Introduction

In the realm of metallurgy and manufacturing, the quality of final products often hinges on the purity of the materials used and the efficiency of the production process. One crucial tool that plays a significant role in achieving these goals is the ceramic foam filter. This unassuming yet indispensable component is responsible for refining molten metals during the casting process. In this article, we delve into the intricate details of foam filters, exploring their composition, functioning, applications, benefits, and even providing insights into their classification under the HSN code system.

Composition and Structure

Ceramic foam filters are intricate structures composed of open-cell ceramic materials. These materials are often based on oxides like alumina, silicon carbide, zirconia, and other specialized compositions tailored to withstand the extreme conditions of the metal casting process. The porous structure of the foam filter is designed to trap and remove impurities present in molten metals, ensuring the final product meets stringent quality standards.

The foam structure itself can have various pore sizes and configurations, allowing for customization based on the specific casting requirements. The interconnected pores create a labyrinthine pathway for the molten metal to flow through, facilitating efficient filtration while maintaining optimal flow rates.

Functioning and Applications of Ceramic Foam Filter

The primary function of a ceramic foam filter is to remove unwanted impurities from molten metals before they solidify into the final casting. During the casting process, various contaminants such as oxides, slag, and non-metallic inclusions can adversely affect the mechanical properties and overall quality of the end product. The ceramic filter acts as a barrier, capturing these impurities and allowing only clean molten metal to pass through.

Ceramic filters find applications in a wide range of metal casting processes, including but not limited to:

Foundries:

In the foundry industry, ceramic foam filters are used in the casting of metals like aluminum, steel, iron, and copper-based alloys. They help eliminate defects like porosity, inclusions, and gas-related issues in the final castings.

Investment Casting:

Also known as the “lost-wax” process, investment casting requires high precision and impeccable surface finish. Ceramic filters aid in achieving these characteristics by removing fine particles and ensuring a smooth flow of molten metal into intricate molds.

Continuous Casting:

In continuous casting operations, ceramic filters help control the flow of molten metal, preventing the buildup of impurities that can lead to clogging of equipment or compromised product quality.

Aerospace and Automotive Industries:

Both industries demand precise and high-strength components. Ceramic foam filters contribute to achieving these standards by enhancing the quality of castings used in critical applications.

![]()

Benefits of Ceramic Foam Filter

The use of ceramic foam filters offers several significant benefits that positively impact the casting process and the final product:

Improved Quality:

By removing impurities, ceramic filters help produce castings with fewer defects, higher mechanical properties, and enhanced surface finish.

Enhanced Efficiency:

The porous structure of the filters ensures efficient filtration without significantly impeding the flow of molten metal, thereby maintaining production efficiency.

Cost Savings:

Reduced defects and improved quality mean less post-casting rework or rejection, translating to cost savings in terms of material and labor.

Versatility:

Ceramic foam filters can be tailored to suit various casting processes and metal alloys, making them a versatile solution for a wide range of applications.

Environmental Impact:

Cleaner metal casting processes result in reduced waste generation and lower energy consumption, contributing to a more sustainable manufacturing ecosystem.

Ceramic Foam Filter HSN Code Classification

The Harmonized System of Nomenclature (HSN) code is a standardized classification system used globally to classify traded products. Ceramic foam filters fall under the category of refractory ceramic goods, and their HSN code generally ranges from 6909.12 to 6909.19, depending on the specific composition and use.

6909.12: Ceramic filters with a base of alumina (aluminum oxide).

6909.19: Other ceramic filters, including those with bases of silicon carbide, zirconia, or other materials.

It’s important to note that HSN codes may vary slightly based on regional or national modifications to the system. Importers, exporters, and manufacturers should refer to the latest HSN code listings provided by their respective customs authorities to ensure accurate classification and adherence to regulations.

Evolution and Advancements

The concept of using filters in metal casting dates back several decades, but it was the evolution of ceramic foam filters that brought about significant advancements in the field. Traditional filters, often made from sand or ceramic grains, had limitations in terms of their efficiency and effectiveness in removing fine impurities. Ceramic filters revolutionized the process by providing a larger surface area for filtration within a three-dimensional porous structure. This innovation led to cleaner castings and improved mechanical properties, driving the demand for these filters across industries.

