Introduction:

In the realm of metal casting, achieving high-quality, defect-free components is of paramount importance. Whether in the aerospace, automotive, or manufacturing industries, the integrity of the cast metal plays a crucial role in determining the final product’s performance and longevity. One essential tool that aids in this process is the ceramic foam filter, a specialized component designed to improve the quality of molten metal by effectively removing impurities. In this article, we will delve into what ceramic foam filters are, how they work, their applications, and the benefits they bring to metal casting processes.

Understanding Ceramic Foam Filters

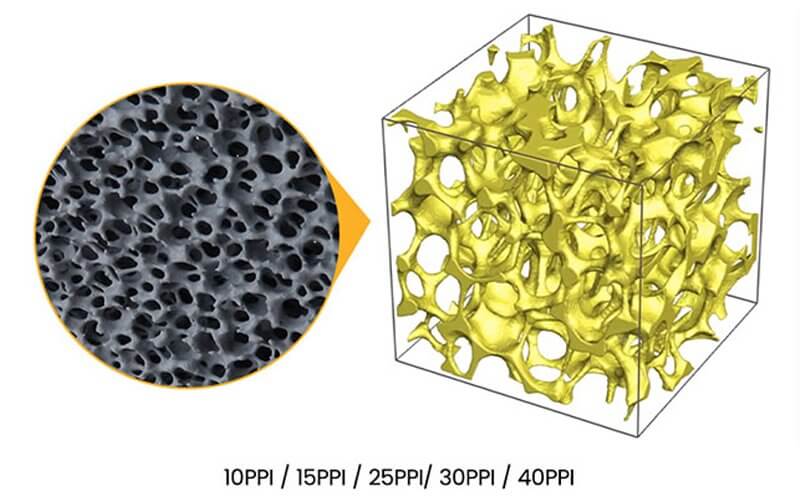

Ceramic foam filters are intricate, highly porous structures made from various ceramic materials, such as silicon carbide (SiC), alumina (Al2O3), or zirconia (ZrO2). These filters exhibit a three-dimensional network of interconnected pores, resulting in a sponge-like appearance. The intricate pore structure gives ceramic foam filters their unique ability to capture and remove impurities from molten metals during the casting process.

The Working Mechanism

The operation of ceramic foam filters revolves around the principles of filtration, adsorption, and capillarity. When molten metal is poured into a mold, it often contains unwanted impurities, such as oxides, slag, and non-metallic particles. These impurities can degrade the mechanical properties and surface finish of the final cast product. Ceramic foam filters come into play to address these issues.

Filtration:

The porous structure of the ceramic foam filter acts as a physical barrier. As the molten metal flows through the filter, impurities that are larger than the pore size get trapped within the filter’s interconnected pores. This prevents these contaminants from passing through and being incorporated into the final casting.

Adsorption:

Ceramic materials used in these filters have a natural affinity to adsorb certain impurities. This means that even impurities that are smaller than the pore size can be captured on the surface of the ceramic material. This adsorption process further improves the overall efficiency of the filter in removing unwanted substances.

Capillarity:

The capillary action in the porous structure of the ceramic foam filter assists in drawing the molten metal into the filter. This ensures even distribution of the metal within the mold and helps in the removal of air bubbles that might be present in the molten metal. Eliminating these bubbles contributes to a smoother surface finish in the final cast product.

Applications in Metal Casting Processes

Ceramic foam filters find widespread use in a variety of metal casting processes, including but not limited to:

Aluminum Casting:

In the production of aluminum components, ensuring a clean and defect-free final product is critical. Ceramic foam filters aid in removing oxides, inclusions, and other impurities, leading to improved mechanical properties and surface finish.

Steel Casting:

Steel, due to its high melting point, often encounters issues with impurities. Ceramic foam filters help in the removal of non-metallic inclusions, which can cause weaknesses in the cast steel.

Iron Casting:

Cast iron components used in automotive and industrial applications benefit from the use of ceramic foam filters. These filters aid in reducing sand inclusions and promoting a uniform distribution of the molten iron.

Investment Casting:

In this precision casting process, ceramic foam filters play a pivotal role in maintaining the quality of intricate and detailed components, such as turbine blades and aerospace components.

Benefits of Ceramic Foam Filters in Metal Casting Processes

The implementation of ceramic foam filters in metal casting processes offers numerous advantages:

Enhanced Quality: The removal of impurities leads to cast products with improved mechanical properties, better surface finish, and reduced defects.

