Introduction

In the foundry industry, the quality of hot metal directly determines the performance and yield of castings. Non-metallic inclusions in hot metal (such as oxides, slag inclusions, etc.) are one of the main causes of casting defects. In order to effectively remove these impurities, silicon carbide foam ceramic filters came into being and gradually became the mainstream choice for hot metal filtration. This article will deeply explore the working principle, technical advantages and application value of silicon carbide foam ceramic filters in hot metal filtration.

Working Principle of Silicon Carbide Foam Ceramic Filter

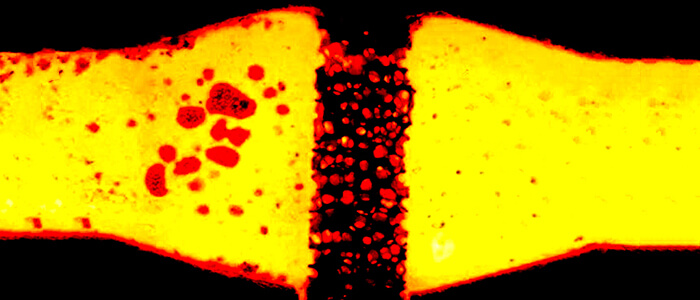

Silicon carbide foam ceramic filter is a porous filter material. Its core working principle is to remove impurities in hot metal through physical interception and adsorption. The specific process is as follows:

- Physical interception: The three-dimensional mesh structure of the filter can effectively capture large particle inclusions in hot metal.

- Adsorption: The chemical properties of the filter surface can adsorb tiny particles, further improving the filtration accuracy.

- Turbulence control: The porous structure of the filter can adjust the flow rate of hot metal, reduce turbulence, and make impurities easier to capture.

Technical advantages of silicon carbide foam ceramic filters

Compared with traditional filter materials, silicon carbide foam ceramic filters have the following significant advantages:

- Excellent high temperature resistance: Silicon carbide materials can work stably in high temperature environments above 1600℃, and are suitable for filtering high temperature melts such as molten iron and molten steel.

- Strong chemical stability: Silicon carbide has extremely high corrosion resistance to acids, alkalis and molten metals, ensuring long-term use of the filter under harsh working conditions.

- High porosity and uniform pore size: The porosity of the filter is as high as 80%-90%, and the pore size distribution is uniform, which can effectively remove impurities of different sizes.

- High strength and thermal shock resistance: Silicon carbide materials have high mechanical strength, can withstand rapid temperature changes, and reduce the risk of cracking.

- Environmental protection and economy: Through efficient filtration, casting defects are reduced, scrap rates are reduced, thereby saving costs and reducing resource waste.

Application of silicon carbide foam ceramic filters in molten iron filtration

In the casting process, molten iron filtration is a crucial link. Silicon carbide foam ceramic filters are widely used in the following scenarios:

- Remove inclusions: effectively filter non-metallic impurities such as oxides and slag inclusions in molten iron to improve the purity of castings.

- Improve casting performance: significantly improve the mechanical properties (such as tensile strength, toughness) and surface quality of castings by reducing the impurity content.

- Improve yield rate: reduce casting defects (such as pores and cracks) caused by impurities, thereby improving production efficiency and yield rate.

- Adapt to a variety of casting processes: suitable for sand casting, lost foam casting, centrifugal casting and other casting processes to meet the needs of different customers.

Practical application cases

Take a foundry as an example. The plant used SF-FOUNDRY’s silicon carbide foam ceramic filter in the molten iron filtration link and achieved remarkable results:

- Reduced casting defect rate: through filtration, the pore and slag inclusion defect rate of castings was reduced from the original 5% to less than 1%.

- Improved production efficiency: the fluidity of filtered molten iron is enhanced, the pouring time is shortened, and the production efficiency is increased by 15%.

- Cost saving: The scrap rate is reduced, saving about 500,000 yuan per year.

Future development trend

With the continuous improvement of casting quality requirements in the foundry industry, the application prospects of silicon carbide foam ceramic filters are very broad. Future development directions include:

- Higher precision filtration: Develop filters with smaller pore sizes to meet the needs of high-purity metals in the high-end manufacturing field.

- Intelligent filtration system: Combine sensors and Internet of Things technology to achieve real-time monitoring and optimization of the filtration process.

- Environmental protection and sustainable development: Develop recyclable or degradable filter materials to further reduce the impact on the environment.

Conclusion

Silicon carbide foam ceramic filters have become an indispensable key material in the field of molten iron filtration due to their excellent high temperature resistance, chemical stability and high-efficiency filtration performance. As an industry-leading manufacturer of silicon carbide foam ceramic filters, SF-FOUNDRY will continue to be committed to technological innovation, provide customers with better products and services, and help the foundry industry achieve high-quality and sustainable development.

About SF-FOUNDRY

SF-FOUNDRY is a high-tech enterprise focusing on the research, development, production and sales of silicon carbide foam ceramic filters. With years of technical accumulation and industry experience, SF-FOUNDRY has become a leading brand in the global industrial filtration field. Its products are sold at home and abroad and are deeply trusted by customers.

Contact Us

For more information about silicon carbide foam ceramic filters, please visit our official website or contact our sales team.

Email: info@sf-foundry.com

WhatsApp: +8613785803358