In casting production, the purity of molten metal is directly related to the quality and performance of castings. Molten metal is easily mixed with oxides, slag or gas during the flow process. If these impurities are not effectively intercepted, the surface of the casting will be rough at best, and defects such as pores and cracks will be caused at worst. For this reason, filtration technology has become an indispensable part of modern casting technology. Ceramic filters and glass fiber filters are two mainstream casting filter materials. They have their own characteristics in practical applications and correspond to different production needs.

Ceramic filters: molten metal filtration for high-temperature precision casting

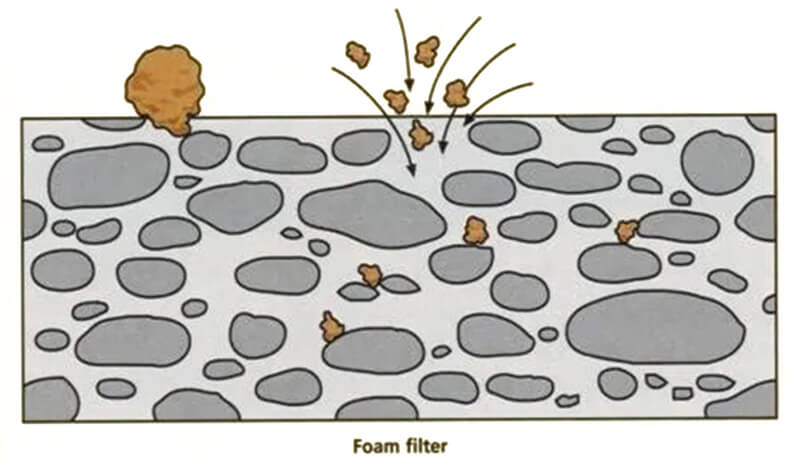

The core advantage of ceramic filters comes from their special material properties and structural design. It is usually made of a honeycomb or foam-like three-dimensional structure made of high-temperature ceramic materials such as silicon carbide and alumina. This porous ceramic structure can not only intercept large impurities in the molten metal, but also capture tiny particles through deep adsorption, thereby significantly improving the purity of the molten metal.

In high-temperature precision casting scenarios such as aluminum alloys and cast iron, the performance of ceramic filters is particularly outstanding. For example, in the production of aluminum alloy or cast iron parts, the temperature of the molten metal can reach above 700℃, and the high temperature stability of the ceramic material enables it to maintain structural integrity when in contact with the molten metal for a long time, avoiding secondary pollution caused by softening or disintegration. In addition, the three-dimensional pore structure of the ceramic filter optimizes the flow state of the molten metal. When the high-temperature molten metal flows through the filter, the originally turbulent flow will tend to be smooth, forming a laminar state. This feature effectively reduces the mixing of metal oxidation and bubbles, thereby improving the density and mechanical properties of the casting.

| Ceramic Foam Filter | Silicon Carbide Ceramic Foam Filter, Alumina Ceramic Foam Filter, Zirconia Ceramic Foam Filter |

| Pore Density (PPI) | 10–40 |

| Porosity (%) | 80-90 |

| Max Working Temperature (ºC) | 1000-1700 |

| Bending Strength(Mpa) | 0.8-1.0 |

| Compressive Strength (Mpa) | 1.0-1.2 |

| Thermal Shock Resistance (times/1100-0ºC) | 6 |

In the production of precision castings such as aircraft engine blades or automobile cylinders, the interception ability of ceramic filters for tiny inclusions can meet the almost demanding purity requirements. At the same time, with the popularization of automated production lines, the high dimensional accuracy and mechanical strength of ceramic filter sheets enable them to be adapted to the automatic placement of robotic arms, further improving production efficiency.

In actual production, the selection of filter materials often requires a balance between technical requirements and economic efficiency. For the production of large-scale and high-demand castings such as automotive parts and aerospace components, ceramic filters bring long-term benefits by reducing scrap rates and improving product consistency. The practice of a large automobile foundry shows that after the introduction of ceramic filters, the sand hole defect rate of engine cylinder castings has dropped by more than 40%, and the subsequent machining costs have also been reduced.

Glass fiber filter in casting

In contrast, the application logic of glass fiber filter is more focused on cost control and flexible adaptation. This mesh structure woven from glass fibers has unique value in casting or non-continuous production scenarios due to its light physical properties and a variety of selectable pore densities. For example, in small-batch casting or low-melting-point alloy processing, glass fiber mesh can not only meet basic filtering needs, but also significantly reduce material costs.

| Types | Working temperatures (ºC) | Melting point (ºC) | Sustaining working time (min.) | Tensile strength (kg/4ends) | gas evolution (cm3/g) |

| Steel liquid filtration | 1600-1620 | 1700 | 5 | 16 | 60 |

| Iron liquid filtration | 1400-1450 | 1700 | 10 | 8 | 60 |

| Copper liquid filtration | 1200 | 1700 | 10 | 6 | 60 |

| Aluminum liquid filtration | 700-800 | 900 | 10 | 6 | 30 |

| Cap-style filtration | – | – | – | – | – |

The core competitiveness of glass fiber lies in its chemical stability and plasticity. In the foundry workshop, workers can cut the filter mesh at will according to the size of the pouring system. This flexibility is particularly important for multi-variety, small-batch production models.

Selection of casting filters

In actual production, many foundries not only use ceramic filters or glass fiber filters, but also use them together to achieve a balance between performance and cost. For example, in the production of large iron castings, ceramic filters are used in the main runner to cope with the scouring of high-temperature molten metal, while glass fiber filters are used in branch gates or shrinkage systems to intercept minor impurities and reduce costs.

Another typical application is for multi-material composite castings. For example, when casting steel parts with embedded copper alloy structures, ceramic filters can be used in the area where high-temperature molten steel flows, while glass fiber meshes can be configured in the area where low-temperature copper is poured. This layered filtration strategy not only improves process adaptability, but also reduces the risk of defects caused by insufficient performance of a single filter material.

The combination of the two filter materials essentially reflects the casting process’s pursuit of “leanness” – it requires both the high-performance support of ceramic filters and the cost control through glass fiber meshes.

Conclusion

Ceramic filters and glass fiber filters are not simply substitutes, but complementary technical options in the casting process. Ceramic filters have become the core guarantee of high-end casting with their high-temperature stability and precision filtration capabilities; glass fiber meshes serve low- and medium-requirement scenarios with their economy and flexibility. The combination of the two not only reflects the foundry industry’s wisdom in balancing quality and cost, but also provides more possibilities for process innovation. In future development, this collaborative model may further promote the foundry technology towards efficiency, intelligence and sustainability.