanced Operations

For specialized applications like Upward Continuous Casting for copper alloys or precious metals, the requirements shift. Here, our dedicated casting crucibles and bespoke refractory shapes become central to the process’s success, providing the necessary thermal and chemical resistance.

The Future of Casting and Our Commitment

The evolution of continuous casting is geared towards higher speed, near-net-shape casting (thin slab, strip), and intelligent, data-driven control. These trends will place even greater demands on steel cleanliness and process stability.

At SF-Foundry, our innovation pipeline is aligned with this future. We are constantly developing next-generation filter materials with higher flow rates and capture efficiency, as well as more durable refractory solutions. Our goal is to remain the essential partner for mills that view liquid metal quality as the non-negotiable foundation of their competitive advantage.

Ready to push the limits of your continuous casting quality?

Partner with SF-Foundry. From advanced tundish filtration to the precise tools that ensure process stability, we provide the proven materials and the collaborative expertise to help you achieve zero-defect casting. Contact us today to discuss how our solutions can be integrated into your operation to secure your yield, quality, and profitability.