Air filtration technology has become an essential part of modern industrial processes. With increasing air pollution and health concerns, manufacturers are mandated to ensure that clean air is exhausted into the environment. Various methods exist for air filtration, which include dry scrubbers, wet scrubbers, and electrostatic precipitators. However, the use of ceramic foam filters coated with titanium dioxide (TiO2) has provided an effective and sustainable solution to air filtration.

Germany has been at the forefront of air filtration technology development, with several companies innovating and manufacturing ceramic foam filters coated with TiO2. This article highlights the advantages of ceramic foam filters coated with TiO2 and how German companies have emerged as leaders in this technology. The article also discusses the growing market for ceramic foam filters coated with TiO2 and the future prospects for this technology.

Advantages of Ceramic Foam Filters Coated with TiO2 Technology

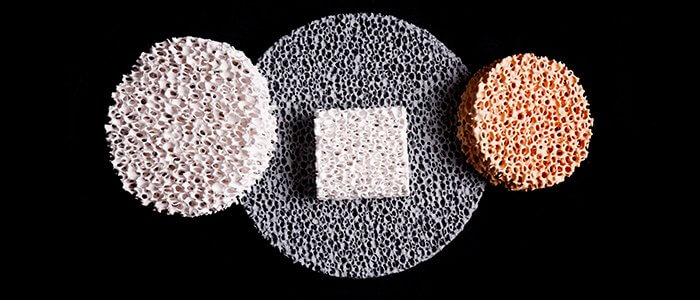

Ceramic foam filters are widely used in several industrial processes, including foundries, petrochemicals, and power generation. These filters are made from silicon carbide, aluminum oxide, or zirconia oxide foam that is coated with other materials to provide selective filtration of specific pollutants.

Ceramic foam filters coated with TiO2 have several advantages over other filtration systems, which include:

1. High Filtration Efficiency

Ceramic foam filters coated with TiO2 have high filtration efficiency, with the capacity to remove up to 99% of particulate matter and volatile organic compounds (VOCs). The filters trap pollutants through a photocatalysis process, where TiO2 particles in the filter surface react with UV light to produce reactive oxygen species that destroy pollutants.

2. Long Service Life

Ceramic foam filters coated with TiO2 have a long service life, making them cost-efficient in industrial processes. The filters are resistant to high temperatures, chemical corrosion, and mechanical wear and tear. This allows the filter to be reused for several cycles before replacing or cleaning, reducing the production cost of filtration systems.

3. Eco-Friendly

The use of ceramic foam filters coated with TiO2 is an eco-friendly solution to air pollution. The filters produce no secondary pollutants, are recyclable, and have fewer carbon emissions compared to other filtration systems. This technology aligns with the sustainability goals of manufacturers and regulatory agencies, reducing the environmental impact of industrial processes.

German Air Filtration Technology: Ceramic Foam Filters Coated with TiO2 Market Leaders

Germany has several companies manufacturing and supplying ceramic foam filters coated with TiO2. These companies have invested in research and development of the technology, resulting in high-quality products and customer-focused innovations. The market leaders in Germany’s ceramic foam filters coated with TiO2 technology include:

1. Mullitec Industries GmbH

Mullitec Industries GmbH is a German company with extensive experience in ceramic foam filter manufacturing. The company specializes in manufacturing high-quality ceramic foam filters coated with TiO2 for foundries, ceramics, and petrochemical industries. Mullitec Industries GmbH produces filters with excellent mechanical strength, high filtration efficiency, and durability. The company also provides customer-specific filters configured to meet the specific air filtration needs of various industries.

2. Wazau GmbH

Wazau GmbH has been in the air filtration industry for over 20 years, providing customers with sustainable air filtration solutions through ceramic foam filters coated with TiO2 technology. The company produces filters with high filtration efficiency, durability, and long service life. The filters are used in several industrial processes, including automotive, food, and chemical industries. Wazau GmbH also offers custom filter designs to meet the unique air filtration needs of different industries.

3. Rauschert GmbH

Rauschert GmbH is a German company that has been in the ceramic foam filter manufacturing industry for over a century. The company specializes in producing ceramic foam filters coated with TiO2 for molten metal filtration, emission reduction, and exhaust gas treatment. Rauschert GmbH has a range of filters that provide high filtration efficiency, durability, and maintenance convenience. The company’s filters are also recyclable and environment-friendly.

Growing Air Filtration Market for Ceramic Foam Filters Coated with TiO2

The air filtration industry is experiencing rapid growth globally, driven by regulatory policies, health concerns, and the adoption of sustainable manufacturing processes. The market for ceramic foam filters coated with TiO2 is also growing, with manufacturers investing heavily in research and development of the technology. The market growth is attributed to several factors, which include:

1. Increased Demand for Sustainable Air Filtration Solutions

The current trend in the manufacturing industry is the adoption of sustainable practices, which include reducing carbon emissions and minimizing environmental impact. The use of ceramic foam filters coated with TiO2 aligns with this trend, as it provides a sustainable air filtration solution that reduces secondary pollutants, has high energy efficiency, and has a long service life.

2. Stringent Government Regulations

Governments globally have enacted stringent air quality regulations that industries must comply with. The use of ceramic foam filters coated with TiO2 provides an effective solution to meet these regulations and maintain clean air quality standards.

3. Health Concerns

The increasing awareness of the health effects of air pollution has led to heightened demand for air filtration solutions. Ceramic foam filters coated with TiO2 offer an effective solution to removing pollutants, thus reducing the health risks associated with polluted air.

Conclusion

Ceramic foam filters coated with TiO2 technology are a sustainable air filtration solution that offers high filtration efficiency, durability, and environmental friendliness. The German air filtration industry has emerged as a leader in this technology, with several companies investing in research and development of high-quality filters. The growing market for ceramic foam filters coated with TiO2 is attributed to increased demand for sustainable air filtration solutions, health concerns, and stringent government regulations. The technology presents a bright future for the air filtration industry, with the potential to revolutionize the way industries approach air filtration.