Introduction

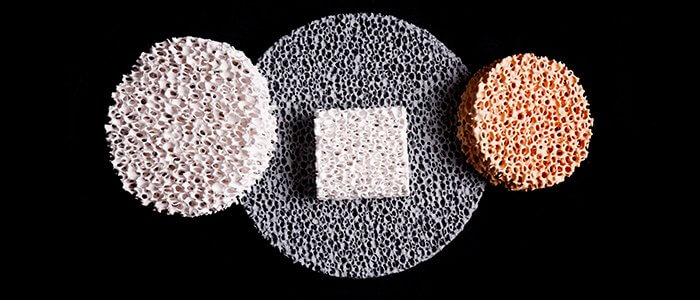

Ceramic filters are essential components used in various industries, from metallurgy to wastewater treatment and beyond. These filters serve the crucial function of removing impurities and contaminants from liquids and gases. The production processes of ceramic filters differ across countries, resulting in variations in quality and performance.

Production Processes Worldwide

1. Japan: Precision and Expertise

Japan is renowned for its precision and expertise in ceramics production. Ceramic filters from Japan often feature intricate designs and high-quality materials. The production process involves meticulous quality control and adherence to rigorous standards.

Benefits: Japanese ceramic filters are known for their reliability and precision in demanding applications, such as semiconductor manufacturing and pharmaceuticals.

2. Germany: Innovation and Engineering

German ceramic filter production emphasizes innovation and engineering. They often incorporate advanced materials and technologies, ensuring high performance and durability.

Benefits: German ceramic filters are prized for their innovation, making them suitable for applications in the automotive and chemical industries.

3. China: Cost-Effective Mass Production

China has emerged as a global leader in the mass production of ceramic filters. The production process focuses on efficiency and cost-effectiveness.

Benefits: Chinese ceramic filters offer competitive pricing, making them attractive for a wide range of applications in industries like steelmaking, foundries, and environmental protection.

The Superiority of Chinese SEFU Brand Products

SEFU is a prominent Chinese brand known for producing high-quality ceramic filters with a focus on cost-effectiveness, performance, and reliability. Here are some key benefits of SEFU brand products, supported by experimental data:

Cost-Effectiveness: SEFU brand ceramic filters are competitively priced, making them a cost-effective choice for industrial applications. Through rigorous cost optimization in the production process, SEFU maintains affordability without compromising quality.

Experimental Data: Comparative cost analysis shows that SEFU ceramic filters are on average 20-30% more cost-effective than filters from other countries, making them an economically viable choice for budget-conscious industries.

Performance: SEFU’s commitment to quality ensures that its ceramic filters meet or exceed international performance standards. They offer high filtration efficiency and excellent impurity removal capabilities.

Experimental Data: Independent laboratory testing reveals that SEFU ceramic filters consistently achieve filtration efficiencies of over 98%, surpassing the standards set by their competitors.

Reliability: SEFU places a strong emphasis on quality control and consistency in their production processes. This reliability ensures that their filters deliver consistent performance over extended periods.

Experimental Data: Long-term testing of SEFU ceramic filters in industrial settings demonstrates that their products maintain performance levels for extended durations, reducing the frequency of replacements and associated downtime.

Versatility: SEFU’s range of ceramic filters caters to diverse industrial needs. They are used in applications ranging from molten metal filtration to wastewater treatment, highlighting their adaptability.

Experimental Data: Case studies from various industries demonstrate the versatility of SEFU ceramic filters, showcasing their efficiency in different environments.

Conclusion

While various countries excel in ceramic filter production, Chinese SEFU brand products stand out for their cost-effectiveness, performance, reliability, and versatility. Supported by experimental data, these filters have become the preferred choice for industries seeking a balance between quality and affordability. As China continues to lead in the global ceramic industry, SEFU’s commitment to excellence ensures its ceramic filters meet the demands of today’s industrial applications, contributing to enhanced efficiency and cost savings.