During the aluminum liquid filtration process, common problems such as blockage and poor filtration efficiency will affect production efficiency and product quality. The following will introduce solutions to these common problems and methods to improve the filtration efficiency of aluminum liquid.

Common Problems and Solutions in Aluminum Liquid Filtration:

Blockage problem:

Solution: Clean the filter regularly to avoid large particles of impurities blocking the pores; adjust the filtration frequency to avoid clogging caused by long-term operation of the filter.

Poor filtration efficiency:

Solution: Make sure to select a suitable alumina ceramic foam filter, adjust the filter type and specifications according to the aluminum water quality and process requirements; check the filter status regularly, and replace or clean the filter in time.

Filter damage problem:

Solution: Control the aluminum liquid temperature to avoid damage to the filter due to excessive temperature; select a reliable filter brand and supplier to ensure stable filter performance.

Improper filtration frequency:

Solution: Adjust the filtration frequency according to production needs and aluminum water quality to avoid a filtration frequency that is too low or too high.

Methods to Improve the Filtration Efficiency of Aluminum Liquid:

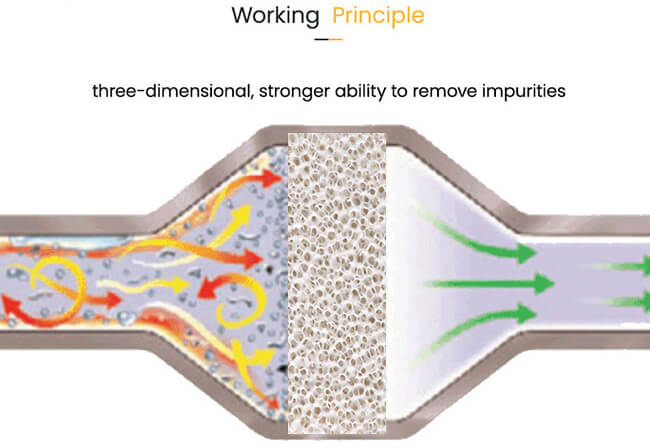

- Choose a suitable filter: Choose a suitable alumina ceramic foam filter according to the aluminum water quality and production needs to ensure filtration effect and permeability.

- Regular maintenance and cleaning: Clean the filter regularly to ensure that the filter channels are unobstructed and avoid blockage; replace damaged filters in time.

- Optimize the filtration process: Adjust the filter usage and filtration frequency, optimize the filtration process parameters, and improve the filtration efficiency.

- Control the quality of molten aluminum: Optimize the molten aluminum smelting process, reduce the generation of inclusions and bubbles, improve the quality of molten aluminum, and help improve filtration efficiency.

By solving common problems and taking measures to improve filtration efficiency, the efficiency and quality of molten aluminum filtration can be effectively improved to ensure the smooth production of aluminum products. Regular maintenance of filtration equipment, optimization of filtration processes, and control of molten aluminum quality are key steps to improve filtration efficiency, which helps to improve production efficiency and product quality.