When I first started working in industrial filtration over a decade ago, the foam versus honeycomb filter debate seemed like a theoretical engineering discussion. That changed when I visited a foundry struggling with persistent casting defects. They were using a standard filtration method, but microscopic inclusions were still ruining their high-precision components. We analyzed the issue—turbulent metal flow trapping oxides and slag—and switched to a specialized ceramic foam filter with a specific pore gradient. The defect rate dropped by over 70%. That hands-on experience cemented my understanding: the choice between foam and honeycomb isn’t academic; it’s a critical, practical decision that directly impacts product quality, efficiency, and cost.

This guide will break down the key differences between these two filter types, with insights tailored for demanding fields like metalcasting, to help you select the optimal solution.

The Fundamental Difference: Structure Dictates Function

At their core, foam and honeycomb filters are opposites in architecture, defining their entire behavior.

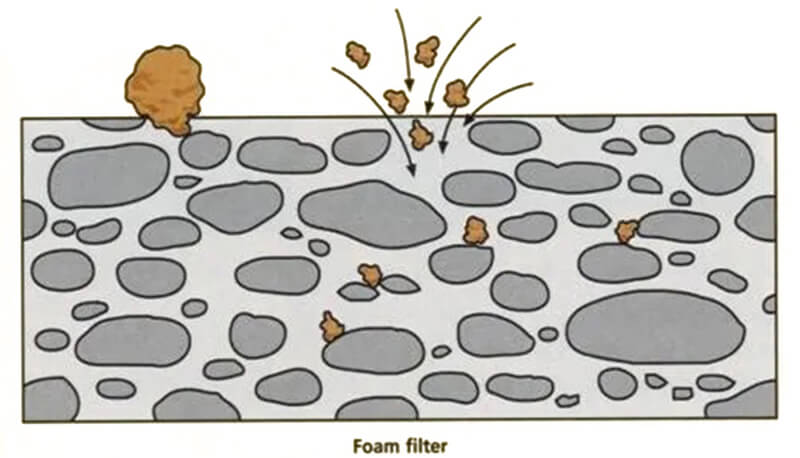

Foam Filters feature a three-dimensional, stochastic network of interconnected pores. Imagine a chaotic labyrinth where pathways are random, tortuous, and vary in size. This complex, open-cell structure is intrinsic to materials like polyurethane or ceramic foam.

Honeycomb Filters are engineered for order. They consist of many parallel, straight channels arranged in a uniform hexagonal grid, much like a beehive. These channels are often plugged at alternate ends, creating a “wall-flow” design that forces fluid through the porous channel walls. This structure is monolithic and precise, typically made from ceramic, metal, or composite materials.

Performance Comparison: A Detailed Breakdown

The structural clash leads to a clear divergence in performance. Here’s how they stack up on critical operational metrics.

| Feature | Foam Filter | Honeycomb Filter | Impact on Your Application |

|---|---|---|---|

| Filtration Mechanism | Depth Filtration: Particles are captured throughout the entire 3D thickness of the material, deep within the pore matrix. | Surface/Wall-Flow Filtration: Particles are intercepted on the surface of the channel walls or within their controlled porosity. | Depth filtration excels at loading large amounts of contaminant; wall-flow provides a sharper, more consistent particle size cutoff. |

| Pressure Drop (ΔP) | Generally Higher. The chaotic flow path creates significant resistance as fluid navigates the random pores. | Generally Lower & Stable. Straight inlet channels minimize flow resistance; pressure builds gradually as the wall cakes. | Lower initial ΔP in honeycombs means higher energy efficiency. Foam filters may require more pumping power. |

| Filtration Efficiency | Good for a broad particle range, but efficiency can vary with pore size distribution and loading. | Exceptionally High and Predictable. Precise control over channel size and wall porosity allows for targeted, reliable efficiency. | For applications demanding guaranteed purity (e.g., protecting catalysts, achieving emission specs), honeycombs are often mandatory. |

| Dirt Holding Capacity | Very High. The entire sponge-like volume can absorb and trap contaminants throughout its depth. | Moderate. Contaminants collect primarily on the channel walls, limiting total storage volume before clogging occurs. | High capacity means longer service life and lower maintenance frequency—a key advantage for foam in pre-filtration or batch processes. |

| Mechanical & Thermal Strength | Moderate; can be brittle (ceramic foam) or flexible (PU). Thermal shock resistance varies by material. | Very High. The monolithic, regular structure offers superior crush strength and thermal durability, especially in ceramics. | In high-vibration, high-temperature, or high-pressure environments (like exhaust systems), honeycomb integrity is often unmatched. |

Material and Application Spotlight of Foam vs Honeycomb Filter

Foam Filter Materials & Dominant Applications:

Polyurethane (PU) Foam: Used for cost-effective, washable filters in aquaculture, compressor intake air, and low-duty liquid filtration.

