As the global foundry industry evolves, manufacturers face increasing pressure to improve efficiency, reduce costs, and meet stringent environmental regulations. This has sparked intense debate between traditional ceramic gating systems and innovative paper gating systems.

This comprehensive comparison examines both technologies across performance, cost, sustainability, and operational efficiency to help foundries make informed decisions for their specific needs.

Gating Systems Material Properties and Performance

Ceramic Gating Systems

- Temperature Resistance: Withstands extreme temperatures (up to 1750°C)

- Structural Integrity: Rigid but brittle – prone to cracking during handling

- Thermal Shock Resistance: Moderate – requires preheating for some applications

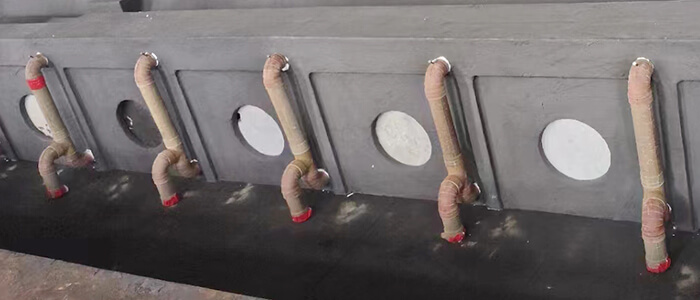

Paper Gating Systems

- Temperature Resistance: Stable up to 1600°C (sufficient for most ferrous casting)

- Structural Integrity: Flexible yet durable – resistant to impact damage

- Thermal Shock Resistance: Excellent – no preheating required

Key Insight: While ceramics tolerate higher temperatures, modern paper systems meet requirements for >90% of casting applications.

Operational Efficiency Comparison

| Factor | Ceramic Systems | Paper Systems |

|---|---|---|

| Installation Time | 30-50% longer | Rapid deployment |

| Worker Fatigue | High (heavy components) | Minimal (lightweight) |

| Customization | Limited (pre-set sizes) | Fully customizable |

| Breakage Rate | 5-8% | <1% |

Data Point: Foundries report 40% faster mold assembly when switching to paper gating systems.

Economic Impact Analysis

Labor: Paper systems reduce installation labor by 35-45%

Waste Handling: Ceramic disposal costs 3-5x more than biodegradable paper

Defect Reduction: Paper systems show 15-25% fewer casting defects

Environmental Compliance

Ceramic Systems Challenges

-

Non-recyclable waste (landfill requirements)

-

High energy production (1400-1600°C kiln temperatures)

-

Silica dust exposure risks

Paper Systems Advantages

-

100% biodegradable components

-

60% lower carbon footprint

-

No hazardous byproducts

-

Improves reclaimed sand quality

Regulatory Note: Paper systems help meet:

-

EU’s Industrial Emissions Directive

-

China’s Blue Sky Initiative standards

-

EPA Clean Air Act requirements

Application-Specific Recommendations

When to Choose Ceramic Gating Systems:

-

Superalloy casting (nickel/ cobalt-based)

-

Extremely large castings (>5 ton pours)

-

Specialty applications requiring >1650°C

When Paper Gating Systems:

-

Automotive components (80% of applications)

-

General machinery castings

-

High-volume production foundries

-

Facilities with sustainability commitments

Conclusion: Making the Right Choice

For most modern foundries, paper gating systems deliver:

✔ Better economics

✔ Superior operational efficiency

✔ Stronger environmental compliance

✔ Competitive technical performance

While ceramic systems retain niche applications, the industry is clearly moving toward paper-based solutions as the new standard.

Ready to upgrade your gating system? Contact our engineering team today for a free process evaluation. We offer standard configurations and custom solutions.