Introduction:

Ceramic foam filters have emerged as indispensable tools in the metal casting industry, revolutionizing the way molten metals are filtered and purified. Their unique open-cell foam structure, typically composed of silicon carbide (SiC) material, provides a large surface area for efficient filtration of impurities. This article delves into the significance of ceramic foam filters for casting, their working principles, and the advantages they offer to foundries and manufacturers.

I. The Importance of Filtration in Metal Casting:

Metal casting is a complex process that involves transforming molten metal into intricate shapes and forms. During casting, molten metal is susceptible to contamination from various impurities, such as oxides, slag, and non-metallic inclusions. The presence of these impurities can lead to casting defects, reduced mechanical properties, and decreased overall product quality.

Filtration plays a critical role in the metal casting process, as it helps remove these unwanted impurities, ensuring the production of clean and defect-free castings. Traditionally, filters made from materials like sand, ceramic, or metal meshes were used for this purpose. However, ceramic foam filters have gained prominence due to their superior performance and efficiency.

II. Understanding Ceramic Foam Filters:

Ceramic foam filters are unique filtering devices with a highly porous and interconnected structure, resembling sponge-like foam. The most common material used for these filters is silicon carbide (SiC), renowned for its high thermal stability, mechanical strength, and chemical resistance. Other materials like alumina and zirconia are also used, depending on specific casting requirements.

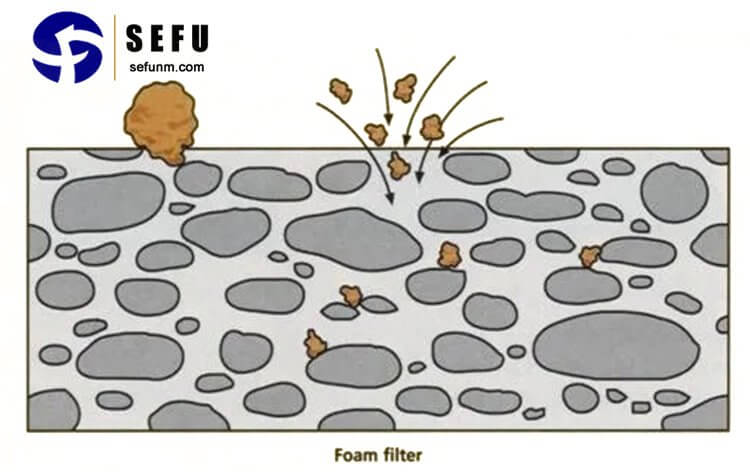

The open-cell foam structure of ceramic filters allows molten metal to pass through the interconnected pores, while efficiently trapping and removing impurities present in the metal. This innovative design provides a larger filtration surface area compared to traditional filters, resulting in improved filtration efficiency and metal quality.

III. Working Principles of Ceramic Foam Filters:

The efficiency of ceramic foam filters lies in their ability to capture and retain impurities while allowing molten metal to flow through. The working principles of ceramic foam filters involve the following key steps:

Filtration Zone:

When molten metal is poured into the casting mold, it comes into contact with the ceramic foam filter placed within the gating system. As the metal passes through the filter’s porous structure, impurities are trapped and immobilized within the pores.

Physical and Chemical Filtration:

Ceramic foam filters employ both physical and chemical filtration mechanisms. The porous structure physically traps larger impurities like slag and oxides, while the chemical properties of the ceramic material interact with certain impurities, further improving the filtration process.

Purification of Molten Metal:

As the molten metal flows through the filter, it undergoes purification, with impurities getting captured and retained by the filter. This results in cleaner molten metal, ready to be cast into the desired shapes.

IV. Advantages of Ceramic Foam Filters for Casting:

Ceramic foam filters offer numerous advantages that make them a preferred choice in metal casting processes:

Enhanced Filtration Efficiency:

The open-cell foam structure of ceramic filters provides a significantly larger surface area for filtration compared to traditional filters. This increased surface area improves the filter’s ability to trap impurities, leading to enhanced filtration efficiency.

Improved Casting Quality:

By effectively removing impurities, ceramic foam filters contribute to producing high-quality castings with improved mechanical properties. This, in turn, reduces casting defects and rejections, resulting in cost savings for manufacturers.

