Silicon carbide (SiC), also known as carborundum, is an extremely hard synthetic compound of silicon and carbon that has become indispensable in modern industry. With its unique combination of properties including extreme hardness, high thermal conductivity, chemical inertness, and semiconductor characteristics, silicon carbide finds applications across numerous industries. This article explores the diverse uses of this remarkable material.

Understanding Silicon Carbide

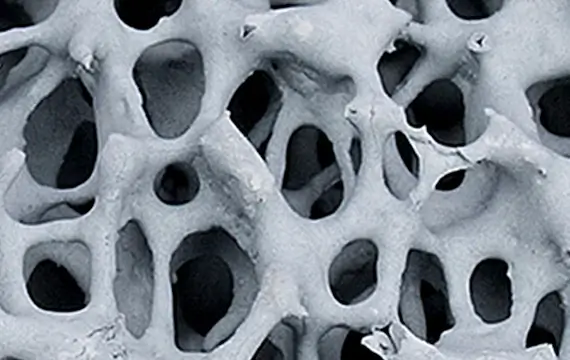

Before examining its uses, it’s important to understand what is silicon carbide. Silicon carbide (chemical formula SiC) is a compound of silicon and carbon that occurs naturally only in minute quantities as the mineral moissanite. Most silicon carbide used commercially is synthetically produced. The silicon carbide structure consists of tetrahedra of carbon and silicon atoms with strong bonds in the crystal lattice, giving it exceptional properties.

![]()

Key characteristics that make silicon carbide valuable include:

- Extreme hardness (Mohs scale 9.5)

- High silicon carbide melting point (~2700°C)

- Excellent thermal conductivity

- Chemical resistance

- Semiconductor properties

Industrial Abrasives and Cutting Tools

One of the primary uses for silicon carbide is in abrasive applications. The extreme hardness of this sic material makes it ideal for:

- Silicon carbide discs and wheels for grinding and cutting

- Silicon carbide powder for lapping and polishing

- Coated abrasives like sandpaper

- Wire sawing of silicon wafers and other hard materials

The uses of carborundum (another name for silicon carbide) in abrasives date back to its original discovery in 1891. Today, silicon carbide for sale in various grit sizes supports metalworking, stone cutting, and precision machining industries.

Silicon Carbide in Refractory and High-Temperature Applications

The exceptional thermal properties of silicon carbide make it valuable in high-temperature environments. Key silicon carbide applications in this category include:

- Kiln furniture for ceramic firing

- Burner nozzles

- Heat exchangers

- Components for metal and glass production

- Rocket nozzles and thermal protection systems

The silicon carbide material properties of high thermal conductivity combined with low thermal expansion make it resistant to thermal shock, crucial for many refractory uses.

Semiconductor and Electronic Applications

In the electronics industry, silicon carbide sic has become increasingly important due to its wide bandgap semiconductor properties. Major application of silicon carbide in electronics includes:

- Power electronics (diodes, MOSFETs)

- RF devices for telecommunications

- LED substrates

- Sensors for harsh environments

Compared to conventional silicon uses, sic silicon carbide devices can operate at higher voltages, temperatures, and frequencies while exhibiting lower energy losses.

Metallurgical Applications

In metallurgy, silicon carbide uses include:

- Deoxidizer in steel production

- Carburizing agent in iron foundries

- Additive in aluminum production

- Component in ceramic filters for metal casting

Comparison of Silicon Carbide with Other Materials

While uses of silicon in everyday life are well known, silicon carbide properties offer distinct advantages in demanding applications. Compared to standard silicon uses in everyday life, silicon carbide provides:

- Higher temperature capability

- Greater chemical resistance

- Better wear characteristics

- Superior high-power electronic performance

Conclusion

From traditional carborundum uses in abrasives to cutting-edge semiconductor applications, what is silicon carbide used for spans an impressive range of industries. As manufacturing processes improve and new applications are discovered, the silicon carbide uses continue to expand. Whether in the form of silicon carbide sheet, powder, or electronic wafers, this versatile material plays a critical role in modern technology and industry.

For those exploring silicon carbide for sale, it’s available in numerous forms including:

- Silicon carbide disk shapes for abrasives

- Silicon carbide discs for cutting tools

- Powder for metallurgical and refractory uses

- Wafers for semiconductor applications

The future of sic uses appears bright as researchers continue to unlock new potential applications for this remarkable material.