The demand for filter materials in the fields of metal casting, chemical production and environmental protection is growing. As an emerging high-performance filter material, alumina foam ceramic filters have gradually become an important part of the industrial field due to their excellent physical and chemical properties, environmental protection characteristics and broad application prospects. This article will explore the characteristics, preparation process and advantages of alumina foam ceramic filters in practical applications.

Characteristics of Alumina Foam Ceramic Filters

Alumina foam ceramic filter is a porous ceramic material made of alumina as the main raw material and prepared by a special process. Its notable features include:

1. High strength and high temperature resistance

Alumina materials have excellent mechanical strength and high temperature resistance, and can remain stable in environments up to 1200°C, so they are particularly suitable for filtering high-temperature metal melts, especially aluminum liquid.

2. Excellent chemical stability

Alumina foam ceramics have extremely high corrosion resistance and chemical stability. They are not easy to react chemically in acidic or alkaline environments and can maintain their filtration performance for a long time.

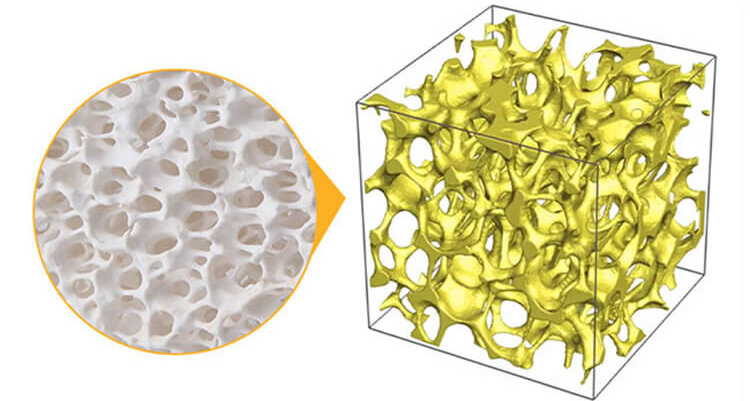

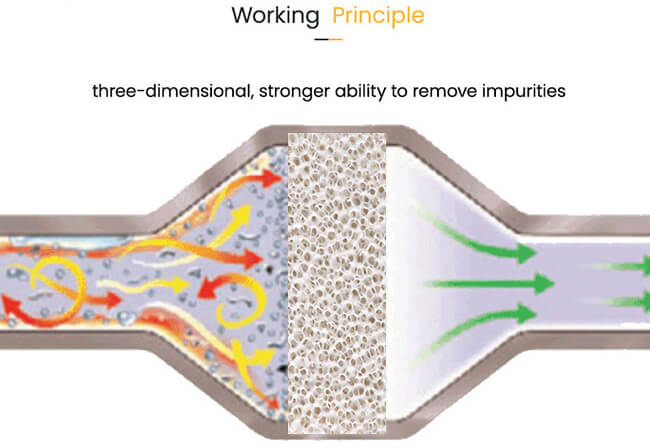

3. Unique foam structure

Its interior presents a three-dimensional interconnected porous structure with a large specific surface area and excellent air permeability, which helps to improve filtration efficiency and reduce fluid resistance.

4. Environmental protection and sustainability

As an inorganic material, alumina foam ceramics do not contain any components that are harmful to the environment and can be recycled, meeting modern environmental protection requirements.

Preparation process

The preparation of alumina foam ceramic filters usually adopts the following process steps:

1. Raw material preparation

Using high-purity alumina powder as the main raw material, a certain proportion of binder, foaming agent and additives are added to ensure that the material has good fluidity and molding properties.

2. Molding

The foam blank is made by foaming or impregnation. In the impregnation process, the polyurethane sponge is immersed in the ceramic slurry, and then extruded and dried to form a porous ceramic blank.

3. Sintering

The sintering process is carried out in a high-temperature furnace to remove organic components, and the ceramic particles are densified and sintered at high temperature, thereby obtaining a filter with high strength and durability.

Application fields

Alumina foam ceramic filters have been widely used in many industrial fields, and their main uses include:

1. Metal casting

In the casting industry, alumina foam ceramic filters are used to filter impurities and inclusions in metal melts, improve the quality of castings, and avoid the formation of defects such as pores and inclusions. In addition, its high temperature performance can meet the filtering needs of various metal melts such as aluminum, steel, and copper.

3. Chemical industry

In chemical production, the filter is used to support catalysts and filter and separate reactants. Its chemical stability and porous structure can improve reaction efficiency and product purity.

4. Environmental protection field

Alumina foam ceramic filters can be used in gas purification and wastewater treatment to effectively remove particulate pollutants and harmful chemicals. Its corrosion resistance enables it to maintain a long service life in harsh environments.

5. Energy and new materials field

In the energy industry, the filter is used for the separation of fuel cells and electrolytes; in the research and development of new materials, it also has extensive research value as a functional material.

Advantages and Development Prospects

Compared with traditional metal filters or organic filter materials, alumina foam ceramic filters have the following significant advantages:

- High efficiency: Its unique porous structure enables it to efficiently capture impurities and improve product quality.

- Long life: High temperature resistance and corrosion resistance make its service life far longer than other materials under harsh conditions.

- Green and environmentally friendly: Recyclable and reduce the generation of industrial waste.

With the continuous development of industrial technology and the increasing demand for high-performance filter materials, the market demand for alumina foam ceramic filters will continue to grow. In addition, its potential application prospects in emerging fields such as aerospace, biomedicine and new energy technologies have also attracted much attention.

Conclusion

Alumina foam ceramic filters are playing an important role in many fields with their excellent performance and wide applicability. In the future, with the further advancement of materials science and manufacturing processes, alumina foam ceramic filters will provide more innovative solutions for industrial production and environmental protection, and contribute to the promotion of sustainable development.