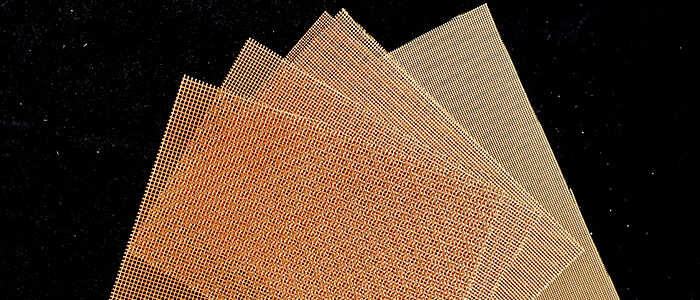

In the realm of aluminum casting, the utilization of fiberglass mesh filters plays a pivotal role in enhancing casting quality and efficiency. Fiberglass Mesh Filter for Aluminium, commonly referred to as aluminum mesh, comes in three primary variations: standard, smokeless, and carbonized. Let’s delve into the distinctions among these variants and their respective applications in aluminum casting processes.

Standard Fiberglass Mesh Filter:

The standard fiberglass mesh filter embodies typical characteristics and performance attributes. It functions in casting processes by providing filtration, support, and reinforcement. This type is suitable for manufacturers with general aluminum casting requirements and customers with standard performance expectations.

Smokeless Fiberglass Mesh Filter:

The smokeless fiberglass mesh filter is engineered using smokeless treatment techniques. By controlling combustion temperatures, incorporating special additives, or employing unique heat treatment processes during production, this variant minimizes or eliminates smoke generation. Operating efficiently at high temperatures without emitting harmful gases or smoke, it aligns with stringent environmental standards. It caters to environmentally conscious enterprises or clients adhering to strict environmental regulations, particularly in precision casting industries.

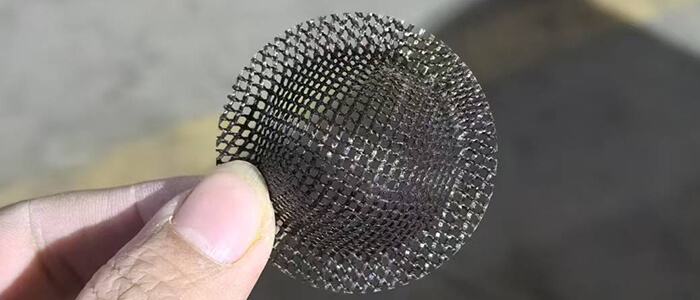

Carbonized Fiberglass Mesh Filter:

The carbonized fiberglass mesh filter undergoes carbonization treatment by subjecting the fiberglass mesh to high-temperature furnaces. Typically, carbon sources such as carbides induce carbonization reactions on the fiberglass, forming a protective carbonized layer on its surface. This variant boasts enhanced high-temperature resistance and corrosion resistance, making it ideal for enterprises employing high-temperature aluminum casting processes or clients with specialized requirements. For applications like piston manufacturing, this filter ensures the quality of pistons remains uncompromised.

In conclusion, the selection of the appropriate fiberglass mesh filter variant is crucial in optimizing the aluminum casting process. Each type – standard, smokeless, and carbonized – offers distinct advantages tailored to specific casting needs, environmental considerations, and high-temperature casting requirements. Understanding these differences enables manufacturers and clients to make informed decisions, enhancing the efficiency and quality of their aluminum casting operations.

For premium quality fiberglass mesh filters for aluminum casting, reach out to SEFU, the trusted supplier specializing in customized solutions to meet your unique casting requirements.

- Email: info@sf-foundry.com

- WhatsApp: +8613785803358