Introduction:

Photocatalysis is a promising technology that utilizes light energy to drive chemical reactions, offering numerous applications in environmental remediation, energy production, and materials synthesis. Ceramic foam filters, known for their high porosity and excellent thermal stability, have emerged as an effective medium for supporting photocatalysts. This essay explores the application of ceramic foam filters in photocatalysis, highlighting their unique properties, advantages, and contributions to enhancing the efficiency and effectiveness of photocatalytic processes.

Section 1: Ceramic Foam Filters in Photocatalysis

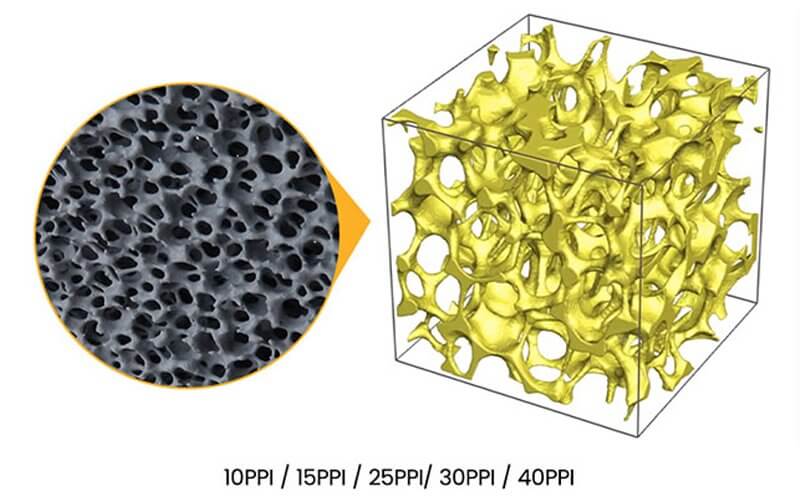

Ceramic foam filters, composed of a three-dimensional interconnected network of ceramic material, provide an ideal substrate for anchoring photocatalytic materials. The high porosity of ceramic foam filters allows for increased surface area, facilitating the deposition of photocatalysts and improving their exposure to incident light. This enhanced interaction between the catalyst and light leads to improved photocatalytic performance.

Section 2: Advantages of Ceramic Foam Filters in Photocatalysis

2.1. High Porosity and Surface Area: Ceramic foam filters offer a large surface area for the deposition of photocatalytic materials, maximizing the contact between the catalyst and the reactants. This increased surface area enhances the efficiency of photocatalytic reactions, allowing for higher conversion rates and improved performance.

2.2. Mechanical Stability and Durability: Ceramic foam filters provide excellent mechanical stability and durability, ensuring the integrity of the photocatalytic system during operation. They can withstand harsh reaction conditions, including high temperatures and corrosive environments, without undergoing significant degradation. This robustness ensures the longevity of the photocatalytic system, contributing to its long-term performance.

2.3. Heat and Mass Transfer: Ceramic foam filters facilitate efficient heat and mass transfer in photocatalytic systems. Their open-cell structure allows for easy transport of reactants and products, minimizing mass transfer limitations and promoting faster reaction rates. Additionally, ceramic foam filters possess good thermal conductivity, ensuring efficient heat dissipation during exothermic photocatalytic reactions.

2.4. Versatility in Catalyst Selection: Ceramic foam filters can accommodate various types of photocatalytic materials, such as titanium dioxide (TiO2), zinc oxide (ZnO), and other semiconductor-based catalysts. This versatility allows researchers and engineers to tailor the choice of photocatalyst based on the specific requirements of the target reaction.

Section 3: Applications of Ceramic Foam Filters in Photocatalysis

3.1. Water Treatment: Ceramic foam filters find application in photocatalytic water treatment processes, such as the degradation of organic pollutants and the disinfection of waterborne pathogens. By supporting photocatalysts on the filter’s surface, ceramic foam filters enhance the contact between the catalyst and water contaminants, leading to improved pollutant removal and water quality.