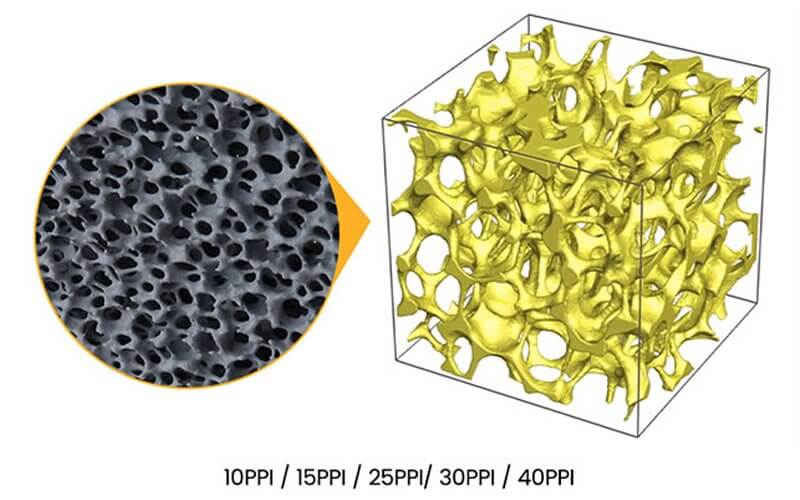

Pore Size and Configuration

The design of ceramic foam filters involves careful consideration of pore size and configuration. Pore size plays a critical role in determining the types of impurities that can be captured. Larger pores may effectively remove larger particles but could allow smaller impurities to pass through. Conversely, smaller pores can capture finer impurities but might lead to clogging issues if not managed properly. Manufacturers customize the pore size and configuration of filters based on the specific characteristics of the molten metal and the desired quality of the final casting.

Installation and Placement

The proper installation and placement of ceramic foam filters within casting systems are crucial for achieving optimal results. Filters are strategically positioned at various points within the casting process to ensure that molten metal passes through them before entering the mold. The placement depends on factors such as the flow dynamics of the metal, the geometry of the mold, and the specific casting requirements. Careful consideration of these factors ensures that the filters effectively trap impurities without causing disruptions to the casting process.

Quality Control and Testing

The use of ceramic foam filters aligns with the industry’s pursuit of higher quality standards. However, ensuring the effectiveness of these filters involves rigorous quality control measures. Manufacturers and foundries conduct testing to verify the filtration efficiency of the filters, including assessing their ability to remove specific impurities. Additionally, the mechanical strength of the filters is evaluated to ensure they withstand the pressures and temperatures of the casting process without disintegrating or deforming. These quality control measures are vital to maintaining consistency in the quality of castings.

Innovations and Future Trends

As technology continues to advance, so do the capabilities of ceramic foam filters. Researchers and manufacturers are exploring ways to enhance their performance through improved materials, innovative designs, and optimized production processes. Some areas of innovation include:

Nanotechnology:

Incorporating nanomaterials into ceramic foam filters can enhance their filtration efficiency by enabling the capture of even smaller impurities.

3D Printing:

Additive manufacturing techniques are being applied to create complex and customized filter designs that can improve filtration effectiveness in specific casting scenarios.

Multi-Layer Filters:

Combining different types of ceramic foam layers with varying porosity can offer enhanced filtration capabilities for a broader range of impurities.

Smart Sensors:

Integration of sensors within filters could provide real-time data on filtration efficiency, allowing for proactive adjustments in the casting process.

Conclusion

Ceramic foam filters have truly transformed the landscape of metal casting, enabling industries to achieve higher standards of quality and efficiency. Their intricate structure, composition, and strategic placement within casting systems contribute to the production of castings with improved mechanical properties and reduced defects. As research and development in materials science and manufacturing techniques continue to evolve, we can expect to witness further innovations in foam filters, solidifying their role as essential components in the pursuit of excellence in metal casting processes.