Aluminum filtration is an indispensable and key step in the casting process of aluminum and aluminum alloys. Its main purpose is to remove non-metallic inclusions, oxides and other impurities in aluminum water through efficient filtration, thereby improving the purity and quality of castings and optimizing the mechanical properties and surface finish of aluminum alloys. With the growing demand for high-performance aluminum alloy products in the casting industry, the importance of aluminum water filtration technology has become increasingly prominent.

Common sources of impurities in aluminum water

During the smelting and pouring of aluminum water, the generation of impurities is inevitable, mainly including the following:

Non-metallic inclusions

- Mainly derived from the contamination of the melt by aluminum ingots, flux and tools.

- Common non-metallic inclusions include alumina (Al₂O₃), carbide and silicide particles.

Secondary oxide inclusions

When aluminum water is exposed to air, it is easy to form oxide films, which may be broken into inclusions during the stirring or pouring of the melt.

Gaseous impurities

Hydrogen dissolved in the melt may precipitate when cooling, resulting in porosity defects in castings.

Necessity of aluminum water filtration

Direct pouring of unfiltered aluminum water may cause the following problems:

- Internal defects in castings: Inclusions or pores may form defects in castings, reducing the mechanical properties of the material.

- Degradation of surface quality: Impurities may affect the finish of the casting surface, requiring additional machining processes.

- Uneven casting performance: Uneven distribution of impurities may cause local performance degradation of castings, affecting overall reliability.

By filtering aluminum water, impurities in the melt can be effectively removed, significantly improving the quality and performance of castings.

Core technology of aluminum water filtration: ceramic foam filter

Ceramic foam filter is one of the most commonly used equipment for aluminum water filtration, among which alumina ceramic foam filter is widely used for its efficient filtration performance. Its structural characteristics and performance are as follows:

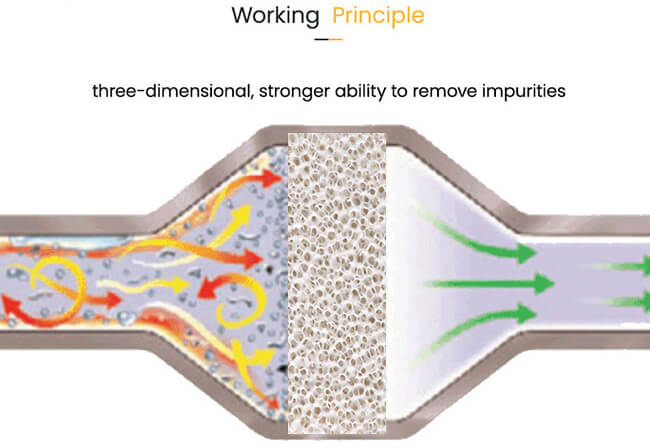

Three-dimensional porous structure

The unique mesh pore design gives the filter a large specific surface area and high permeability, which can effectively capture non-metallic inclusions in aluminum water.

High temperature tolerance

The operating temperature of alumina ceramic foam filter can reach above 1000℃, which fully meets the high temperature conditions of aluminum water filtration.

High chemical stability

It has excellent corrosion resistance to the components in molten aluminum and will not contaminate the melt.

High filtration efficiency

The pore size range (10-60 PPI) can be selected according to needs, which can not only efficiently remove impurities but also maintain the fluidity of molten aluminum.

Flow of molten aluminum filtration

Filter preheating

Before filtration, the ceramic filter needs to be preheated (usually between 300℃-600℃) to avoid thermal shock damage caused by excessive temperature difference when molten aluminum contacts the filter.

Molten aluminum casting

The molten aluminum is filtered through the filter, which can capture non-metallic inclusions and oxides while allowing pure aluminum to pass through.

Regularly replace the filter

After long-term use, the pores of the filter may be filled with impurities, affecting the filtration efficiency and need to be replaced in time.

Advantages of aluminum filtration

Through efficient filtration, aluminum filtration technology can bring the following benefits to foundries:

Improve the quality of castings

After removing impurities, the mechanical properties, surface finish and internal density of the castings are significantly improved, meeting the quality requirements of high-end aluminum products.

Reduce production costs

Reduce the defective rate and rework rate of castings, optimize the production process, and reduce the overall manufacturing cost.

Improve casting efficiency

The filtered aluminum water has better fluidity, which helps to improve the pouring efficiency and shorten the production cycle.

SEFU Foam Ceramic Filter: Ideal for Aluminum Water Filtration

As a professional foam ceramic filter manufacturer, SEFU provides high-quality alumina foam ceramic filters, which are specially designed for aluminum and aluminum alloy melt filtration. Our products have the following characteristics:

- High-efficiency filtration: significantly reduce inclusions and improve the purity of aluminum water.

- Customized service: a variety of specifications are available to meet the different process requirements of customers.

- Strong durability: stable high temperature performance and long service life.

Whether in the automotive, aerospace, or industrial manufacturing fields, SEFU foam ceramic filters can provide reliable support for aluminum casting production.

Contact Us

If you need to know more about aluminum water filtration or foam ceramic filter products, please feel free to contact us:

Official website: www.sf-foundry.com

Tel: +8613785803358

Email: info@sf-foundry.com

SEFU looks forward to working with you to jointly promote the high-quality development of the foundry industry!