Alumina ceramic foam filter is a key equipment used to purify molten metal, especially in the production process of aluminum and aluminum alloys. This filter effectively improves the quality of aluminum products with its unique structure and working principle, and plays an indispensable role in production.

Working Principle of Alumina Ceramic Foam Filter for Aluminium Filtration

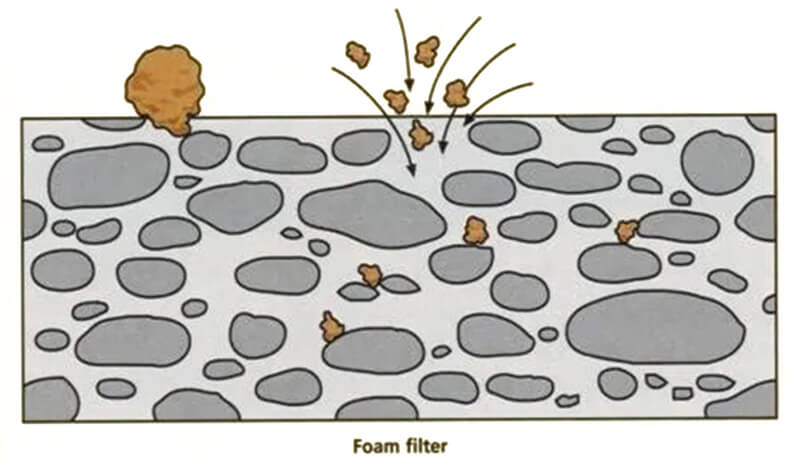

Alumina ceramic foam filter adopts the adsorption filtration principle. Its structure includes irregular multi-layer tortuous mesh, and the molten metal must pass through these tortuous channels to enter the cavity. In this process, large inclusions are captured on the surface of the filter to form a filter cake, while tiny inclusions are effectively adsorbed. In this way, the filter can efficiently remove impurities in the aluminum liquid and improve the purity of aluminum products.

Improve the Quality of Aluminum Products

The application of alumina ceramic foam filter significantly improves the quality of aluminum products:

- Remove inclusions: The alumina filter can effectively remove large and tiny inclusions in the aluminum liquid to ensure the purity of the aluminum product.

- Reduce pollution: Through the filtering effect, the filter reduces the degree of pollution to the aluminum liquid and improves the quality of the product.

- Improved microstructure: The ceramic filter helps improve the microstructure of aluminum products, improving the performance and surface quality.

Application Steps in Aluminum Production

In the aluminum production process, alumina ceramic foam filters are usually used in the following steps:

- Casting System: The ceramic foam filter can be placed in the pouring cup, the lower end of the guide system, etc., to purify the aluminum liquid.

- Aluminum Liquid Purification: Before the aluminum liquid flows to the cavity, the aluminum liquid is purified by the filter to remove inclusions.

- During the Casting Process: Ensure that the aluminum liquid is purified by the filter before entering the mold to improve product quality.

In summary, the alumina ceramic foam filter plays a vital role in aluminum production through its unique working principle and structural design, improves the quality and production efficiency of aluminum products, and ensures the smooth progress of the production process.