Fiberglass mesh for casting is an indispensable material in modern industrial applications, offering a unique combination of strength, flexibility, and corrosion resistance. As someone who has worked with composite materials for over a decade, I’ve witnessed firsthand how this remarkable reinforcement material has transformed manufacturing processes across multiple industries. Whether you’re involved in metal casting, composite fabrication, or industrial construction, understanding how to properly select and implement fiberglass mesh can significantly enhance your product quality and performance.

What is Fiberglass Mesh and Why Is It Crucial for Casting Applications?

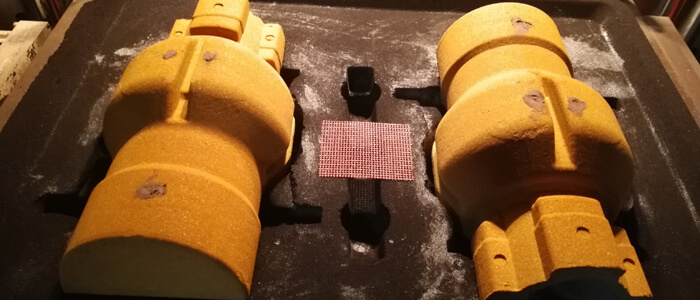

Fiberglass mesh is a woven material made from incredibly fine glass fibers, with a diameter typically between one-fifth to one-twentieth the thickness of a human hair. These fibers are woven into various grid patterns and often coated with specialized treatments to enhance their performance characteristics.

In casting processes, fiberglass mesh serves as a reinforcement material that:

-

Provides dimensional stability during curing and solidification

-

Enhances tensile strength and impact resistance

-

Reduces cracking and shrinkage in finished products

-

Improves durability and longevity of cast components

-

Distributes stress evenly throughout the cast part

The development of fiberglass manufacturing technology, particularly the breakthrough in tank furnace drawing methods pioneered by Chinese companies like Jushi Group, has made high-quality fiberglass mesh more accessible worldwide. This innovation broke decades of American technological monopoly in this field, revolutionizing the global availability of quality fiberglass products.

Key Properties and Technical Specifications of Casting-Grade Fiberglass Mesh

When selecting fiberglass mesh for casting applications, understanding its technical specifications is crucial for optimal performance. The material’s exceptional properties make it suitable for demanding industrial environments.

Mechanical Properties

Fiberglass mesh possesses outstanding mechanical characteristics that make it ideal for reinforcement:

-

High tensile strength: Despite its lightweight nature, fiberglass mesh provides exceptional resistance to pulling forces

-

Excellent flexibility: The material can conform to complex shapes and geometries without losing structural integrity

-

Low elongation: Fiberglass maintains dimensional stability under stress, with minimal stretching or deformation

-

Good fatigue resistance: It withstands repeated loading cycles without significant degradation

Thermal and Chemical Resistance

One of the key advantages of fiberglass mesh in casting applications is its performance in extreme conditions:

-

Thermal stability: Fiberglass maintains its properties across a wide temperature range, from sub-zero to elevated temperatures encountered in metal casting processes

-

Fire resistance: As an inorganic material, it doesn’t contribute to fire spread and can enhance the fire rating of composite structures

-

Corrosion resistance: Unlike metal reinforcements, fiberglass doesn’t rust or corrode when exposed to moisture, chemicals, or alkaline environments

Weight and Handling Characteristics

The physical characteristics of fiberglass mesh contribute to its ease of use:

-

Lightweight: With weights typically categorized as below 100g/m², 100-150g/m², and above 150g/m², fiberglass mesh adds minimal weight to finished components

-

Easy handling: The material can be easily cut, shaped, and positioned within molds

-

Compatibility: Fiberglass mesh works well with various resin systems, concrete, and other matrix materials

Applications of Fiberglass Mesh in Different Casting Processes

Based on my experience working with industrial manufacturers, I’ve seen fiberglass mesh implemented across diverse casting applications, each with specific requirements and considerations.

Composite Casting and Mold Making

In resin-based composite manufacturing, fiberglass mesh serves as primary reinforcement:

-

Wind turbine components: The wind energy sector represents the largest user of knitted fiberglass fabrics, where the material’s specific strength and stiffness make it ideal for massive turbine blades operating under extreme conditions

-

Marine applications: Boat hulls and deck structures benefit from fiberglass’s corrosion resistance in saltwater environments

-

Aerospace components: From homemade aircraft like Burt Rutan’s designs to commercial applications, fiberglass composites offer an excellent strength-to-weight ratio

-

Industrial components: Tanks, pipes, and covers utilize fiberglass reinforcement for chemical resistance and durability

Metal Casting Support

While not typically embedded in molten metal, fiberglass materials play supporting roles in foundry operations:

-

Insulation blankets: Fiberglass blankets control cooling rates in metal castings, promoting directional solidification and reducing defects

-

Reinforcement: In certain low-temperature metal casting applications, specialized fiberglass meshes can provide supplementary reinforcement

Construction and Architectural Element Casting

Fiberglass mesh finds extensive use in architectural concrete and resin castings:

-

Glass Fiber Reinforced Concrete (GFRC): The mesh reinforces thin concrete sections, preventing crack propagation

-

Architectural panels: Decorative and structural facade elements benefit from fiberglass reinforcement

-

Precast concrete elements: Manufacturing of concrete components with complex geometries utilizes fiberglass mesh for durability