Thermal Stability:

Ceramic foam filters made from materials like silicon carbide exhibit high thermal stability, allowing them to withstand the extreme temperatures of molten metals without deformation or structural damage.

Customization Options:

Manufacturers can choose from a wide range of filter shapes, pore sizes, and material compositions to tailor the filters according to their specific casting needs. This customization ensures optimal filtration performance for different casting processes and metal types.

V. Applications of Ceramic Foam Filters in Casting:

Ceramic foam filters find applications in a wide range of casting processes for both ferrous and non-ferrous metals. Some of the key casting applications where these filters are used include:

Steel Casting:

In the steel industry, ceramic foam filters play a crucial role in improving the quality of steel castings. They help remove impurities such as inclusions, oxides, and slag, resulting in steel products with enhanced mechanical properties and reduced defects.

Aluminum Casting:

Aluminum casting processes, including gravity casting, low-pressure casting, and sand casting, benefit significantly from ceramic foam filters. These filters aid in reducing hydrogen gas and inclusions, ensuring the production of high-quality aluminum components used in various industries.

Iron Casting:

In iron casting applications, ceramic foam filters effectively remove impurities like sand and slag, leading to improved surface finish and dimensional accuracy in the final castings.

Copper and Copper Alloy Casting:

Ceramic foam filters are extensively used in copper and copper alloy casting to remove impurities and control the grain structure, resulting in high-quality castings with excellent mechanical properties.

Investment Casting:

Investment casting, also known as lost wax casting, requires precise and intricate castings. Ceramic foam filters with their uniform flow distribution and fine filtration capability are ideal for investment casting applications, ensuring the production of complex castings with minimal defects.

VI. Ongoing Research and Advancements:

As technology and materials science continues to advance, researchers and manufacturers are continually exploring ways to enhance the performance and capabilities of ceramic foam filters. Some ongoing research and advancements include:

Nanotechnology in Filtration:

Incorporating nanotechnology into ceramic foam filters holds the promise of further improving filtration efficiency. Nanomaterials can enhance the chemical and physical interactions with impurities, making the filters even more effective in capturing smaller particles and improving casting quality.

Novel Material Compositions:

Beyond silicon carbide, researchers are exploring other advanced materials with unique properties for ceramic foam filters. This includes alumina, zirconia, and various composite materials that may offer specific advantages in particular casting applications.

3D Printing of Filters:

Additive manufacturing, particularly 3D printing, offers the potential to fabricate complex and custom-designed ceramic foam filters with intricate geometries. 3D printing can enable rapid prototyping and optimization of filter designs for specific casting processes, leading to better filtration efficiency.

Integration with Industry 4.0:

The concept of Industry 4.0, involving the integration of automation, data exchange, and smart manufacturing, can be applied to the casting industry. By incorporating sensors and data analytics, manufacturers can monitor and optimize the performance of ceramic foam filters, ensuring consistent and efficient filtration during casting processes.

VII. Future Prospects:

The future prospects of ceramic foam filters in the casting industry are promising. As the demand for high-quality castings increases, manufacturers will continue to seek advanced filtration solutions to meet stringent quality standards. Ceramic foam filters are well-positioned to address these demands with their proven advantages in enhancing metal quality, reducing defects, and optimizing casting processes.

Moreover, the ongoing research in material science and filter design is expected to unlock new possibilities for ceramic foam filters, enabling improved filtration performance and application in a broader range of casting processes. With the advent of Industry 4.0 and the integration of smart manufacturing technologies, ceramic foam filters will likely become an integral part of advanced casting systems, ensuring precision, efficiency, and sustainability in the metal casting industry.

Conclusion:

Ceramic foam filters have transformed metal casting processes by providing efficient and effective filtration of molten metals. With their unique open-cell foam structure, these filters offer enhanced filtration efficiency, improved casting quality, and reduced defects in a wider range of casting applications. As research and technology continue to progress, ceramic foam filters are poised to remain at the forefront of casting advancements, contributing to the production of high-quality castings in diverse industries. The relentless pursuit of innovation and customization in ceramic foam filter technology will continue to shape the future of metal casting, fostering efficiency, sustainability, and excellence in the manufacturing of complex and precise cast metal components.