Ceramic Foam Filters for High-Temperature Molten Metal Filtration

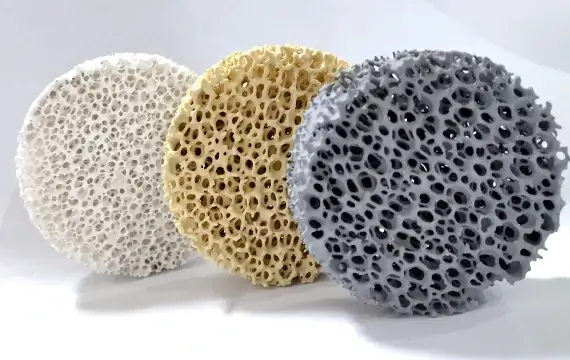

SEFU CERAMIC offers a wide range of ceramic foam filters for high-temperature molten metal filtration applications. These porous materials with interconnected pore networks are suitable for high-temperature environments and can effectively remove impurities from liquid metal.

- High porosity

- Large specific surface area

- Thermal shock resistance

- High temperature resistance

- Chemical resistance

- Good mechanical strength

- Good filtration and adsorption performance

- SEFU CERAMIC FOAM

- What Does PPI Stand For In Filter?

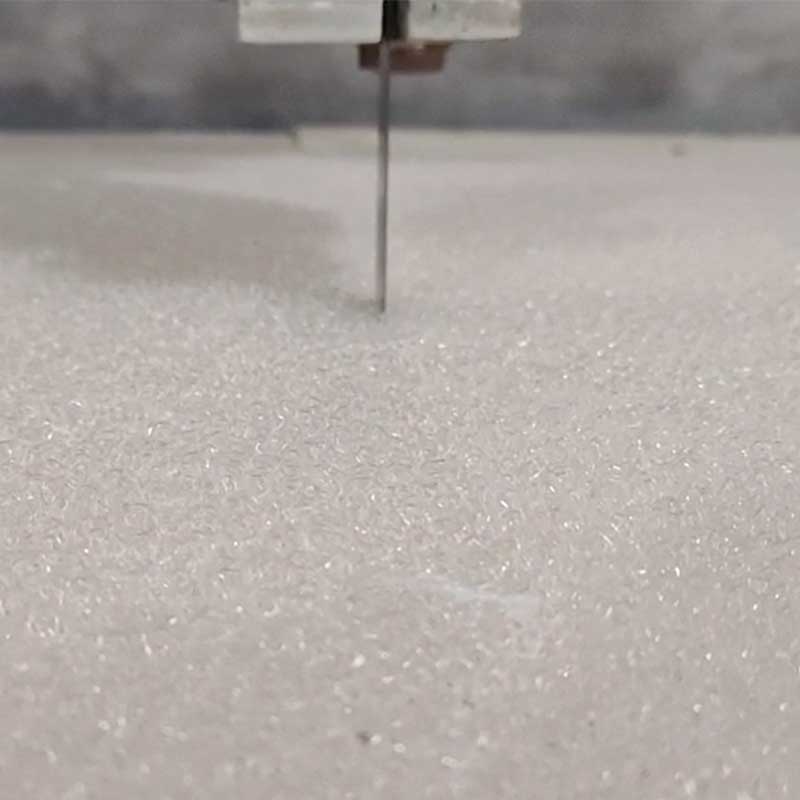

- Production of SEFU Ceramic Filters

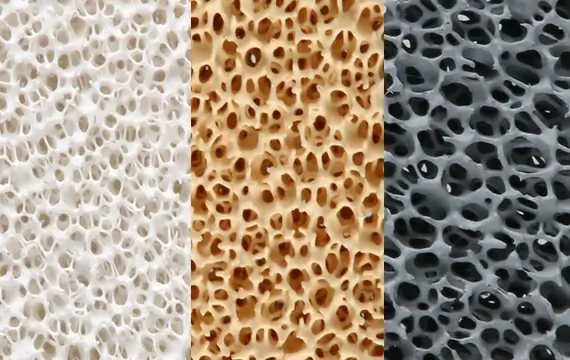

| Type | Name | Application | Maximum working temperature (℃) |

| SCF | Silicon carbide ceramic foam filter | Iron cast industry | 1500 |

| ACF | Alumina ceramic foam filter | Aluminum and aluminum alloy industry | 1100 |

| ZCF | Zirconia ceramic foam filter | Steel cast industry | 1700 |

PPI is a relatively unique representation of ceramic foam. It refers to the pores per inch. The following is the specific SEFU CERAMIC foam PPI meaning.

| Types | Pore density (Number of holes/25.4㎜) |

| 10PPI | 7-12 |

| 15PPI | 13-17 |

| 20PPI | 18-22 |

| 25PPI | 23-27 |

| 30PPI | 28-32 |

| 35PPI | 33-37 |

| 40PPI | 38-43 |

Types and Applications of Ceramic Foam

SEFU CERAMIC casting filters are available in different materials such as Al2O3, ZrO2, SiC, and MgO, each with a different working temperature range.

- Al2O3 ceramic foam filters can withstand temperatures up to 1000℃, making them ideal for filtering aluminum and aluminum alloys.

- ZrO2 filters have a working temperature of up to 1700℃ and are ideal for filtering stainless steel, carbon steel, and large cast iron alloys.

- SiC filters have a temperature limit of 1500℃ and are perfect for filtering liquid metal in iron, gray iron, and non-ferrous alloys.

- MgO filters offer excellent resistance to chemical corrosion and thermal shock and are ideal for filtering magnesium and its alloys.

Features of Ceramic Foam

SEFU ceramic foam filters have a high porosity and a large specific surface area, which helps to increase the filtration capacity. They also exhibit excellent mechanical strength and stability under high-temperature environments, ensuring a long service life. Our ceramic filters possess excellent filtering and absorption properties and can effectively remove impurities to enhance the quality of the final product.

What Is Ceramic Foam Used For?

SEFU CERAMIC ceramic foam filters are widely used in the metallurgical industry for filtering molten metal in the production of cast iron, cast aluminum, cast steel, and other metal alloys. They are an important tool for improving the mechanical properties and final quality of the products.

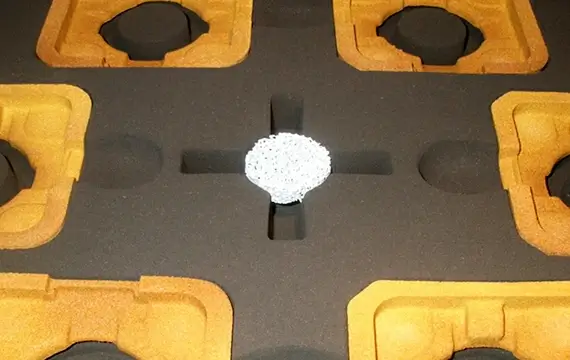

SEFU Ceramic filters come in a variety of shapes and sizes to meet different industrial requirements, such as foundries, die casting, investment casting, and continuous casting processes.

Customize Your Ceramic Foam Now

SEFU CERAMIC ceramic foam filters offer an excellent solution for the effective filtration of liquid metal in high-temperature environments. Their unique properties make them ideal for use in the metallurgical industry and other industrial applications. With SEFU CERAMIC filters, you can ensure a high-quality final product and improve the efficiency and productivity of your operations.

For more information, don’t hesitate to get in touch with SEFU CERAMIC today.

Contact us now and let SEFU CERAMIC’s experienced experts customize and supply more suitable casting materials for you.