Table: Fiberglass Mesh Selection Guide by Application

| Application | Recommended Mesh Weight | Key Performance Factors | Special Considerations |

|---|---|---|---|

| Wind Turbine Blades | Heavyweight (>150g/m²) | High tensile strength, fatigue resistance | Multi-axial fabrics for directional strength |

| Marine Components | Medium to Heavyweight (100-150g/m²) | Corrosion resistance, impact strength | Chemical compatibility with resin system |

| GFRC Architectural Elements | Light to Mediumweight (<100-150g/m²) | Alkali resistance, flexibility | Mesh openness for concrete penetration |

| Industrial Pipes/Tanks | Mediumweight (100-150g/m²) | Chemical resistance, dimensional stability | Compatibility with service environment |

Selecting the Right Fiberglass Mesh for Your Casting Project: A Practical Guide

Choosing the appropriate fiberglass mesh requires careful consideration of multiple factors. Through years of working with manufacturers, I’ve developed this framework for selection:

Understanding Mesh Specifications

-

Weight categories: Fiberglass mesh is typically classified by weight per square meter (<100g/m², 100-150g/m², >150g/m²), with heavier weights generally providing greater reinforcement

-

Weave pattern: The weaving method (plain weave, twill, satin, or knitted) affects flexibility, drapeability, and strength characteristics

-

Coating type: Special coatings like alkali-resistant treatments for concrete applications significantly enhance performance and longevity

-

Mesh openness: The size of openings in the mesh determines how well the matrix material penetrates and bonds with the reinforcement

Performance Requirements

-

Strength needs: Assess the mechanical demands of your application, including tensile, flexural, and impact strength requirements

-

Environmental conditions: Consider exposure to chemicals, moisture, UV radiation, and temperature extremes

-

Durability expectations: Evaluate the expected service life and maintenance requirements of the finished product

-

Regulatory compliance: Ensure the selected mesh meets industry-specific standards and certifications

Manufacturing Considerations

-

Compatibility with matrix materials: Verify chemical compatibility between the fiberglass mesh and your resin or concrete system

-

Process compatibility: Consider how the mesh will integrate with your specific manufacturing process, whether hand lay-up, infusion, or automated placement

-

Handling characteristics: Evaluate how easily the mesh can be cut, positioned, and consolidated within your mold or formwork

Advancements and Future Trends in Fiberglass Mesh Technology

The fiberglass reinforcement industry continues to evolve, driven by technological innovations and changing market demands. Staying informed about these developments can provide competitive advantages:

Manufacturing Innovations

Chinese manufacturers have made significant strides in fiberglass production technology, with companies like Jushi Group now commanding approximately 24% of the global fiberglass market. This represents a dramatic shift from decades of American and European dominance in this sector.

Market Growth and Diversification

Research indicates continued expansion of the global fiberglass reinforcements market, with steady growth projected through 2031. This growth is driven by:

-

Infrastructure development: Increasing use of fiberglass-reinforced composites in construction and civil engineering

-

Renewable energy expansion: Ongoing development of wind power infrastructure worldwide

-

Transportation lightweighting: Automotive and aerospace industries increasingly adopt fiberglass composites to reduce weight and improve efficiency

-

Industrial applications: Growing recognition of fiberglass advantages in corrosive environments and specialized equipment

Product Development Trends

-

Multi-axial fabrics: Knitted multi-axial fiberglass fabrics continue gaining popularity due to their superior mechanical properties and controlled anisotropy

-

Sustainable solutions: Development of eco-friendly sizing agents and recycling technologies for fiberglass products

-

Hybrid reinforcements: Combining fiberglass with other fibers like carbon or basalt to create optimized performance profiles

-

Smart manufacturing: Integration of Industry 4.0 technologies in fiberglass production, improving consistency and reducing costs

Best Practices for Working with Fiberglass Mesh in Casting Applications

Based on my hands-on experience, following these practical guidelines can significantly improve your results when working with fiberglass mesh:

Preparation and Handling

-

Proper storage: Keep fiberglass mesh in its original packaging until use to prevent contamination and moisture absorption

-

Cutting techniques: Use sharp scissors or rotary cutters to cleanly sever fibers without fraying edges

-

Surface preparation: Ensure mesh is clean and free of releases agents or contaminants that might affect adhesion

-

Personal protection: Wear appropriate PPE, including gloves and dust mask, when handling fiberglass materials

Installation and Implementation

-

Positioning in mold: Place mesh at the point of maximum tensile stress within the casting, typically away from neutral axis

-

Wet-out procedures: For resin systems, ensure complete saturation of fibers to maximize bond and eliminate dry spots

-

Consolidation: Remove air pockets and ensure intimate contact between mesh and matrix material

-

Layer management: For multiple layers, stagger joints and ensure full integration between plies

Quality Control and Troubleshooting

-

Inspection protocols: Implement regular checks for mesh placement, saturation, and consolidation

-

Common defect identification: Learn to recognize and address issues like fiber show-through, dry areas, or misalignment

-

Testing and validation: Conduct mechanical tests on sample castings to verify performance before full-scale production

Conclusion: Leveraging Fiberglass Mesh for Superior Casting Results

Fiberglass mesh for casting represents a versatile, cost-effective reinforcement solution that continues to evolve to meet industrial demands. From wind turbine blades that harness renewable energy to corrosion-resistant chemical tanks and architecturally striking GFRC facades, this material demonstrates remarkable versatility across applications.

The global fiberglass market has undergone significant transformation in recent decades, with expanded production capacity and technological advancements making high-quality reinforcement materials more accessible than ever. As manufacturing processes continue to refine and new applications emerge, fiberglass mesh remains a fundamental enabling technology for innovative casting applications across industries.

By understanding the properties, selection criteria, and implementation best practices outlined in this guide, you can make informed decisions about incorporating fiberglass mesh into your casting processes, ultimately producing stronger, more durable, and higher performance components for your specific applications.