3.2. Air Purification: Ceramic foam filters are also utilized in photocatalytic air purification systems. These filters, coated with photocatalytic materials, can effectively degrade volatile organic compounds (VOCs), nitrogen oxides (NOx), and other air pollutants when exposed to light. Ceramic foam filters facilitate the adsorption of gaseous pollutants onto the catalyst surface, enhancing their photocatalytic degradation.

3.3. Energy Conversion: Ceramic foam filters play a role in photocatalytic energy conversion processes, such as water splitting for hydrogen production and solar fuel generation. By providing a suitable substrate for photocatalytic materials, ceramic foam filters contribute to efficient light absorption and electron-hole separation, leading to enhanced energy conversion efficiency.

3.4. Self-Cleaning Surfaces: Ceramic foam filters with photocatalytic coatings can be used to create self-cleaning surfaces. When exposed to light, the photocatalytic material on the filter surface can break down organic contaminants, such as dirt, grease, and pollutants, reducing the need for manual cleaning and maintenance.

3.5. Photocatalytic Materials Recovery: Ceramic foam filters can also facilitate the recovery and recycling of photocatalytic materials. By providing a porous medium, ceramic foam filters allow for the easy separation and collection of photocatalysts after the photocatalytic process. This feature contributes to resource conservation and cost-effectiveness in large-scale applications.

Section 4: Future Perspectives and Innovations

Ongoing research and development efforts focus on further enhancing the properties and performance of ceramic foam filters for photocatalysis. This includes the exploration of new ceramic materials, surface modifications, and the integration of advanced manufacturing techniques. Innovations aim to improve the photocatalytic activity, stability, and selectivity of ceramic foam filters, expanding their applications in environmental remediation, energy production, and other emerging areas.

Researchers are also investigating the combination of multiple photocatalytic materials or the incorporation of nanomaterials onto ceramic foam filters to enhance light absorption, charge separation, and catalytic activity. These advancements may lead to breakthroughs in photocatalytic efficiency and broaden the scope of photocatalysis applications.

Section 5: Environmental Benefits of Ceramic Foam Filters in Photocatalysis

The utilization of ceramic foam filters in photocatalysis brings about several environmental benefits. Firstly, photocatalysis offers a green and sustainable approach to addressing environmental pollution by promoting the degradation of organic contaminants and the removal of harmful substances from air and water sources. Ceramic foam filters enable the efficient implementation of photocatalysis, ensuring effective pollutant removal and reducing the impact of pollutants on ecosystems.

Moreover, the durability and longevity of ceramic foam filters contribute to their environmental sustainability. These filters can withstand harsh conditions and maintain their performance over extended periods, reducing the need for frequent replacements and minimizing waste generation. Additionally, the recovery and recycling of photocatalytic materials supported by ceramic foam filters promote resource conservation and reduce the environmental footprint associated with their production.

Section 6: Challenges and Considerations

While ceramic foam filters offer significant advantages in photocatalysis, several challenges and considerations must be addressed. Ensuring proper adhesion of photocatalytic materials to the filter surface, optimizing light absorption and distribution within the filter structure, and managing the potential loss of catalyst particles during operation are areas of ongoing research. Additionally, the scalability and cost-effectiveness of ceramic foam filters for large-scale applications remain important considerations in industrial implementation.

Conclusion:

Ceramic foam filters provide a versatile and effective medium for supporting photocatalytic materials, enhancing their performance and efficiency in various applications. With their high porosity, mechanical stability, and excellent heat and mass transfer properties, ceramic foam filters contribute to improved photocatalytic reactions in water treatment, air purification, and energy conversion. The ongoing research and development efforts in ceramic foam filters aim to further optimize their properties, expand their applications, and address the challenges associated with large-scale implementation. By harnessing the potential of ceramic foam filters in photocatalysis, researchers and industries can advance sustainable and environmentally friendly solutions for pollution control, resource utilization, and energy production.