In the world of metal component manufacturing, the choice of casting process often boils down to a fundamental decision between flexibility and efficiency. As specialists at SF-Foundry, we work closely with foundries navigating this exact choice: Permanent Mold Casting versus Sand Casting. One utilizes a reusable metal tool to achieve consistency, while the other employs a disposable sand mold to maximize design freedom. Understanding their distinct advantages, limitations, and ideal applications is critical for optimizing cost, quality, and lead time for your project. This guide draws on our direct experience to provide a clear, actionable comparison.

Permanent Mold Casting vs. Sand Casting: Core Differences

The table below summarizes the essential contrasts between these two foundational processes.

| Feature | Permanent Mold Casting (Gravity/Die) | Sand Casting |

|---|---|---|

| Mold Type | Reusable metal mold (cast iron, steel). Used for hundreds to thousands of cycles. | Expendable sand mold. A new mold is created for every casting. |

| Pattern Requirement | Requires a master pattern to create the permanent mold. High initial cost and lead time. | Requires a reusable pattern (wood, metal, plastic) for every mold. Lower initial cost. |

| Production Scale | Best for medium to high-volume production to amortize mold cost. | Excellent for low-volume runs, prototypes, and single large parts. |

| Part Quality & Finish | Good to excellent surface finish, tight dimensional tolerances, and uniform microstructure due to rapid cooling. | Rough surface finish (sand texture), wider tolerances requiring machining allowance. |

| Mechanical Properties | Generally higher strength and density due to faster cooling and finer grain structure. | Properties can be excellent but are more variable; cooling rate is slower. |

| Lead Time for Parts | Longer initial lead time for mold fabrication. Very short cycle time once in production. | Short initial lead time. Longer per-part cycle time due to mold-making for each piece. |

| Cost Structure | High initial tooling cost, low variable cost per part. | Low initial tooling cost, higher variable cost per part (mold labor & materials). |

| Design Complexity | Limited by need to eject from a rigid metal mold. Undercuts are challenging. | Extremely high freedom. Can produce virtually any geometry, including complex internal passages with sand cores. |

| Common Materials | Primarily non-ferrous alloys: Aluminum, Magnesium, Copper-based alloys. Some cast iron. | All castable metals, including ferrous (iron, steel) and non-ferrous. |

| Best For | High-integrity parts needing good finish at medium/high volume (auto wheels, gear housings). | Large parts, complex geometries, prototypes, and low-volume production of any metal. |

Deep Dive: Understanding Each Casting Process

Permanent Mold Casting

In this process, molten metal is poured (by gravity or low pressure) into a preheated metal mold. The key is the mold’s reusability, which drives efficiency and consistency over a production run.

Key Insight from Our Experience: The performance of a permanent mold process hinges on mold life and metal quality. Thermal cycling causes wear. Our role is to extend mold life and ensure clean fills. We recommend and supply:

-

-

High-Performance Mold Coatings: These ceramic-based coatings are sprayed onto the mold cavity. They are not optional; they provide a thermal barrier to control solidification, prevent soldering (metal sticking to the mold), and dramatically improve the as-cast surface finish.

-

Ceramic Foam Filters (CFF): Used in the gating system of gravity-poured molds, they are essential for trapping oxides and inclusions, ensuring only clean metal enters the cavity. This prevents defects and protects the mold surface from erosion.

-

Feeder Sleeves & Insulation: For optimizing feeding and reducing shrinkage defects in thicker sections.

-

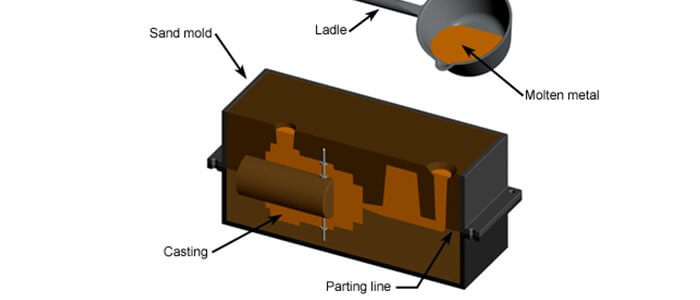

Sand Casting: The Champion of Flexibility

Sand casting involves creating a mold from compacted sand, using a pattern to form the cavity. The mold is destroyed to remove the casting. The most common variant is Green Sand Casting (moist clay-bonded sand).

-

Key Insight from Our Experience: Success in sand casting is defined by mold strength and metal cleanliness. A weak mold leads to defects like sand inclusions; dirty metal compounds the problem. Our solutions target both:

-

Mold and Core Coatings: Applied to the sand surface, these refractory paints create a hard, smooth barrier. This prevents metal penetration (where metal seeps into sand pores) and sand erosion/wash, which are primary causes of sand inclusions and poor surface finish.

-

Advanced Filtration: Just like in permanent mold, filters are critical. A Ceramic Foam Filter or a Cellular Filter placed in the runner system captures slag, dross, and loose sand that has eroded from upstream mold sections, preventing it from entering the casting cavity. As we always advise clients: A filter is a vital safety net, but it is not a substitute for good sand practice and proper mold coating.

-

Binder Additives: We provide materials that improve sand cohesion, reducing friability—a common root cause of loose sand in molds.

-

Permanent Mold Casting vs. Sand Casting: How to Choose

Use these questions to guide your selection:

What is your production volume?

-

-

Low Volume (< 500 parts) or Prototypes: Sand Casting is almost always the economical choice due to minimal tooling cost.

-

Medium to High Volume (1,000 – 50,000+ parts): Permanent Mold Casting becomes viable and often superior, as the higher tooling cost is spread over many parts, lowering the unit price.

-

What are your part quality requirements?

-

-

Need a good surface finish (125-250 µin Ra) and tight tolerances with minimal machining? Choose Permanent Mold.

-

Is a rough finish acceptable, and can you accommodate machining stock? Sand Casting is suitable.

-

How complex is your part geometry?

-

-

Extremely complex with internal passages, undercuts, or organic shapes? Sand Casting (with cores) offers unmatched freedom.

-

A part that can be ejected from a two-part metal mold? Permanent Mold is a strong candidate.

-

What material are you using?

-

-

Aluminum, Magnesium, or Copper-based alloys? Both processes are excellent; let volume and geometry decide.

-

Cast Iron, Steel, or other high-temperature alloys? Sand Casting is the standard and often the only practical option.

-

Partnering with SF-Foundry for Optimal Results

Regardless of your chosen process, achieving defect-free castings requires control over the mold-metal interface and metal cleanliness.

-

For Permanent Mold Casters: We help you protect your capital investment in tooling. Our coatings extend mold life by thousands of cycles, while our filtration systems ensure each pour yields a sound, saleable part.

-

For Sand Foundries: We provide the integrated defense system against your most common rejects. From coatings that create a perfect mold surface to filters that catch erosion sand, our products work together to solve the core challenges of sand casting.

Choosing between permanent mold and sand casting is not about which is “better,” but which is right for your specific part, volume, and budget.

Need an expert opinion on the optimal process for your component design?

Contact SF-Foundry. Our technical team can review your drawings and requirements, offering unbiased advice on process selection and the material solutions—be it coatings, filters, or binders—that will ensure quality and cost-efficiency from your first sample to full production.