Ceramic Foam (e.g., Zirconia, Alumina Silicate): The star of extreme processes. This is where foundry applications come to the forefront. Ceramic foam filters (CFFs) are indispensable in investment casting and sand casting of aluminum, iron, steel, and superalloys. Their random 3D network excels at trapping non-metallic inclusions (slag, oxides) while withstanding the thermal shock of 1600°C+ molten metal. Their depth filtration allows for high metal throughput with effective cleaning.

Honeycomb Filter Materials & Dominant Applications:

-

Cordierite & Silicon Carbide (SiC) Ceramic: The backbone of automotive emissions control (catalytic converters, DPFs). Their strength and thermal properties are ideal.

-

Metallic Alloys: Used in aerospace and power generation for high-temperature gas filtration.

-

Filter Paper/Composites: Form the core of panel air filters in vehicles and HVAC.

-

In foundry contexts, while less common than foam, dense ceramic honeycombs are sometimes employed for specialized gating systems or where a very controlled, laminar metal flow is required ahead of a foam filter, demonstrating how the technologies can be complementary.

Foundry-Specific Analysis: Molten Metal Filtration Performance

In metalcasting, the choice is paramount. Here’s a direct comparison for this critical industry:

-

Ceramic Foam Filters (CFFs): These are the industry standard for most metal filtration. The random, tortuous pore structure is exceptionally effective at arresting fine inclusions through deep-bed filtration and promoting laminar, non-turbulent metal flow, which reduces re-oxidation. They are the preferred choice for high-quality, complex castings where metal cleanliness is non-negotiable.

-

Ceramic Honeycomb Filters: These feature straight, parallel channels and act more as a sieve or strainer. They are highly effective for removing larger chunks of refractory or slag and offer very high flow rates with low initial resistance. Their use is often specific to certain ferrous foundry practices or as part of a multi-stage filtration system.

The Verdict for Foundries: For comprehensive cleaning of molten aluminum, iron, or steel, Ceramic Foam Filters are overwhelmingly chosen for their superior depth filtration and flow-control benefits. The honeycomb’s straight-path design is less effective at trapping micron-sized inclusions and can even promote turbulent jetting if not carefully designed.

![]()

Foam vs Honeycomb Filter: How to Make the Right Choice?

Stop thinking about which filter is “better.” Start by diagnosing your system’s primary challenge.

Select a FOAM Filter if your top priority is:

-

High Dirt Holding Capacity & Extended Service Life (e.g., water treatment, pre-filtration).

-

Effective Depth Filtration of fluids with a wide particle size distribution.

-

Promoting Flow Distribution & Mixing (as a pre-filter or sparger).

-

Molten Metal Filtration in foundries for superior inclusion capture and improved metal flow.

Select a HONEYCOMB Filter if your top priority is:

-

Precision, High-Efficiency Filtration with a stable, predictable pressure drop (e.g., final-stage hydraulic filters, air purifiers).

-

Minimizing System Energy Consumption (low ΔP is critical).

-

Withstanding Extreme Mechanical/Thermal Stress (exhaust systems, hot gas filters).

-

Providing a Substrate for Catalytic Reactions (emissions control).

Pro Insight: The Synergistic System

The most robust solutions often combine both. A common and effective setup, especially in critical applications, uses a foam filter upstream as a “workhorse” to remove the bulk of contaminants and protect the more sensitive and expensive honeycomb filter downstream, which performs the final “polishing.” This layered approach maximizes overall system life, efficiency, and cost-effectiveness.

Precision Filtration Solutions for Your Foundry from SF-Foundry

At SF-Foundry, we understand that the theoretical difference between foam and honeycomb filters gets tested every day in the harsh reality of the foundry floor. Our expertise isn’t just in supplying filters; it’s in providing the right filtration solution for your specific metal, casting method, and quality goals.

We manufacture and supply a comprehensive range of high-performance foundry filters, including:

-

Ceramic Foam Filters (CFFs): For superior depth filtration and flow control in aluminum, iron, steel, and copper-based alloys.

-

Honeycomb Filters: For applications requiring high flow-rate screening and slag removal.

-

Fiberglass Filter Meshes: For cost-effective, efficient filtration in non-ferrous foundries, particularly aluminum.

Let’s discuss your application. Tell us about the challenges you’re facing with inclusions, turbulence, or yield, and our team can help specify the optimal filter type, pore size, and placement for your gating system.