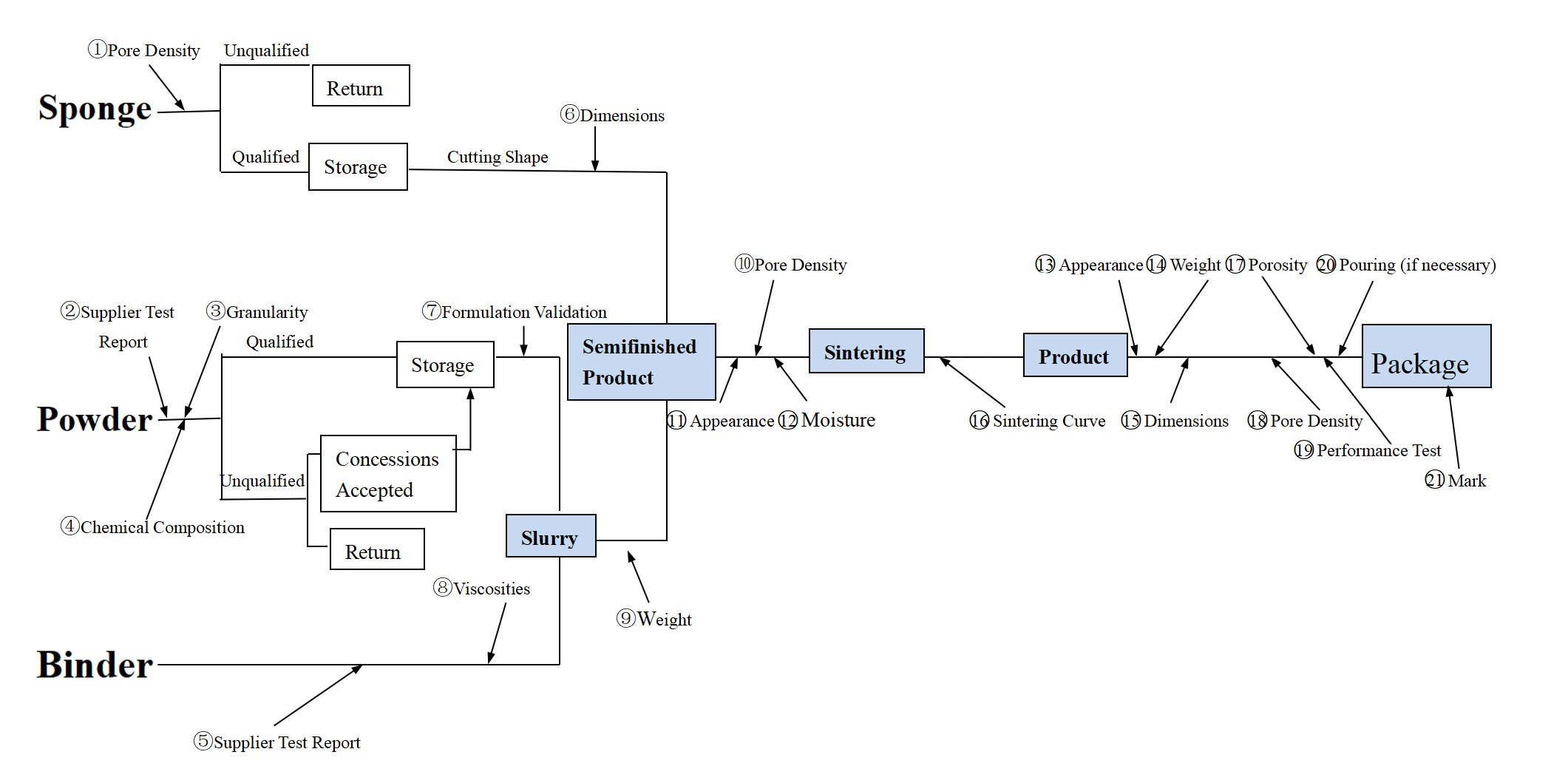

Organic foam impregnation is a process for preparing porous ceramic materials, mainly used to make ceramic foam filters. The following are the detailed steps and characteristics of the process:

1. Process steps

Select organic foam:

Use organic foam with open-cell structure (such as polyurethane) as a template.

Prepare ceramic slurry:

Mix ceramic powder (such as alumina, silicon carbide) with binder, dispersant, etc. to make a uniform slurry.

Impregnation:

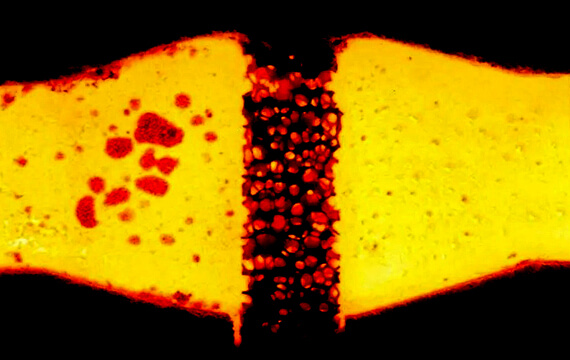

Impregnate the organic foam into the ceramic slurry to ensure that the slurry fully fills the foam pores.

Remove excess slurry:

Remove excess slurry by squeezing or centrifugation to prevent pore clogging.

Drying:

Dry at room temperature or low temperature to solidify the slurry.

Sintering:

High temperature sintering, burns off the organic foam and densifies the ceramic skeleton to form porous ceramics.

2. Process characteristics

- High porosity: It can replicate the open-cell structure of organic foam and has high porosity.

- Controllable pore size: The pore size can be adjusted by selecting different foam templates.

- Complex shape: Suitable for manufacturing porous ceramics with complex shapes.

- Low cost: Simple process, suitable for large-scale production.

3. Applications

Ceramic foam filter: Used for molten metal filtration.

Catalyst carrier: Used as a catalyst carrier in chemical reactions.

Biomaterials: Used as bone tissue engineering scaffolds.

4. Advantages

Simple process and low cost.

Materials with high porosity and complex shapes can be prepared.

In summary, the organic foam impregnation method prepares porous ceramic materials with high porosity through impregnation, drying and sintering steps, which are widely used in filtration, catalysis and biomaterials.

Are you looking for a reliable ceramic foam filter manufacturer? SF-FOUNDRY is a ceramic foam filter manufacturer that uses the organic foam impregnation method to produce porous ceramic filter products. Choose SF-FOUNDRY to be your reliable supplier.

- Email: info@sf-foundry.com

- WhatsApp: +8613785803358