I. Introduction

A. Background

In industrial processes such as metal casting and foundry operations, the removal of impurities from molten metals is crucial to ensure the production of high-quality and defect-free products. Traditional filtration methods have limitations in terms of efficiency and consistency. Alumina ceramic foam filter has emerged as a reliable solution to overcome these challenges.

B. Purpose of the Essay

This essay aims to provide a comprehensive overview of alumina ceramic foam filters, their filtration mechanisms, advantages, applications, performance factors, selection guidelines, and a comparison with alternative filtration methods. Furthermore, it will discuss case studies, challenges, future trends, and developments in the field.

II. Alumina Ceramic Foam Filter: Overview

A. Definition and Composition

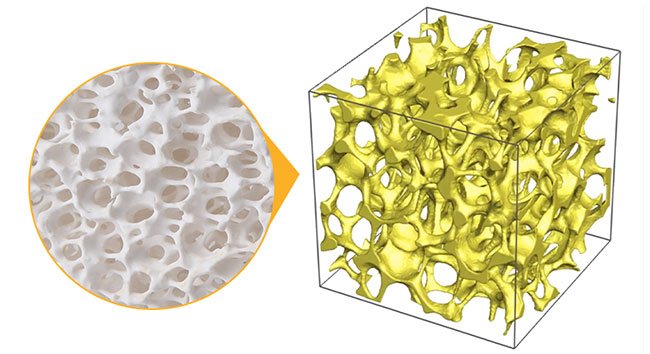

Alumina ceramic foam filters are three-dimensional, open-cell structures composed of high-purity alumina ceramics. They are designed to remove impurities, gases, and inclusions from molten metals during casting and foundry processes.

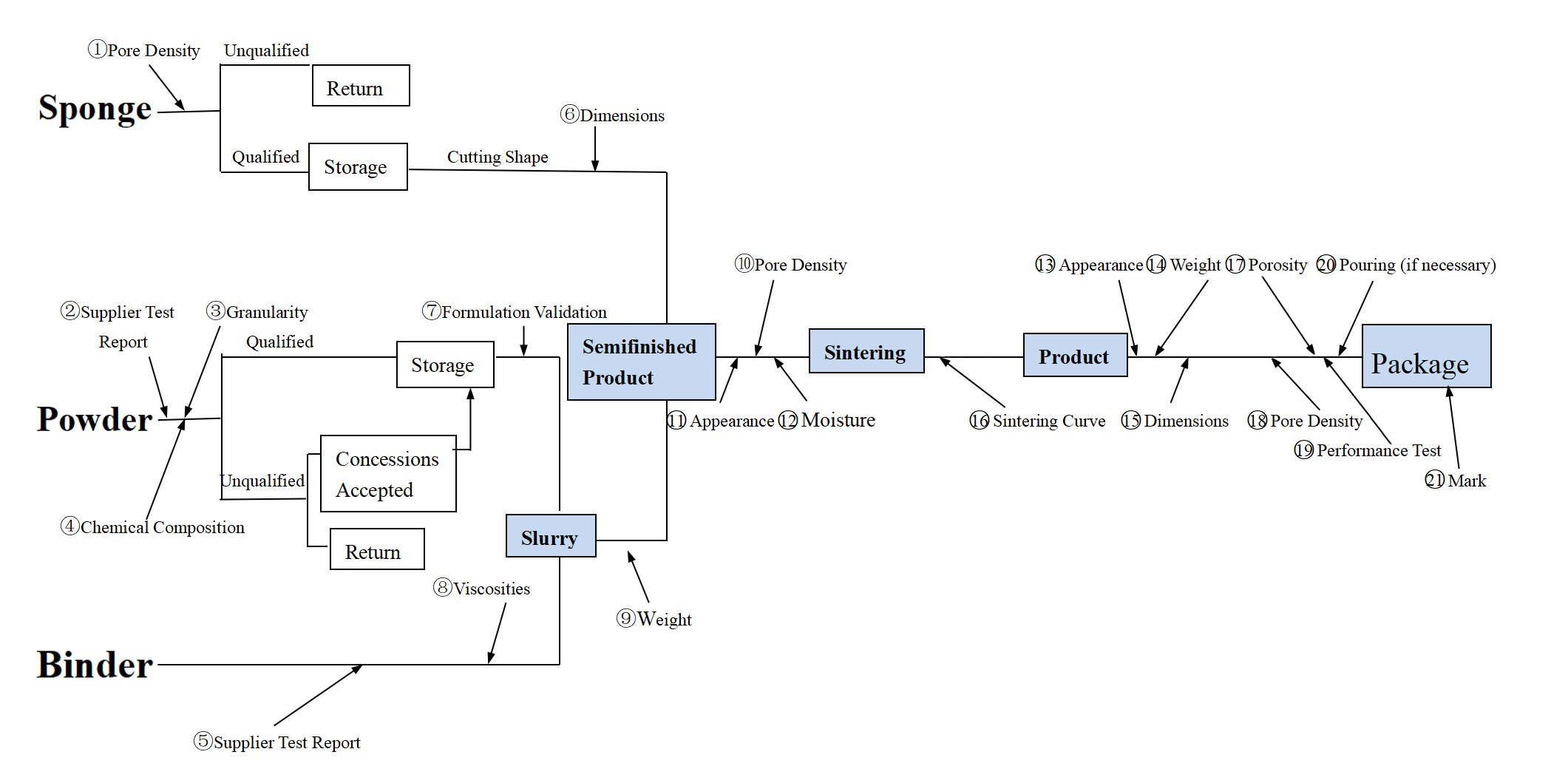

B. Manufacturing Process

The production of alumina ceramic foam filters involves several steps, including raw material preparation, foam formation, drying, and firing. The resulting filters possess a uniform and interconnected porosity, enabling effective filtration.

