Aluminum is one of the most widely used metals in the world for its versatility, lightweight, and durability. In Turkey, the manufacturing industry is one of the fastest growing sectors and it heavily relies on aluminum foundries for various applications. Aluminum foundries in Turkey have been serving various industries such as automotive, construction, aerospace, and defense. This article aims to provide a comprehensive analysis of the distribution and data of aluminum foundries in Turkey, as well as the application and market of Aluminum Ceramic Foam filters in foundries.

Distribution and Data of Aluminum Foundries in Turkey

Turkey has a rich history in metal casting and is one of the leading countries in the world in terms of manufacturing aluminum products. According to the Turkish Foundrymen’s Association, there are approximately 1300 foundries in Turkey with a total production capacity of 3.5 million tons per year. Out of these foundries, around 200 are aluminum foundries which produce approximately 300,000 tons of aluminum products per year.

The distribution of aluminum foundries in Turkey is uneven, with the majority concentrated in the Marmara region, which includes Istanbul, Kocaeli, and Bursa. These regions have a highly developed infrastructure, skilled workforce, and a well-established supply chain network for raw materials. In addition to this, the regions have a favorable location for exports, which makes them a hub for the aluminum industry in Turkey.

The remaining aluminum foundries are located in the Aegean, Mediterranean, and Central Anatolian regions. The Aegean region has a significant number of aluminum foundries due to the presence of a thriving shipbuilding industry in the region. The Mediterranean region, on the other hand, has a large number of foundries that produce aluminum products for the construction industry. The Central Anatolian region has a relatively low number of aluminum foundries with most of them producing specialty products such as aluminum jewelry and home decor.

Application of Aluminum Ceramic Foam Filter in Foundries

Aluminum foundries are faced with various challenges in producing high-quality aluminum products. One of the major challenges is the presence of impurities in the molten aluminum, which affects the quality of the final product. To overcome this challenge, foundries use ceramic foam filters to remove impurities from molten aluminum.

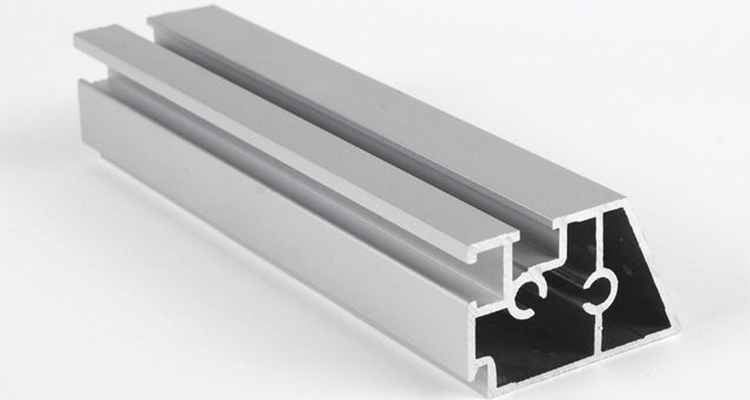

Ceramic foam filters consist of a porous ceramic structure with a high specific surface area. The filter’s porous structure traps impurities such as oxides, slag, and inclusions, which are then removed from the molten aluminum. The filters help in improving the quality of the final product by reducing porosity, increasing mechanical strength, and improving the surface finish.

The use of ceramic foam filters in aluminum foundries has become increasingly popular due to its ability to reduce production costs by increasing the yield and reducing the amount of scrap produced. Ceramic foam filters can be used in various applications such as sand casting, investment casting, continuous casting, and die casting.

Market of Aluminum Ceramic Foam Filter in Foundries

The use of aluminum ceramic foam filters in foundries has been growing rapidly over the past few years due to their advantages over traditional filtration methods. According to a report by QY Research, the global market for ceramic foam filters was valued at USD 112.0 million in 2020 and is expected to reach USD 140.5 million by 2027, with a CAGR of 3.1% during the forecast period.

The growth of the market for ceramic foam filters can be attributed to the increasing demand for high-quality aluminum products and the increasing awareness about the benefits of using ceramic foam filters. The growing need for lightweight products in industries such as automotive and aerospace is expected to further drive the demand for aluminum products and, in turn, the market for ceramic foam filters.

In Turkey, the market for ceramic foam filters is still in the nascent stage, with most of the foundries still using traditional filtration methods. However, the demand for high-quality aluminum products is increasing, and foundries are looking for ways to improve their production processes. The use of ceramic foam filters in foundries is expected to grow in the coming years. However, the high cost of ceramic foam filters remains a major challenge for many foundries in Turkey.

Conclusion

Aluminum foundries in Turkey play a crucial role in supplying aluminum products to various industries such as automotive, construction, aerospace, and defense. The distribution of aluminum foundries in Turkey is uneven, with the majority concentrated in the Marmara region. The use of ceramic foam filters in foundries has become increasingly popular due to its ability to improve the quality of the final product and reduce production costs. The market for ceramic foam filters in Turkey is still in the nascent stage, but with the increasing demand for high-quality aluminum products, the use of ceramic foam filters in foundries is expected to grow in the coming years.