During the metal casting process, impurities in the molten metal (such as oxides, slag inclusions, bubbles, etc.) will directly affect the mechanical properties and surface quality of the castings. In order to effectively remove these impurities, the foundry industry widely adopts filtration technology, among which the Cap-Shaped Fiberglass Mesh Filters for Casting has become an important choice for casting aluminum alloys, magnesium alloys, etc. due to its low cost, convenient use, and stable filtration effect.

This article will introduce in detail the material properties, working principles, application scenarios, usage methods and industry development trends of the Cap-Shaped Fiberglass Mesh Filters, to help casting engineers, purchasers and manufacturers to select the product more scientifically, optimize the casting process, and improve the quality of castings.

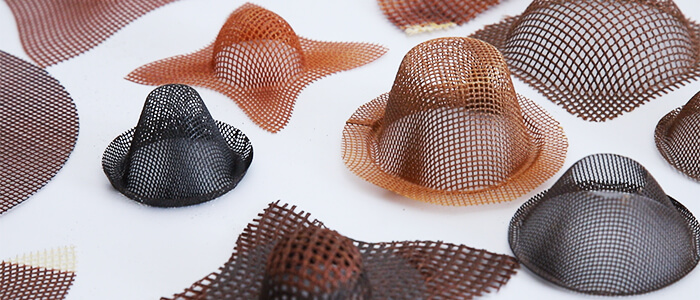

Materials and Structure of Cap-Shaped Fiberglass Mesh Filters for Casting

Material Composition

Fiberglass mesh caps are woven from alkali-free glass fiber yarns, and some high-end products are coated with refractory coatings to improve high temperature resistance and resistance to metal liquid scouring.

Temperature range: Due to different materials, the short-term tolerable temperature is also different. It is suitable for aluminum alloy, magnesium alloy, copper alloy, cast iron, cast steel, etc.

Structural design

The glass fiber mesh cap is usually conical or cylindrical, and can be directly put on the pouring cup, riser or installed on the automatic filtering equipment. Its structural features include:

- Mesh specifications: Common 1.0×1.0mm, 1.5×1.5mm, 2.0×2.0mm, 2.5×2.5mm, different filtration precisions can be selected according to the requirements of the casting.

- Size adaptation: It needs to match the pouring cup size of the pouring system, which can generally be customized.

Working principle of Cap-Shaped Fiberglass Mesh Filters

During the pouring process, when the molten metal flows through the mesh cap, its filtering mechanism mainly includes:

- Mechanical interception: The mesh can block larger particles of oxides, slag inclusions and other impurities.

- Adsorption: The surface of the glass fiber can adsorb tiny non-metallic inclusions.

- Flow stabilization: Make the metal liquid flow more smoothly and reduce secondary oxidation caused by turbulence.

Actual case:

After a certain aluminum alloy wheel hub foundry adopted glass fiber mesh cap, the slag inclusion defect rate of the casting was reduced by about 30%. At the same time, the porosity problem of the pouring system was also improved because the metal liquid flow was more stable.

Main application areas

Cap-Shaped Fiberglass Mesh Filters for Casting are widely used in the following casting scenarios:

Aluminum alloy casting

Automotive parts (engine cylinder block, wheel hub, gearbox housing, etc.)

Electronic equipment (radiator, housing, etc.)

Aerospace (some low-stress structural parts)

Magnesium alloy casting

3C products (laptop housing, mobile phone frame)

Lightweight components (car dashboard bracket, aviation seat components)

Copper alloy casting

Plumbing valve

Electrical connectors

Note: Due to the high pouring temperature of copper alloy (about 1000~1100°C), it is necessary to select a high-temperature resistant coating reinforced mesh cap and strictly control the pouring time to avoid premature failure of the filter.

Analysis of the Advantages and Disadvantages of Cap-Shaped Fiberglass Mesh Filters

Advantages

- Low cost: Compared with ceramic filters, the price is more competitive and suitable for mass production.

- Easy installation: directly put on the pouring cup, no complex fixing device is required.

- Improving casting quality: effectively reducing defects such as slag inclusions and pores, and improving the yield rate.

Limitations

Limited temperature resistance: it may soften under high temperature for a long time, and is not suitable for long-term high-melting-point metal pouring.

Low strength: it may be destroyed by molten metal during high-speed pouring, and the pouring system design needs to be optimized.

Common problems and solutions

Problem 1: Mesh cap cracked

Reason: pouring speed is too fast or temperature is too high.

Solution: optimize pouring process parameters and use mesh caps of other materials.

Problem 2: Poor filtering effect

Reason: mesh is too large or metal pretreatment is insufficient.

Solution: use finer mesh and strengthen melt purification (such as degassing and refining).

Conclusion

Cap-Shaped Fiberglass Mesh Filter is an economical and efficient filtering solution for casting of aluminum alloy, magnesium alloy, etc., which can significantly improve the quality of castings and reduce the scrap rate. However, its temperature resistance and strength are limited, and it needs to be reasonably selected according to the specific process.

Enterprises should choose the most suitable filtering technology based on their own production needs to achieve the best balance between casting quality and cost.

For further technical consultation, please contact SF-FOUNDRY for customized solutions.

- Email: info@sf-foundry.com

- WhatsApp: +8613785803358

SF-FOUNDRY, a professional casting filter material supplier