Increased Efficiency: The combination of filtration, adsorption, and capillarity ensures efficient purification of the molten metal, reducing the need for secondary refining processes.

Consistency: Ceramic foam filters provide a consistent and reliable method for impurity removal, contributing to consistent product quality over time.

Reduced Scrap: By preventing the incorporation of impurities into cast products, ceramic foam filters help minimize the rejection rate and waste, leading to cost savings.

Sustainability: Improved casting quality and reduced waste align with sustainable manufacturing practices, making ceramic foam filters an environmentally friendly option.

Challenges and Considerations

While ceramic foam filters offer numerous benefits, they also come with certain challenges and considerations:

Pore Size Selection: The appropriate choice of pore size is crucial as it determines the size of impurities that can be effectively filtered. Different casting processes and metals might require different pore sizes.

Thermal Shock: The extreme temperature changes experienced during the casting process can subject the filters to thermal shock. Proper handling and preheating of the filters are necessary to avoid damage.

Cost: Ceramic foam filters can be more expensive than traditional filtration methods. However, the cost savings from improved product quality and reduced scrap can often outweigh the initial investment.

Manufacturing of Ceramic Foam Filters

The manufacturing process of ceramic foam filters involves several stages, each contributing to the final product’s quality and performance.

Material Selection: The choice of ceramic material depends on factors such as the type of metal being cast, the casting temperature, and the specific impurities to be removed. Silicon carbide (SiC), alumina (Al2O3), and zirconia (ZrO2) are popular choices due to their high-temperature stability and chemical resistance.

Pore Structure Design: The design of the porous structure is crucial as it determines the filter’s filtration efficiency and capacity. Manufacturers carefully engineer the size, distribution, and connectivity of the pores to optimize impurity removal while maintaining adequate flow rates.

Foaming Process: The ceramic material is mixed with a foaming agent and a binder. The mixture is then shaped into the desired filter shape and fired in a kiln. During firing, the foaming agent decomposes, creating pores in the material, while the binder solidifies, maintaining the filter’s structure.

Sintering and Heat Treatment: After foaming, the filters undergo sintering and heat treatment processes to further strengthen the ceramic structure and ensure thermal stability at high casting temperatures.

Customization and Advancements

Recent advancements in manufacturing technology have enabled the customization of ceramic foam filters to suit specific casting requirements. Here are a few notable developments:

Tailored Pore Size: Manufacturers can now produce filters with precise and consistent pore sizes, allowing for customization based on the size of impurities in different metal alloys.

Shaping and Sizing: Filters can be manufactured in various shapes and sizes to fit specific casting molds and configurations, providing enhanced flexibility to the casting process.

Multi-Layer Filters: Some applications benefit from multi-layer filters, where layers of different pore sizes are stacked. This approach allows for more efficient removal of a broader range of impurities.

High-Temperature Stability: Advancements in material science have led to the development of ceramic materials with improved high-temperature stability, enabling the use of ceramic foam filters in even more demanding casting processes.

Automated Handling: Automation has streamlined the handling and placement of ceramic foam filters within casting molds, reducing the risk of damage and improving consistency.

Future Prospects

As the metal casting industry continues to evolve, ceramic foam filters are likely to play a crucial role in achieving higher levels of quality and efficiency. Future prospects for ceramic foam filters include:

Nanotechnology Integration: Incorporating nanomaterials into ceramic foam filters could lead to improved adsorption capabilities, enabling the removal of even smaller impurities.

Digital Manufacturing: The integration of digital manufacturing techniques, such as 3D printing, could revolutionize the production of ceramic foam filters, allowing for intricate designs and rapid prototyping.

Data-Driven Optimization: The collection and analysis of data during casting processes could lead to optimized filter designs and casting parameters for specific alloys.

Hybrid Solutions: Combining ceramic foam filters with other filtration methods or additives could create hybrid solutions that address a broader range of impurities and casting challenges.

Conclusion:

Ceramic foam filters have proven to be indispensable tools in modern metal casting processes, revolutionizing the way impurities are removed from molten metals. Their intricate porous structure, combined with the principles of filtration, adsorption, and capillarity, ensures the production of high-quality cast products with enhanced mechanical properties and surface finish. While challenges such as pore size selection and thermal shock management exist, the benefits of improved efficiency, reduced scrap, and sustainable manufacturing make ceramic foam filters a compelling choice for various industries.

With ongoing advancements in material science, manufacturing techniques, and customization options, the future holds promising prospects for further enhancing the capabilities of ceramic foam filters in the world of metal casting.