Turkey has been a hub for manufacturing and production for thousands of years. The country’s strategic location between the East and the West has made it an attractive place for trade and commerce. In recent years, Turkey’s emphasis on developing its manufacturing sector has led to the growth of its foundries, which are poised to become a major contributor to the country’s economy. Foundries in Turkey have been quick to adopt innovative technologies, such as silicon carbide ceramic foam filters and ceramic gating, in order to improve their processes and increase their efficiency.

Foundries in Turkey have traditionally operated using the sand casting method. This involves creating a mold made of sand that is then filled with molten metal to create the desired product. However, this method is not without its challenges. Sand casting can lead to defects in the castings, such as porosity and inclusions, which can weaken the structural integrity of the final product. In addition, sand casting can result in a large amount of waste material, which can be expensive to dispose of.

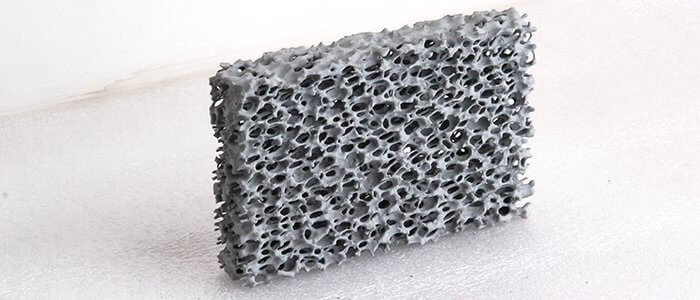

Silicon Carbide Ceramic Foam Filters

To overcome these challenges, foundries in Turkey have turned to silicon carbide ceramic foam filters. These filters are used to remove impurities from the liquid metal, such as dirt, sand, and oxides, before it is poured into the mold. The filter is made up of a porous ceramic material, which traps the impurities and allows the clean metal to pass through. The use of silicon carbide ceramic foam filters has led to a significant reduction in casting defects, resulting in higher-quality castings. In addition, the use of these filters has reduced the amount of waste material produced, as the impurities are trapped in the filter and can be disposed of easily.

Ceramic Gating

Ceramic gating is another technology that has been adopted by foundries in Turkey. This method involves the use of ceramic tubes and blocks to control the flow of the molten metal into the mold. The ceramic gating system is designed to minimize turbulence in the liquid metal, which can lead to defects in the casting. By controlling the flow of the molten metal, ceramic gating can also help to reduce the amount of waste material produced.

Application Cases

There are many examples of the successful use of silicon carbide ceramic foam filters and ceramic gating in foundries in Turkey.

One such example is the casting of pump parts for the oil and gas industry. Foundries in Turkey that produce pump parts have been able to improve the quality of their castings by using silicon carbide ceramic foam filters. The use of these filters has resulted in a significant reduction in porosity and inclusions, leading to stronger and more durable pump parts.

Another example is the casting of automotive engine components. Foundries in Turkey that produce engine components have been able to improve their processes and increase their efficiency by using ceramic gating. The use of ceramic gating has allowed for better control over the flow of the molten metal, resulting in a reduction in waste material and an increase in the quality of the castings.

Other Advanced Technologies

In addition to the use of silicon carbide ceramic foam filters and ceramic gating, foundries in Turkey are also investing in other advanced technologies, such as 3D printing and automation. These technologies are helping to further improve the efficiency and quality of the casting process.

Conclusion

In conclusion, foundries in Turkey have made significant advancements in their processes and technologies in recent years. The adoption of silicon carbide ceramic foam filters and ceramic gating has led to higher-quality castings and reduced waste material. Foundries in Turkey are poised to become major players in the global manufacturing industry, and their innovative spirit and commitment to quality will continue to drive their growth and success.