C. Structure and Properties

Alumina ceramic foam filters exhibit a reticulated structure with evenly distributed pores. The filters offer high-temperature resistance, excellent thermal shock resistance, and good mechanical strength. Their properties can be tailored by adjusting the pore size and distribution.

III. Filtration Mechanism

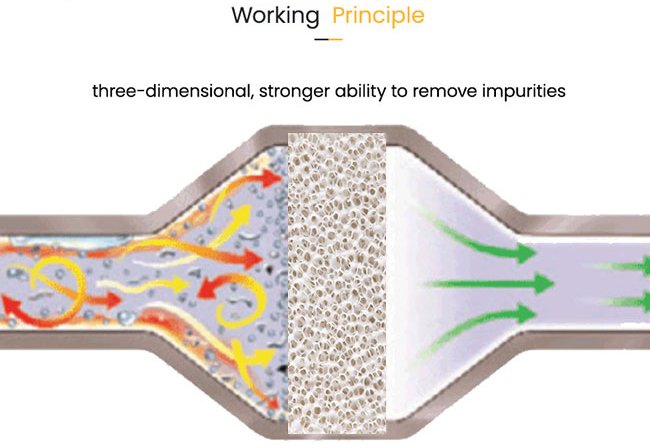

A. Understanding Filtration

Filtration involves the removal of unwanted particles or impurities from a fluid or molten metal. Various mechanisms such as inertial impaction, interception, and diffusion contribute to the filtration process.

B. Role of Alumina Ceramic Foam Filters

Alumina ceramic foam filters act as a physical barrier, trapping impurities and allowing the clean metal to pass through. The unique structure of the filters facilitates the efficient capture of particles based on size, density, and shape.

IV. Applications of Alumina Ceramic Foam Filters

A. Foundry Industry

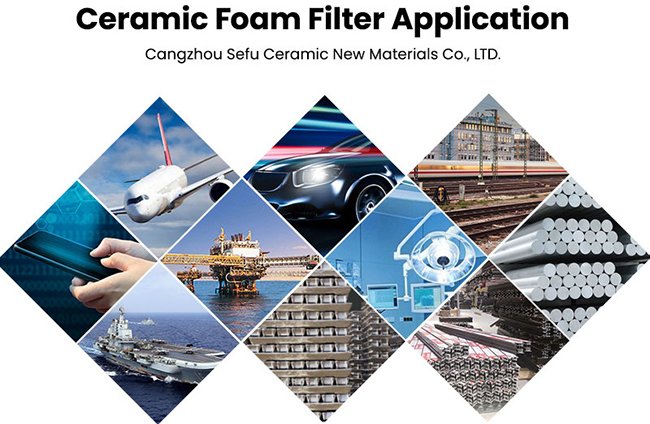

Alumina ceramic foam filters find extensive use in the foundry industry, where they are employed for gating systems, mold filling, and casting of various metals and alloys.

B. Metal Casting Processes

The filters are widely utilized in metal casting processes such as investment casting, sand casting, permanent mold casting, and die casting, ensuring the production of high-quality castings.

C. Molten Metal Filtration

Alumina ceramic foam filters are also employed for molten metal filtration in industries like automotive, aerospace, and steel production, where the removal of impurities is critical.

V. Advantages and Benefits

A. Enhanced Filtration Efficiency

Alumina ceramic foam filters offer superior filtration efficiency compared to traditional filters, resulting in cleaner metal with reduced inclusions, defects, and gas porosity.

B. Improved Metal Quality

By removing impurities and oxides, alumina ceramic foam filters contribute to the production of high-quality metals with improved mechanical properties and surface finish.

C. Extended Service Life

The filters’ excellent thermal shock resistance and mechanical strength ensure longer service life, reducing downtime and replacement costs.

VI. Performance Factors

A. Pore Size and Distribution

The choice of appropriate pore size and distribution plays a crucial role in achieving the desired filtration efficiency and metal quality.

B. Filtration Capacity

The filtration capacity of alumina ceramic foam filters is influenced by factors such as filter thickness, porosity, and molten metal flow rate.

C. Pressure Drop

Pressure drop across the filter is a critical performance factor, affecting the overall efficiency and productivity of the casting process.

VII. Selection and Usage Guidelines

A. Filter Size and Shape

Choosing the correct filter size and shape based on the casting process requirements is essential to ensure optimal filtration performance.

