In the world of foundry technology, optimizing the casting process is crucial to improving efficiency, reducing waste, and ensuring high-quality results. One innovative solution that has gained traction in recent years is the use of paper casting runners. These paper-based components are revolutionizing the way gating systems are designed and function in certain casting applications. In this comprehensive guide, we will explore the applications, benefits, and design principles of paper casting runners, focusing primarily on their use in iron casting processes like lost foam casting and traditional sand casting.

What are Paper Casting Runners?

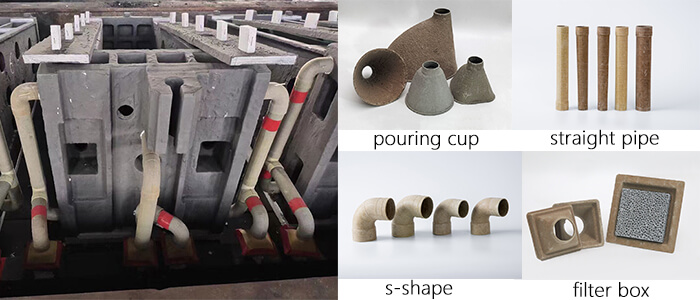

A paper casting runner is a component of a gating system made from specialized paper materials. These runners are used to channel molten metal into the mold cavity during the casting process. Unlike traditional metal runners, which are typically made from cast iron, steel, or other metals, paper casting runners are lightweight, cost-effective, and environmentally friendly. They are designed to provide a controlled flow of molten metal, reducing waste and improving the efficiency of the casting process.

How Paper Casting Runners Work

In a traditional foundry, the gating system—comprising the sprue, runners, and risers—plays a critical role in directing the flow of molten metal into the mold. Paper casting runners function similarly to metal runners, but with significant advantages in terms of material properties. These runners are typically created by molding paper fibers into specific shapes, ensuring strength and heat resistance while maintaining a lighter and more cost-effective solution.

Paper casting runners are often used in foundries where sustainability is a priority, and where cost savings are a key consideration. They can be integrated seamlessly into both lost foam casting and traditional sand casting processes, provided that the metal used is compatible (such as iron or steel).

Applications of Paper Casting Runners

Paper casting runners are primarily used in the following types of casting:

Lost Foam Casting (EPC – Expendable Pattern Casting)

Lost foam casting, a process where the pattern is made of foam and then vaporized during metal pouring, is particularly well-suited for paper casting runners. Since the foam pattern evaporates, the paper runner, which is designed to dissipate heat quickly, complements the rapid cooling process and allows for a precise, consistent metal flow.

Traditional Sand Casting

In sand casting, the paper casting runner system serves as an alternative to metal runners, providing a lightweight, adaptable system that improves metal flow into the mold. It is especially useful in large, complex molds where traditional metal runners might be more cumbersome or expensive to produce.

Gray Iron and Ductile Iron Castings

Paper runners are ideal for iron casting processes, such as gray iron or ductile iron, which involve high pouring temperatures and require precise control of metal flow to avoid defects like cold shuts or misruns.

Green Sand Molding

In the green sand molding process, paper casting runners help ensure a controlled metal flow, even in complex and intricate mold designs. Their adaptability and ease of integration make them a preferred choice for many foundries working with sand molds.

Benefits of Paper Casting Runners

The use of paper casting runners offers several advantages, making them an increasingly popular choice in modern foundries:

Cost-Effectiveness

Paper casting runners are significantly less expensive to produce compared to metal counterparts. The materials used for paper runners are readily available, and the production process is less resource-intensive, resulting in lower overall costs for foundries.

Environmental Sustainability

As environmental concerns continue to grow in the manufacturing industry, paper casting runners provide an eco-friendly alternative to traditional metal gating systems. Paper is biodegradable and recyclable, reducing the environmental impact of the foundry operations. Additionally, their use can help foundries meet sustainability goals by minimizing waste.

Lightweight and Easy to Handle

Paper runners are much lighter than metal runners, making them easier to handle, transport, and install in casting systems. This reduces manual labor and improves the overall efficiency of the casting process. Their lightweight nature also allows for easier modifications to the gating system as needed.

Enhanced Flow Control

The paper material used in these runners is designed to provide better control over the flow of molten metal. By offering greater flexibility in mold design and runner configuration, paper runners can help prevent common issues such as cold shuts, misruns, and air entrapment.

Improved Casting Quality

The use of paper runners in gating systems can result in smoother and more consistent metal flow into molds. This helps improve casting quality by reducing defects and ensuring better surface finishes on cast parts. Additionally, the runners’ ability to absorb heat more quickly reduces the risk of thermal stresses during solidification.

Design Principles of Paper Casting Runners

Effective design of paper casting runners requires a deep understanding of the casting process, the properties of the molten metal, and the mold configuration. The following principles should be considered when designing paper casting runners:

Flow Rate Control

It is essential to design the paper runner system to match the flow rate requirements of the molten metal. The dimensions of the runners—such as width, height, and length—should be optimized based on the size of the mold and the flow characteristics of the metal being used. For instance, heavier metals like iron may require larger runners to ensure smooth flow into the mold cavity.

Heat Resistance

Since paper casting runners are exposed to high temperatures during the casting process, the paper material used must be capable of withstanding the heat without degrading. Specialized heat-resistant coatings or treatments are often applied to enhance the runner’s performance in high-temperature environments.

Mold and Runner Integration

The design of the paper runner system must seamlessly integrate with the mold design. Factors such as gating locations, riser placement, and mold filling speed should all be considered to ensure that the paper runner enhances the overall casting process. Customization of the runner design may be necessary for complex molds.

Minimizing Waste

An important design goal is to minimize waste during the casting process. This can be achieved by ensuring that the paper runner system is accurately sized and positioned to prevent excess material from being used. The ability to easily adjust the design of paper runners provides a significant advantage in reducing unnecessary waste.

Structural Integrity

While paper casting runners are lightweight, they still need to have sufficient structural integrity to support the weight and pressure of molten metal. Proper design and material selection ensure that the runner maintains its strength throughout the casting process, preventing breakage or distortion.

Challenges and Limitations of Paper Casting Runners

While paper casting runners offer numerous advantages, there are some challenges to consider:

-

High-Temperature Limitations

Paper casting runners are not suitable for all casting applications, particularly those involving extremely high-temperature metals like aluminum. They are best used in casting applications with metals such as iron, steel, and other materials that do not exceed the heat tolerance of the paper material. -

Durability in High-Pressure Systems

In high-pressure or high-volume casting systems, paper casting runners may face durability challenges, especially if subjected to mechanical stresses. In such cases, a combination of materials may be required to ensure the integrity of the gating system. -

Handling and Installation

Although paper runners are lighter, they require careful handling during installation to avoid damage. Ensuring proper setup is essential for optimal performance.

Conclusion

Paper casting runners represent a significant step forward in the evolution of gating systems for iron casting applications. Their affordability, environmental benefits, and ability to enhance casting quality make them an appealing option for many foundries, especially those focused on sustainable manufacturing practices. By following sound design principles and understanding the applications and limitations of paper runners, foundries can improve their casting processes, reduce waste, and achieve higher-quality products.

As the technology continues to evolve, it’s likely that paper casting runners will play an increasingly important role in the foundry industry, offering both economic and environmental benefits while ensuring precise and efficient casting results.