Among the various filtration techniques available, Silicon Carbide Ceramic Foam Filters stand out as a superior option with a multitude of advantages over traditional iron filtration methods. In this blog post, we delve into the unique characteristics of Silicon Carbide Ceramic Foam Filters in iron filtration, and the distinct advantages they offer compared to other iron filtration methods.

Understanding Silicon Carbide Ceramic Foam Filters

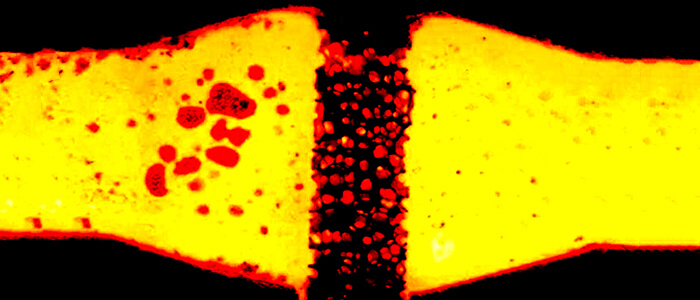

Silicon Carbide Ceramic Foam Filters are advanced ceramic casting filters designed to remove impurities from molten metal during the casting process. These filters are made from silicon carbide, a material known for its exceptional thermal stability and chemical resistance. The porous structure of the foam filter allows for effective filtration of inclusions, slag, and other contaminants present in the molten metal, ensuring cleaner and higher-quality castings.

The Role of Silicon Carbide Ceramic Foam Filters in Iron Filtration

In iron filtration processes, Silicon Carbide Ceramic Foam Filters play a crucial role in improving casting quality. These filters effectively capture and retain impurities such as oxides, slag, and non-metallic inclusions, preventing them from entering the mold cavity. By promoting cleaner metal flow, reducing turbulence, and enhancing solidification, Silicon Carbide Ceramic Foam Filters contribute to the production of defect-free castings with superior mechanical properties and surface finish.

Advantages of Silicon Carbide Ceramic Foam Filters over Other Iron Filtration Methods

- Improved Filtration Efficiency: Silicon Carbide Ceramic Foam Filters offer higher filtration efficiency compared to traditional methods, effectively removing a wide range of impurities from the molten metal.

- Enhanced Casting Quality: By reducing the presence of inclusions and contaminants, these filters contribute to the production of high-quality castings with minimal defects.

- Consistent Performance: Silicon Carbide Ceramic Foam Filters provide consistent performance over time, ensuring reliable filtration results and stable casting processes.

- High Thermal Stability: The heat-resistant nature of silicon carbide allows these filters to withstand high temperatures, making them ideal for demanding casting applications.

- Cost-Effective: While initially a higher investment, the long lifespan and efficiency of Silicon Carbide Ceramic Foam Filters make them a cost-effective choice in the long run.

- Versatility: These filters are suitable for a wide range of iron casting processes, including gray iron, ductile iron, and steel casting.

In conclusion, Silicon Carbide Ceramic Foam Filters offer a host of advantages that make them a preferred choice in iron filtration processes. Their superior filtration efficiency, enhanced casting quality, and durability set them apart from traditional filtration methods, making them an indispensable tool for achieving excellence in metal casting operations.

By incorporating Silicon Carbide Ceramic Foam Filters into iron casting processes, manufacturers can optimize their operations, improve casting quality, and elevate overall efficiency in the production of high-quality castings.