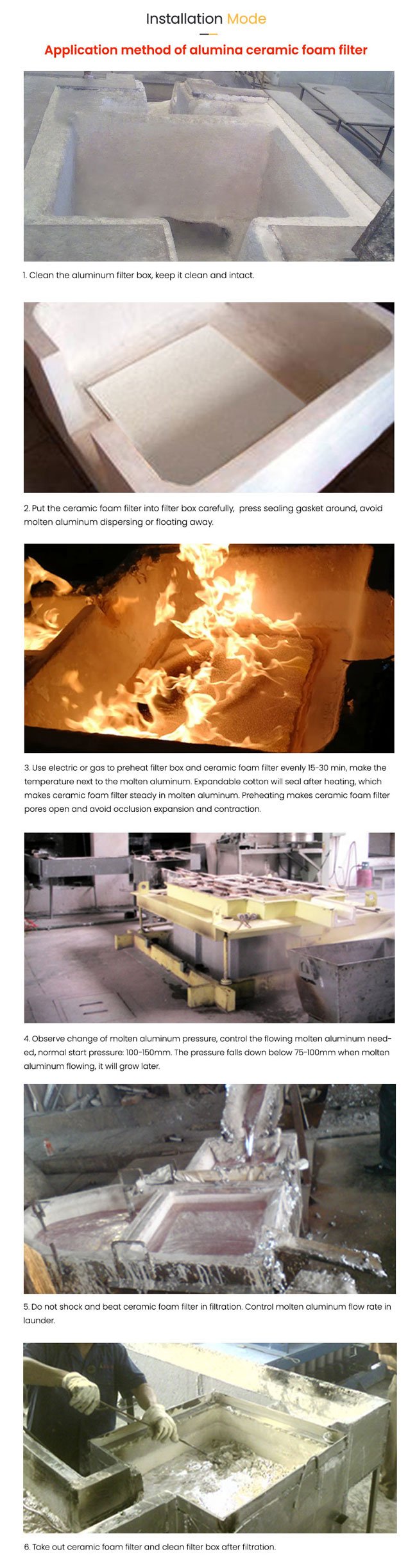

B. Proper Installation Techniques

The proper installation of alumina ceramic foam filters, including preheating, positioning, and securing, is crucial for achieving consistent and reliable filtration results.

C. Maintenance and Cleaning

Regular maintenance, cleaning, and replacement of filters are necessary to prevent clogging and ensure continuous filtration performance.

VIII. Comparison with Other Filtration Methods

A. Sand Filters

Compared to sand filters, alumina ceramic foam filters offer superior filtration efficiency, reduced metal loss, and improved dimensional accuracy.

B. Fiber Filters

Alumina ceramic foam filters outperform fiber filters in terms of mechanical strength, thermal shock resistance, and filtration capacity.

IX. Case Studies and Industrial Success Stories

A. Automotive Industry

Several automotive manufacturers have successfully implemented alumina ceramic foam filters to enhance casting quality and reduce defects in engine components.

B. Aerospace Industry

Alumina ceramic foam filters have gained significant traction in the aerospace industry, ensuring the production of high-performance, lightweight alloys used in aircraft components.

C. Steel Production

In the steel industry, alumina ceramic foam filters have enabled the removal of impurities and inclusions, resulting in improved steel quality and enhanced mechanical properties.

X. Challenges and Limitations

A. High Initial Cost

The initial cost of alumina ceramic foam filters is relatively higher than traditional filters, which may pose a barrier to their adoption in certain applications.

B. Clogging and Breakage

In some cases, the filters may experience clogging due to excessive impurities or breakage due to mishandling, leading to decreased filtration efficiency.

C. Specific Applications Limitations

Alumina ceramic foam filters have limitations in specific applications that involve highly corrosive or reactive molten metals, requiring alternative filtration methods.

XI. Future Trends and Developments

A. Innovations in Filter Design

Ongoing research aims to improve the filter design by optimizing pore structure, enhancing mechanical strength, and incorporating advanced coatings for specific applications.

B. Advanced Manufacturing Techniques

Emerging manufacturing techniques, such as additive manufacturing, hold the potential to enhance the production efficiency and customization of alumina ceramic foam filters.

XII. Summary

Alumina ceramic foam filters offer a reliable and efficient solution for the removal of impurities from molten metals in various industrial processes. Their unique structure, coupled with excellent properties, ensures enhanced filtration efficiency, improved metal quality, and extended service life. Proper selection, installation, and maintenance guidelines are crucial for achieving optimal performance. While challenges and limitations exist, ongoing research and advancements in filter design and manufacturing techniques promise a bright future for alumina ceramic foam filters in the industrial sector.

XIII. Conclusion

Alumina ceramic foam filters have revolutionized the field of molten metal filtration by offering enhanced efficiency and improved metal quality. Their versatile applications, coupled with the benefits they provide, make them indispensable tools in industries such as foundry, metal casting, and molten metal filtration. With further advancements and ongoing research, alumina ceramic foam filters are poised to play a vital role in ensuring high-quality metal production and contributing to the advancement of various industrial processes.