In aluminum casting, the quest for flawless components is often compromised by non-metallic inclusions—oxides, slag, and refractory particles. These impurities are primary culprits behind porosity, reduced mechanical strength, and increased scrap rates. While molten metal filtration is a recognized solution, its effectiveness hinges on one critical decision: selecting the correct filter mesh size.

An improperly chosen mesh can lead to either inadequate filtration or restricted metal flow, causing misruns. This guide, drawing on SF-Foundry’s expertise, will help you navigate this crucial selection to optimize your casting quality and yield.

Why Mesh Size Matters: The Science of Sieving

A fiberglass filter mesh acts as a two-dimensional sieve. Its openings, or mesh size, determine the size of inclusions it can physically trap. The principle is straightforward:

-

Mesh too large: Inclusions pass through, defeating the purpose.

-

Mesh too small: Even desirable fine particles and the metal flow itself are hindered, increasing turbulence and the risk of cold shuts or misruns.

For aluminum alloys, which rapidly form surface oxides, the goal is to efficiently remove these oxide skins and other coarse inclusions without affecting the healthy metal flow.

The SF-Foundry Selection Guide: Matching Mesh to Your Application

The optimal mesh size is not a universal number; it depends on your specific casting requirements. The following table provides a clear starting point for selection based on common application scenarios:

| Application Scenario | Recommended Mesh Size | Target Inclusion Size | Typical Casting Examples |

|---|---|---|---|

| General Purpose, Thick-Section Castings | 1.5 x 1.5 mm | Coarse oxides, slag lumps | Engine blocks, housings, structural brackets |

| Quality Castings with Surface Finish Requirements | 1.2 x 1.2 mm | Moderate to coarse inclusions | Automotive wheels, pump housings, manifold bodies |

| Thin-Wall & Precision Castings | 1.0 x 1.0 mm | Fine to moderate oxides | Electronic enclosures, aerospace components, heat sinks |

| High-Integrity, Aerospace, or Rotational Parts | 0.8 x 0.8 mm | Very fine inclusions | Impellers, aircraft structural parts, high-leakage-resistance components |

Key Considerations:

-

Alloy Type: More fluid alloys can sometimes utilize a finer mesh than less fluid ones.

-

Gating System Design: A well-designed, pressurized system can accommodate a slightly finer mesh with less flow impact than an unpresurized one.

-

Pouring Temperature: Standard aluminum pouring temperatures (typically 700°C – 750°C) are well within the working range of high-silica fiberglass filters.

Beyond the Mesh: Best Practices for Optimal Performance

Choosing the right size is the first step. Proper implementation is what delivers results.

-

Correct Placement: The filter should be placed in a turbulence-free zone, typically at the entrance to the sprue or in the runner system, ensuring it is fully covered by metal during the pour.

-

Adequate Preheat: While not as critical as for ceramic filters, a quick preheat with a torch removes moisture and reduces thermal shock.

-

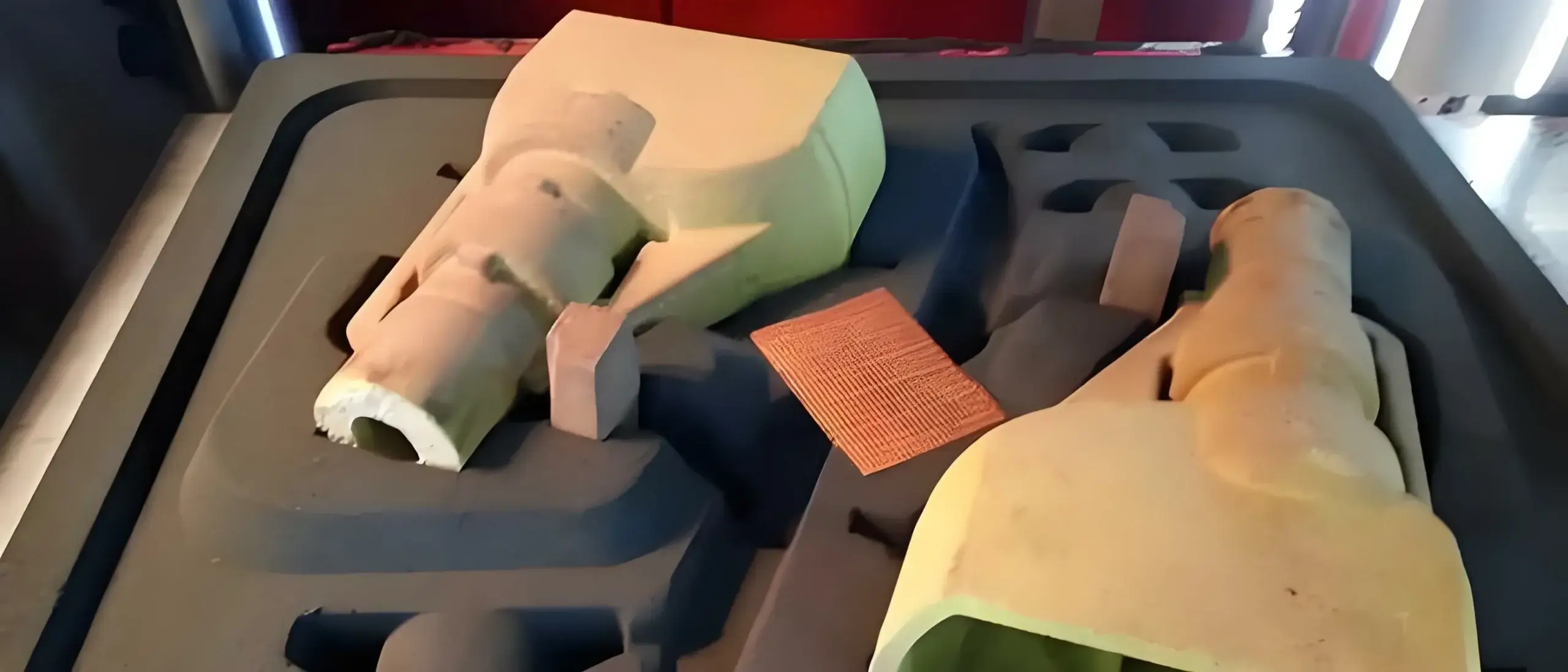

Secure Fit: The filter must be held securely in the mold or gating system to prevent displacement by the flowing metal. SF-Foundry filters can be easily cut and shaped for a perfect fit.

-

Monitor Flow Rate: Observe the first castings. If the metal front appears sluggish or the mold doesn’t fill completely, the mesh may be too fine for your current gating design.

The SF-Foundry Advantage

At SF-Foundry, we don’t just sell filters; we provide filtration solutions. Our high-silica fiberglass filter meshes are engineered for exceptional thermal stability and minimal metal interaction, ensuring they capture impurities without altering your alloy chemistry.

Still Unsure? Let Our Experts Help.

Selecting the perfect mesh is a balance of science and practical experience. For a personalized recommendation based on your specific alloy, part geometry, and gating design, contact the SF-Foundry technical team today. We are committed to helping you achieve cleaner metal, fewer defects, and higher profitability.

→ Request a free sample kit to test different mesh sizes in your foundry.