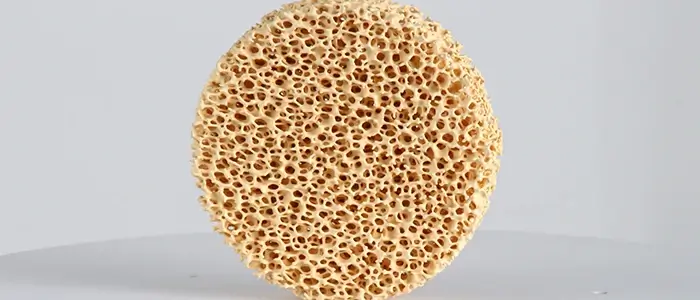

In the intricate world of steel manufacturing, precision and quality are paramount. Enter Zirconia Ceramic Foam Filters, a cutting-edge innovation that has reshaped the landscape of steel production. These advanced filters, crafted from zirconia ceramics in a foam-like structure, have become indispensable tools for enhancing the purity and quality of molten steel. This industry knowledge blog explores a compelling application case study, shedding light on the transformative impact of Zirconia Ceramic Foam Filters in the realm of steel production.

Introduction: The Evolution of Steel Filtration Technology

Zirconia Ceramic Foam Filters represent a significant leap forward in steel filtration technology. With their ability to efficiently remove impurities and minimize gas entrapment, these filters have become instrumental in improving the quality and efficiency of steel manufacturing processes.

Case Study: Steel Manufacturer in Malaysia Success with Zirconia Ceramic Foam Filters

Steel Manufacturers in Malaysia, a player in the steel industry, embarked on a journey to enhance the quality of their steel products and streamline their production processes. By incorporating Zirconia Foam Filters into their operations, the manufacturer witnessed a remarkable transformation in their steel manufacturing practices.

Results: A Paradigm Shift in Steel Quality and Efficiency

The integration of Zirconia Ceramic Foam Filters at Steel Manufacturer in Malaysia led to a substantial improvement in the cleanliness and purity of their molten steel. This translated into higher-quality metal outputs, reduced instances of defects, and enhanced casting precision. The manufacturer experienced a tangible enhancement in the overall quality and efficiency of their steel production.

Benefits Realized by Steel Manufacturers in Malaysia

- Enhanced Product Quality: The utilization of Zirconia Foam Filters resulted in superior-quality steel products that met stringent industry standards.

- Operational Efficiency: The filters optimized the steel manufacturing process, leading to increased operational efficiency and productivity gains.

- Cost Savings: Reduced defect rates and improved product quality translated into cost savings for Steel Manufacturers in Malaysia.

Conclusion: The Future of Steel Production Enhanced by Zirconia Ceramic Foam Filters

In conclusion, the application of Zirconia Ceramic Foam Filters in steel production signifies a significant advancement in the industry. As steel manufacturers strive for excellence and seek ways to enhance their processes, these filters emerge as indispensable tools for achieving superior quality, reducing defects, and driving operational efficiency.

The success story of the Steel Manufacturer in Malaysia underscores the transformative potential of Zirconia Ceramic Foam Filters in the steel manufacturing sector. By embracing innovation and leveraging cutting-edge technologies like these filters, steel manufacturers can position themselves at the forefront of the industry, setting new standards for quality, efficiency, and sustainability in steel production.