In the pursuit of superior casting quality, foundries worldwide rely on a critical yet often underestimated component: the fiberglass mesh filter. This specialized filtration solution plays a pivotal role in ensuring metal purity, directly impacting the mechanical properties and defect rate of final castings. Unlike standard air filters, foundry-grade glass fiber filters are engineered to withstand extreme temperatures and harsh conditions of metal pouring processes.

At SF-Foundry, with over 20 years of expertise in supplying foundry consumables, we understand the nuanced challenges faced by modern foundries. This article provides a professional, in-depth look at fiber glass mesh filters, offering insights grounded in practical experience and technical knowledge.

What Are Foundry Fiberglass Mesh Filters?

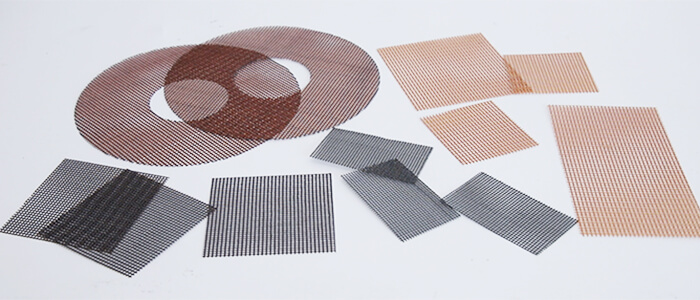

Fiberglass mesh filters for foundry are precision-woven meshes made from high-temperature resistant glass fibers, specifically designed for filtering molten metals. These filters are chemically treated with binders to enhance their thermal shock resistance and structural integrity upon contact with molten metal.

Key Characteristics:

-

High-Temperature Resistance: Crafted from high-silica glass compositions, these foundry filters can withstand short-term exposure to temperatures exceeding 900°C – 1700°C, making them suitable for aluminum, iron, steel, and non-ferrous applications.

-

Mechanical Sieving Action: They function primarily by mechanically trapping inclusions such as slag, sand, and oxides within their intricate mesh network.

-

Rigid yet Brittle Nature: They offer excellent rigidity for easy installation but cannot be handled roughly.

Key Benefits for Your Foundry Operation

Integrating glass fiber filters into your gating system delivers tangible operational and quality advantages:

Improved Casting Quality and Reduced Defects:

-

-

Efficient Inclusion Removal: Effectively captures non-metallic inclusions (e.g., slag, oxide films, sand particles), drastically reducing defects like slag holes and sand inclusions.

-

Enhanced Mechanical Properties: Cleaner metal translates to improved and more consistent tensile strength, elongation, and impact resistance in final castings.

-

Superior Machinability: By eliminating hard inclusions, tool wear during machining is significantly reduced, lowering secondary processing costs.

-

Optimized Pouring Process & Yield Improvement:

-

-

Laminar Flow Promotion: The filter calms turbulent metal flow, minimizing air entrapment and secondary oxidation. This results in smoother filling and fewer gas-related defects.

-

Simplified Gating Design: Often allows for more compact and simpler gating systems, saving molding sand and space within the flask.

-

Increased Yield Rate: The significant reduction in scrap and rework rates leads to higher overall productivity and cost savings, offering an excellent return on a minimal investment.

-

Technical Specifications & Selection Guide

Choosing the right filter is crucial for success.

Standard Sizes: Commonly supplied in squares and round shapes, cut the size according to your needs, like ½” x ½” (12.7×12.7mm), ¾” x ¾”, 20x20mm, 23x23mm, and 17x17mm.

Mesh Size (Aperture):

-

-

Coarse Mesh (~1.5mm): Ideal for large iron and steel castings, offering high flow capacity.

-

Medium Mesh (~1.2mm): The universal choice for most gray iron, ductile iron, and steel applications.

-

Fine Mesh (~0.8mm): Recommended for non-ferrous metals (Al, Cu alloys) and high-precision castings requiring exceptional metal cleanliness.

-

Selection Criteria:

-

Alloy Type: Match the filter’s heat resistance to the pouring temperature (e.g., finer meshes for lower-temperature Al alloys).

-

Casting Size & Weight: Larger pours require filters with larger open area or coarser mesh to maintain adequate flow rate.

-

Inclusion Load: Heavily oxidized metal or sand system issues may necessitate a coarser mesh to prevent premature clogging.

Proper Installation and Handling Best Practices

Location: Install securely in the horizontal runner, ensuring all metal flowing into the mold cavity passes through the filter.

Method: The filter should be snugly fitted into a pre-cut slot in the sand mold. The sand itself must support the filter’s edges to prevent mechanical failure under metal pressure. Avoid using damaged filters.

Glass Fiber vs. Alternative Filter Technologies

| Feature | Glass Fiber Filter | Honeycomb Ceramic Filter | Ceramic Foam Filter |

|---|---|---|---|

| Cost | Most Economical | Higher | Highest |

| Filtration Mechanism | Primary: Mechanical | Depth, Adsorption | Depth, Mechanical |

| Flow Rate | Good | Reduces flow | Most controlled flow |

| Ideal For | Wide range: Aluminum, Iron, Steel, Non-Ferrous | High-value steel, Ductile iron | Critical aerospace/auto castings |

Conclusion

The implementation of high-quality fiberglass mesh filtration is one of the most cost-effective strategies for any foundry aiming to enhance quality, reduce scrap, and improve profitability. This mature technology provides a reliable first line of defense against costly inclusion defects.

Partnering with a knowledgeable supplier is key to maximizing these benefits. At SF-Foundry, we don’t just supply products; we provide technical support and expertise to help you select the optimal filtration solution for your specific needs.

Contact us today to discuss how our foundry fiberglass mesh filters can be integrated into your process to achieve a new level of casting excellence.