Whether you’re designing custom air filters, maintaining industrial equipment, or building high-performance engines, selecting the right foam air filter material is critical to efficiency and longevity. As a trusted manufacturer and supplier of filtration solutions, SF-Foundry is here to help you navigate the options and source the best materials for your needs.

In this article, we’ll explore where to find quality foam filter media, what technical aspects to consider, and how to ensure your filters perform reliably.

Where to Buy Foam Air Filter Material

Online Marketplaces

Platforms like Amazon and eBay offer accessible options for small-scale purchases. Look for sellers providing detailed product descriptions including PPI (pores per inch), material type, and oil compatibility.

Specialist Automotive Retailers

Companies like Summit Racing and JEGS stock oiled foam sheets ideal for automotive and motorsport applications. These are often sold pre-cut for convenience.

Industrial Suppliers

For bulk orders or specific technical requirements, suppliers like McMaster-Carr, Grainger, or FilterBuy.com provide professional-grade foam with certified metrics.

Direct from Manufacturers

Partnering with a specialized foam filter manufacturer ensures consistency, customizability, and technical support—especially important for OEM or large-volume applications.

Key Specifications to Consider

- PPI (Pores Per Inch): Determines filtration granularity. Low PPI (10–30) suits pre-filters; medium (30–60) is ideal for primary filters; high PPI (60–90+) offers fine filtration.

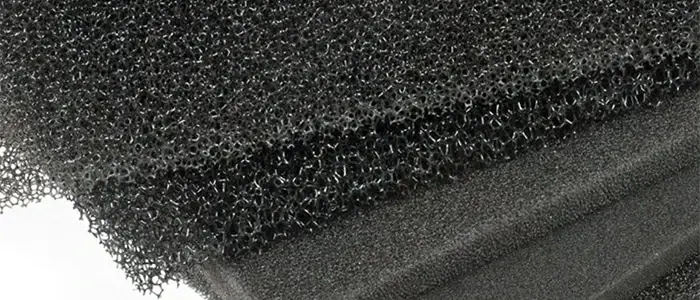

- Open-Cell Structure: Ensures airflow while capturing contaminants. Avoid closed-cell foam, which restricts air passage.

- Material Composition: Polyurethane is most common for its durability and oil-retention properties.

- Oiled vs. Dry Media: Oiled foam enhances particle adhesion in engine filters, while dry foam is typical for HVAC or light-duty applications.

Applications and Compatibility

- Automotive Filters: Use oiled, open-cell foam (30–60 PPI) for intake filters.

- HVAC Systems: Dry, finer foam (40–60 PPI) works best to capture dust without restricting airflow.

- Industrial Machinery: Select foam based on environmental contaminants and airflow requirements.

- Small Electronics: Lightweight, low-resistance dry foam is sufficient.

Why Partner with Specialized Foam Filter Manufacturers?

- Customizable Solutions: Foam material tailored to your size, PPI, and application requirements.

- Technical Guidance: Help with selection, integration, and maintenance.

- Quality Assurance: Consistent, high-performance materials compliant with international standards.

- Bulk and OEM Supply: Reliable logistics and pricing for large-volume orders.

Conclusion

Choosing the right foam air filter material impacts the performance and lifespan of your equipment. Whether you source from mainstream retailers or work directly with manufacturers, always prioritize technical specifications over price alone.

For specialized needs or large-volume orders, consider partnering with an experienced supplier like SF-Foundry. We offer tailored solutions and expert support to keep your systems running cleanly and efficiently.